EUREKA Process

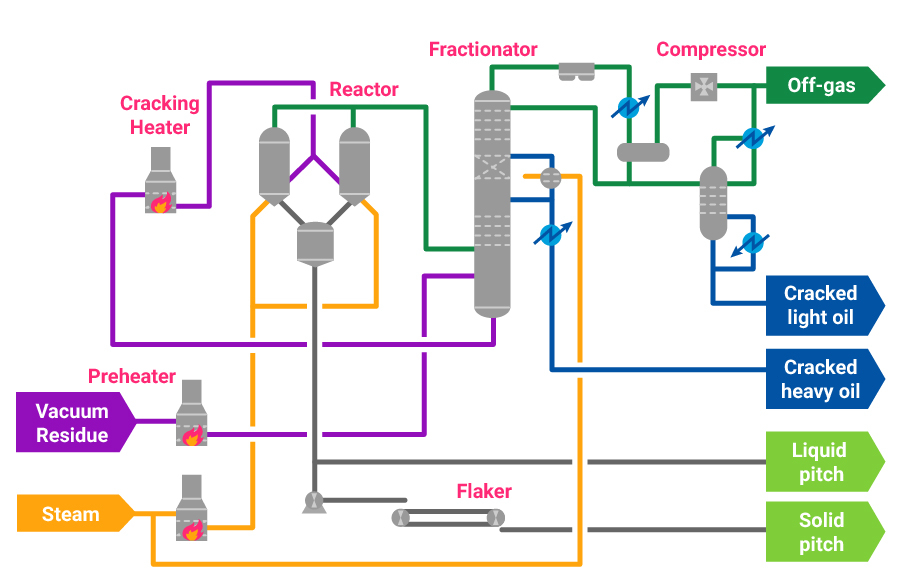

The EUREKA® process is a commercially proven thermal cracking with semi-batch reactor systems to produce valuable cracked oil and aromatic petroleum pitch from heavy residual material. It meets the strong needs "more value, less bottom" in recent petroleum refining industry.

All off gas from the process is used as a fuel gas in the system after desulfurization. The cracked vapor is fractionated in fractionator into cracked light oil and cracked heavy oil. which become gasoline and diesel oil. Pitch is utilized in a steel industry as a binder for non-coking coal which is an alternative of coking coal. The pitch as liquid feedstock to a gasification process becomes more attractive from the environment and operability points of view.

The first commercial plant was constructed in the Fuji Oil Company, Ltd. at Sodegaura in Japan and has been operating for more than 30 years since then. Through more than 30 years operation in Fuji Oil Refinery, many challenges for improving operability and maintainability has been performed. Chiyoda and Fuji Oil Company are the co-licensors of the EUREKA process.

Capabilities

EUREKA process has features which are clearly different conventional thermal cracking process such as delayed coking, as follows.

Feeding Superheated Steam to the Reactor

The Superheated steam is injected into the reactor not only to supply a part of the reaction heated required but to strip the cracked oil products immediately out of the reactor as produced. Eureka process gives a highly aromatic pitch by controlling the excessive cracking and polycondensation.

Handling Reactor Residues (Pitch) as Liquids

The liquid handling for pitch enables keeping field site clean in comparison with solid coke.

Usable as a Boiler Fuel

Eureka pitch has higher volatile matter and higher heating value with only small amount of ash residue so that it is utilized as boiler fuel without auxiliary fuel. Therefore, ash handling system is not required different from common coal boilers.

Usage as Gasification Feedstock

Charging EUREKA pitch as Liquid feedstock to the gasification process has continuously being proceeded.

Applicable range

EUREKA is one of the best, if you are looking for;

- an upgrading process for residual oil with co-generation of electricity.

- or with hydrogen generation which are reuiqred for desulfurization of oils.

- a process for producing Synthetic Crude Oil (SCO) from ultra heavy crude.