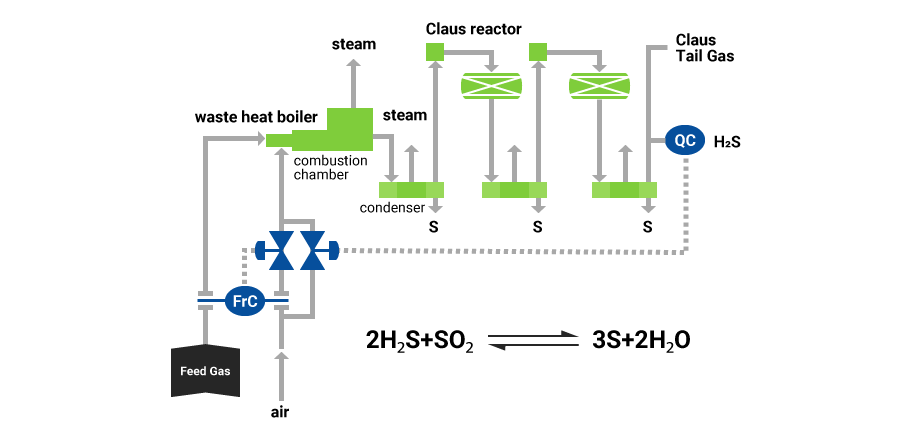

Sulfur Recovery Unit (SRU)

H2S removed in the AGR process is sent to the sulfur recovery unit (SRU) as acid gas. SRU recovers H2S as elemental sulfur through the Claus reaction (see the attached figure). Reactions occur in two stages: the flame reaction stage and the catalytic reaction stage. The former consists of a high-performance burner, mixing chamber, and heat removing boiler, while the latter has two to three reactor stages. The sulfur recovery rate of the Claus process is about 95 to 97%. The tail gas that contains unrecovered sulfur is fed to the tail gas treating unit (TGT). The recovered sulfur is stored in the sulfur pit and shipped as product after undergoing a degassing process to remove H2S. The Claus process is an equilibrium process, and a modified version of it with direct oxidation catalysts stored in the final stage is called subERCLAUS. Since this improved process does not depend on Claus equilibrium, it can attain a 99% recovery ratio without TGT (Licensor: Jacobs Comprimo). It is important for the Claus process that appropriate burners be selected and use the right catalysts to ensure high recovery rate and long service life.

Capabilities

- Chiyoda can do the design work by ourselves as we have sufficient knowledge and experience to design the unit such as to select burners and catalysts and design mixing chambers, etc.

- By using TGT process, 99.2% recovery can be achieved.

Applicable range

Gases with H2S content of over 25% are suitable for the recovery of sulfur in Claus process.