CHIYODA THOROUGHBRED 121 (CT-121) Flue Gas Desulfurization

CHIYODA THOROUGHBRED 121 (CT-121) is the advanced Limestone Forced Oxidation (LSFO) Flue Gas Desulfurization (FGD) Technology and proven by so many commercial experiences in the large thermal power plants, worldwide.

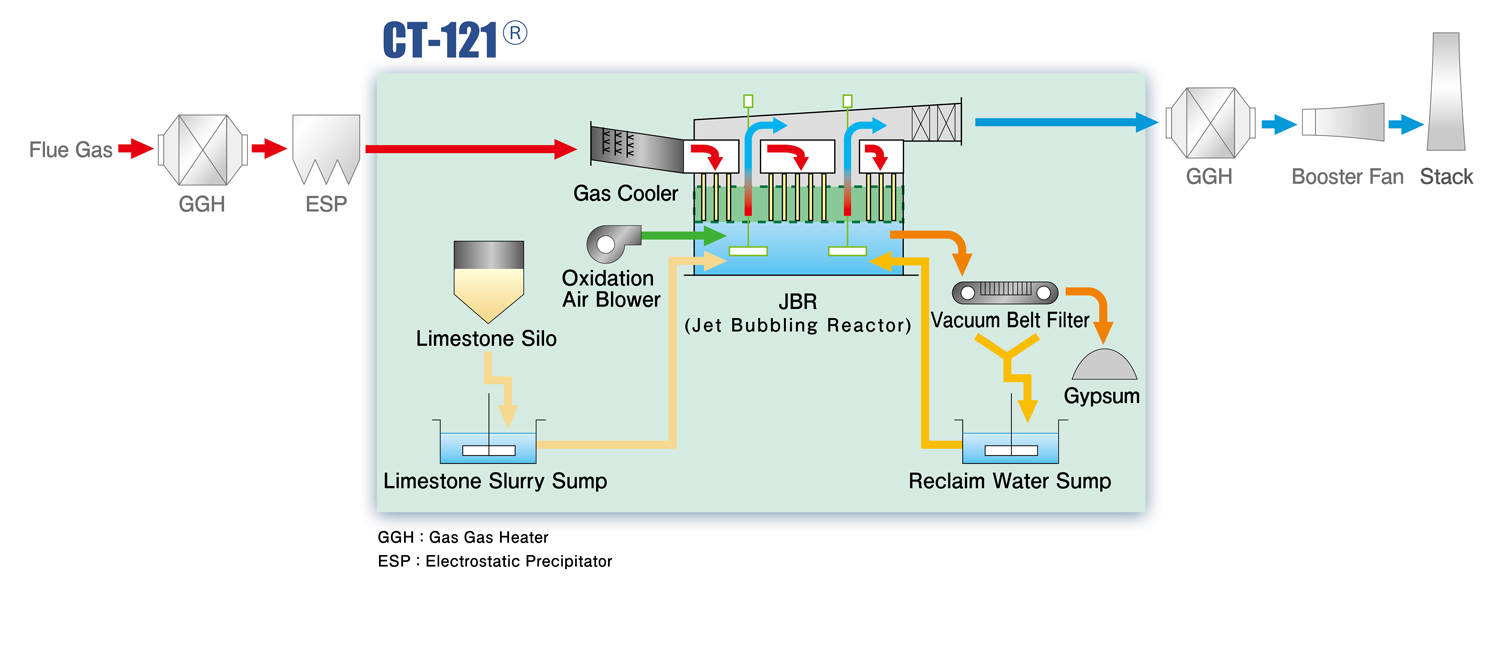

Process Flow

1. Absorption, Oxidation, Neutralization and Crystallization

The heart of the CT-121 FGD process is the unique Jet Bubbling Reactor (JBR). All necessary steps for SO2 absorption, oxidation, neutralization and crystallization occur simultaneously in the JBR. The flue gas is dispersed into the scrubbing liquid through multiple gas sparging tubes, creating small bubbles which are broken by the liquid’s motion. Oxidation, neutralization, crystallization occur in the reaction zone, the main area for liquid phase of JBR. Air and limestone are dissolved into the liquid through bubbling and agitation. The gypsum crystals grow to the desired size after sufficient residence times and the gypsum slurry is drawn off. The clean gas passes through JBR and mist eliminator is released to the atmosphere.

2. Limestone Slurry Preparation Unit

Limestone slurry is prepared by the pulverized limestone and the filtrate from gypsum dewatering unit and fed to JBR to neutralize the JBR liquid.

3. Gypsum Dewatering Unit

The gypsum slurry from JBR is fed to the gypsum dewatering system and by-product gypsum is produced. The filtrate of gypsum slurry is reused to prepare the limestone slurry.

Chiyoda Thoroughbred 121 (CT-121) Flue Gas Desulfurization Plant

Capabilities

- Low Construction and Maintenance Costs

Compact design due to low JBR height and simple design without large liquid circulation pumps save construction and maintenance costs. - Low Operation Costs

Low power consumption and easy operation & maintenance due to mechanically simple design result in minimal staffing requirements and low operation costs. - High Reliability

Almost 100% reliability for all existing plants. - High Flexibility

High SO2 removal efficiency is achievable at wide inlet SO2 concentration range, and allow for fuel flexibility consequently. - Easy Load following operation

Wide Turn down capability. - Additional Benefits

・High particulate removal

・High Air Toxics removal

・High quality byproduct gypsum

Applicable range

- Flue gas exhausted from coal-fired or oil-fired boiler, non-ferrous industry etc.

- Fule gas pre-treatment for CO2 Capture and Storage (CCS).