Planning Phase

For clients who intend to create new project, we will provide our services for studying and planning of projects in the following areas.

Master Planning

PNG LNG Project, Papua New Guinea,

Courtesy of ExxonMobil PNG Limited

Chiyoda supports clients to create new projects. For creation of new projects, we prepare proposals, which can maximize clients’ benefit based on leading-edge technology and abundant past experiences.

During the proposal process, we consider various requirements together with the customer in order to achieve optimum profitability. We perform this service not only for LNG, oil refining and petrochemical projects, but also for general industry and production facilities. For the whole energy system of the facility, we make the best proposals in terms of profitability and social environment. We are also taking initiatives with CCS*, which in recent years has gained attention as a measure against global warming.

- CCS (Carbon dioxide Capture and Storage)

Feasibility Studies (FS)

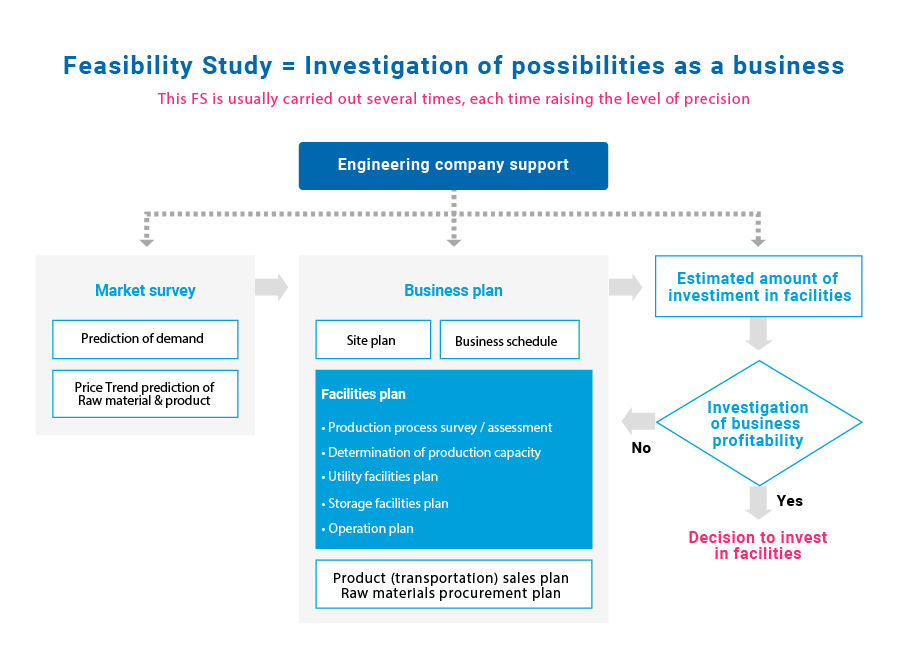

In the case that clients intend to proceed new project, we prepare conceptual design which shows outline of new projects. Based on the blueprint thereby prepared, we carry out feasibility studies (an investigation of its possibilities as a business, abbreviated FS), which considers the profitability or otherwise of the business from various perspectives. Feasibility studies are usually performed in several stages repeatedly and the precision of studies improve. Then finally, clients can proceed next steps, if it is judged that new projects can yield high profitability.

Based on its abundant record of achievement in plant construction in various fields, Chiyoda, taking the initial stage of the feasibility study as its starting point and commencing with a market survey, selects the production process, investigates the optimum configuration for process utility equipment, calculates equipment and operating costs, and produces an optimized highly economical proposal that considers the entire plant lifecycle.

Feasibility studies carried out by Chiyoda possess the following special characteristics:

- We propose a process selection and optimum equipment configuration that meets the needs of the customer.

- We give a highly accurate estimate of construction costs based on data from an extensive record of achievement in construction projects.

- We provide an efficient investigation supported by engineers of long experience and a rich fund of data.

Process Development Support

Smart Scale-Up Engineering Proposals

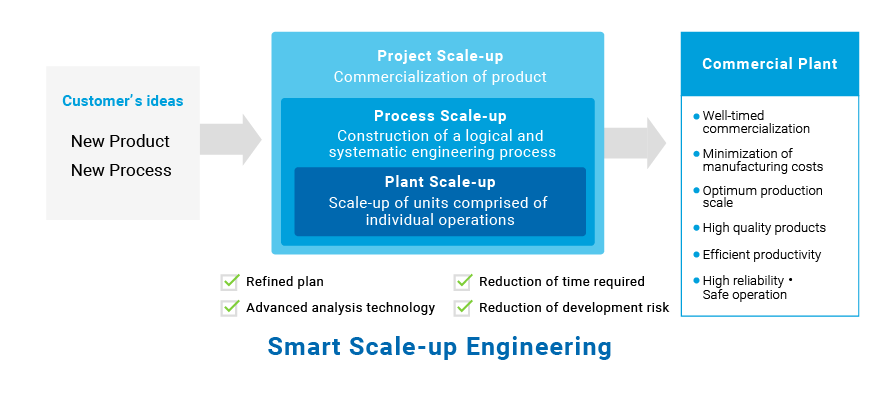

In commercial plants, well-timed commercialization, optimum scale of commercial production, minimization of manufacturing costs, efficient production of high quality products and high reliability etc. are required.

In order to guide ideas at the research and development level through to realization as commercial plants, Chiyoda, while organizing and systematizing the various necessary technologies and furthermore introducing new world leading analysis technology, has developed and implemented more efficient commercialization support methods. “Scale-up engineering” is Chiyoda’s comprehensive technology for raising a process from the research and development scale to that of a commercial production scale plant, in a rational manner, looking from the customer’s point of view. With this scale-up engineering, Chiyoda, from its foundation through to the present day, has aided in guiding the technologies developed by its customers through to the realization of actual commercial plants in a wide range of fields, such as petroleum, petrochemicals and chemistry etc. We have handled more than one hundred such projects. In the future also, we aim to understand the needs of our customers, provide scale-up engineering that will realize the maximum potential of their technological innovations, and progress in line with their expectations.

Scale-up Engineering

Comprehensive technology for taking a process from the research and development scale to the commercial production scale plant, in a logical and systematic manner, while always considering the customer's needs and requests.

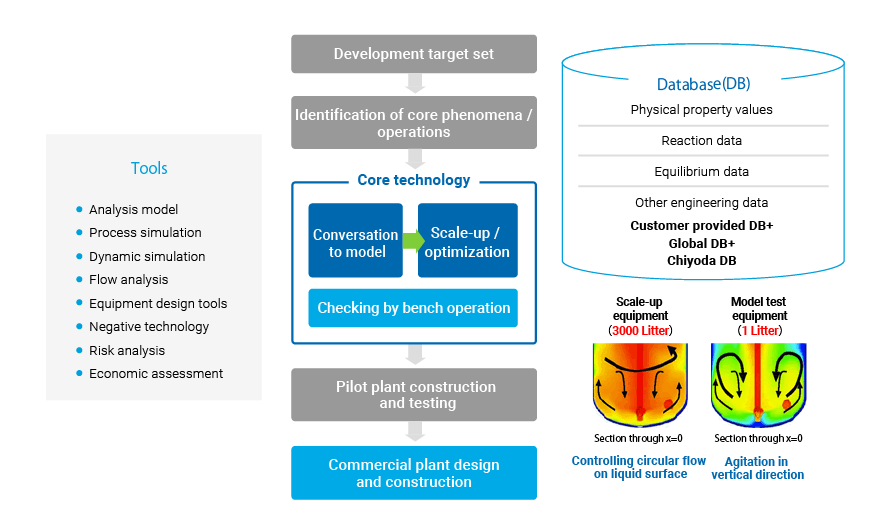

Scale-up Engineering Process