Synthesis Gas

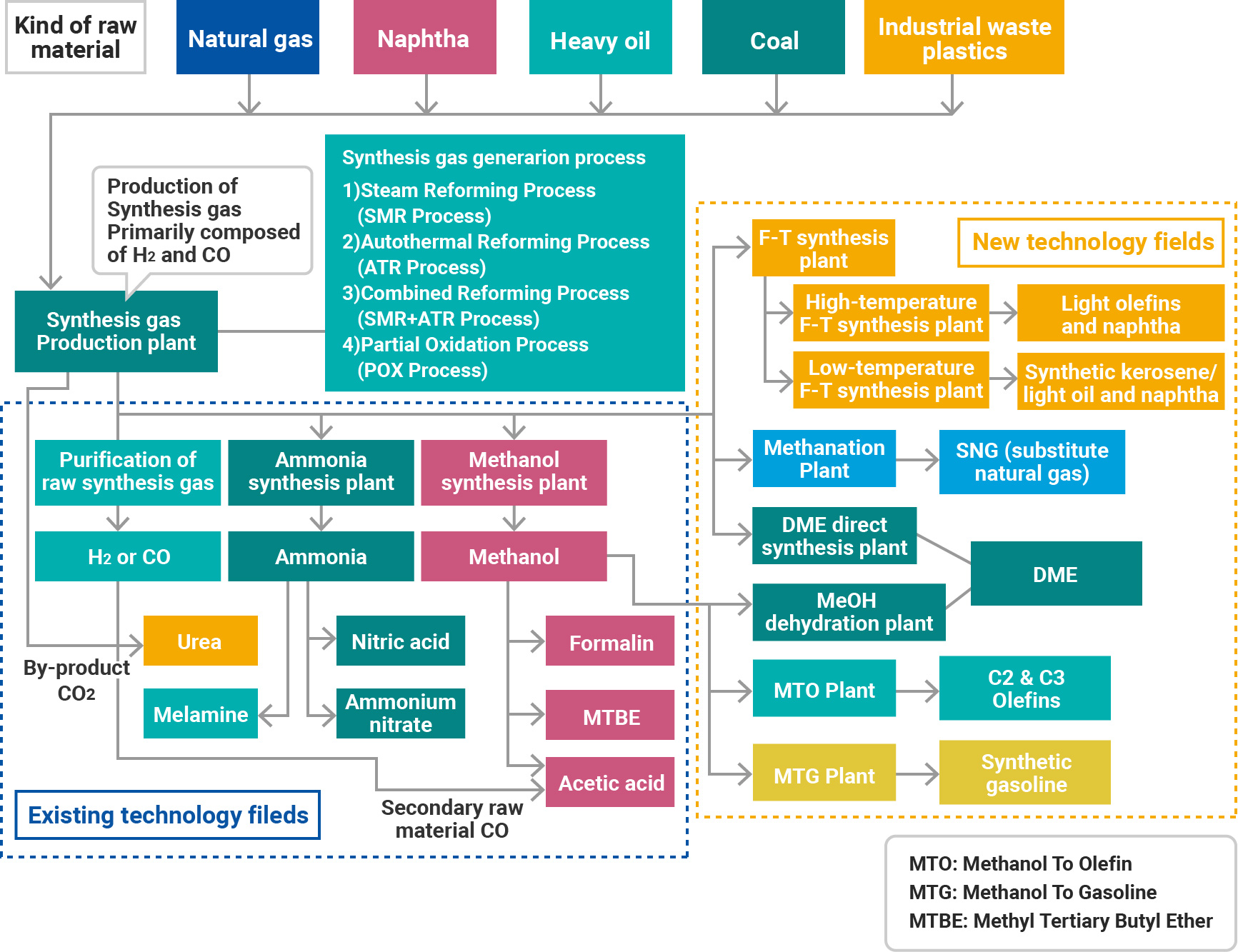

‘Synthesis Gas’ is a general term for raw gas that predominantly consists of hydrogen (H2) and carbon monoxide (CO), but may also contain carbon dioxide (CO2) and methane. The term also refers to feedstock gas used in the production of ammonia, methanol, oxo synthesis, synthetic oil (Gas To Liquid (GTL)), dimethyl ether (DME), substitute natural gas (SNG) and hydrogen manufacturing.

Although Synthesis Gas can be produced from hydrocarbons, it has more recently been produced from carbon dioxide (CO2) and hydrogen (H2) derived from renewable energy as a raw material for producing synthetic fuels (e-fuel). E-methane is produced by methanation and is becoming a focus of interest.

Synthesis Gas production requires the application of the requisite synthesis gas production technology according to the type of raw material, depending on final product specifications, equipment capacity and other factors. Chiyoda provides optimal and proven technologies that meet the requirements of our customers.

Chiyoda also provides a wide range of technologies for the utilization of Synthesis Gas.

Representative technologies for the utilization of Synthesis Gas

Ammonia Synthesis

Ammonia is industrially synthesized from hydrogen and nitrogen using the Haber-Bosch process under high temperature and pressure (400-600°C, 10-20MPaG). The development of synthesis technology under low temperature and pressure is also advancing for ammonia synthesis from hydrogen derived from renewable energy. The main use of ammonia is as a fertilizer but, in recent years, it has garnered attention as an energy source for thermal power plants because it does not emit CO2 when burned.

Methanol Synthesis

Methanol is industrially synthesized from Synthesis Gas under high temperature and pressure (200-300°C, 5-10MPaG) and the crude methanol is subsequently purified through distillation. Methanol is used as a raw material for chemicals and for synthesizing gasoline (Methanol to Gasoline (MTG)), and as a marine fuel.

F-T Synthesis

The Fischer-Tropsch reaction (F-T reaction) synthesizes long-chain hydrocarbons (FT crude oil) from Synthesis Gas. FT crude oil, composed of hydrocarbons with different carbon numbers, is refined into products such as gasoline, jet fuel and diesel through an upgrading processes. There has been a focus in recent years on liquid fuels (e-fuel) produced through the F-T synthesis from synthesis gas, which is manufactured via the Reverse Water Gas Shift reaction (RWGS reaction) using CO2 and hydrogen derived from renewable energy.

Chiyoda also offers methanation technology using carbon dioxide and hydrogen as raw materials.