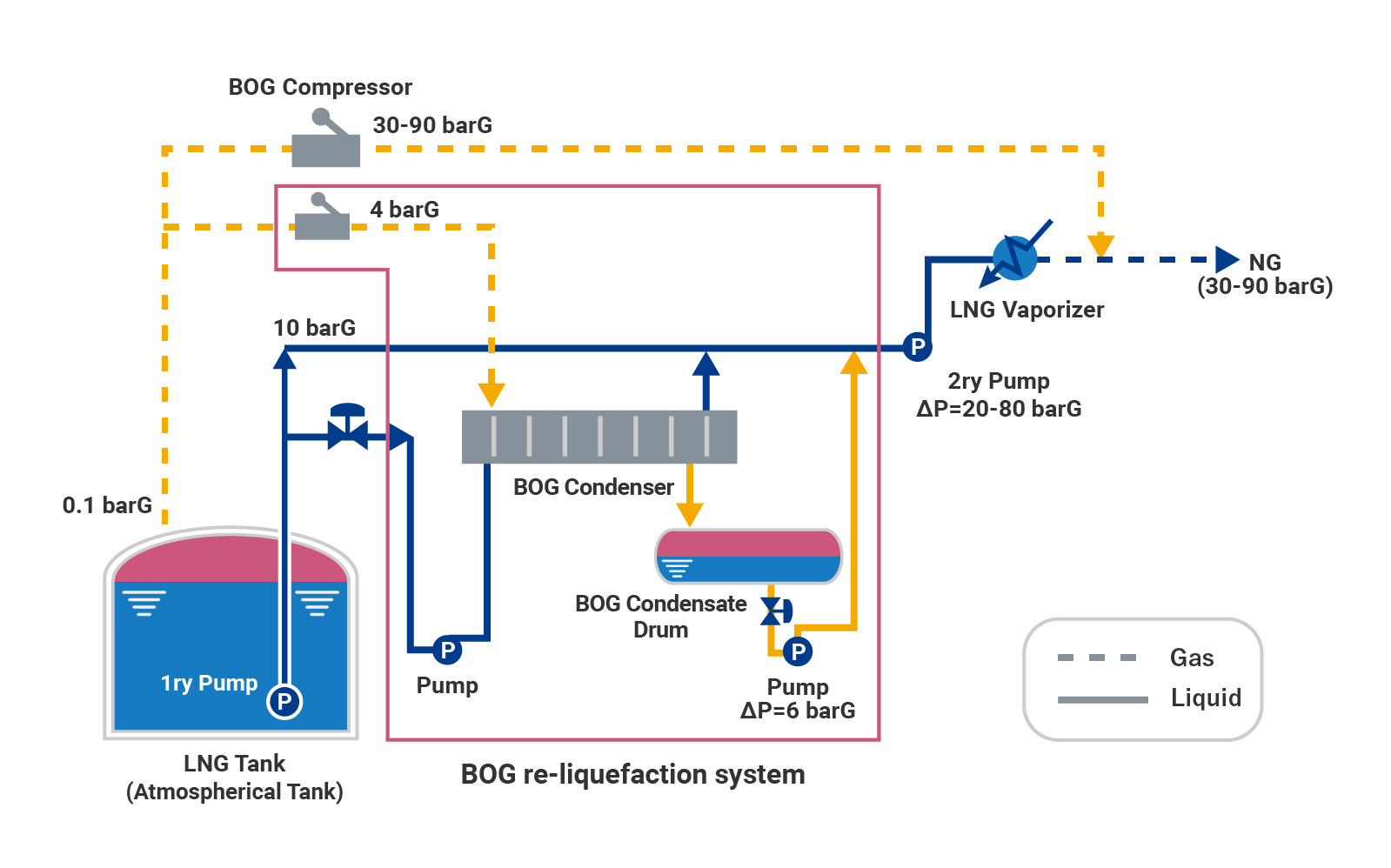

BOG Re-liquefaction System

Gasified LNG by inevitable heat input from external area is referred to as boil off gas (BOG). BOG is conventionally pressurized with compressor and then sent as city gas or fuel for power generation together with LNG gas vaporized by heat exchanger. BOG re-liquefaction technology using LNG cold energy has been established as one of other gas treatment methods. In case of gas supposed to be sent as city gas or fuel for power generation, gas pressure reaches 30 to 90 barG while pressure of BOG going to re-liquefaction facility is lower than 10 barG. Therefore, addition of re-liquefaction facility decreases the size of BOG compressor to reduce operational power, which leads to energy conservation. The scheme below describes the method with lowest energy consumption among various methods.

≪Indirect heat exchange method≫

Discharge pressure at BOG compressor can be reduced to 3-5 barG to realize energy conservation.

(Note that BOG pump is necessary after its condensation)

Capabilities

Merits cited below can be expected by means of the application of re-liquefaction system technology to LNG terminals.

- Suppression of stored LNG condensation by the recovery of re-liquefied BOG

- Energy conservation by the reduction of compressor power

- Best selection of BOG re-liquefaction facilities.

Applicable range

General LNG terminal