CO2 Reforming Process

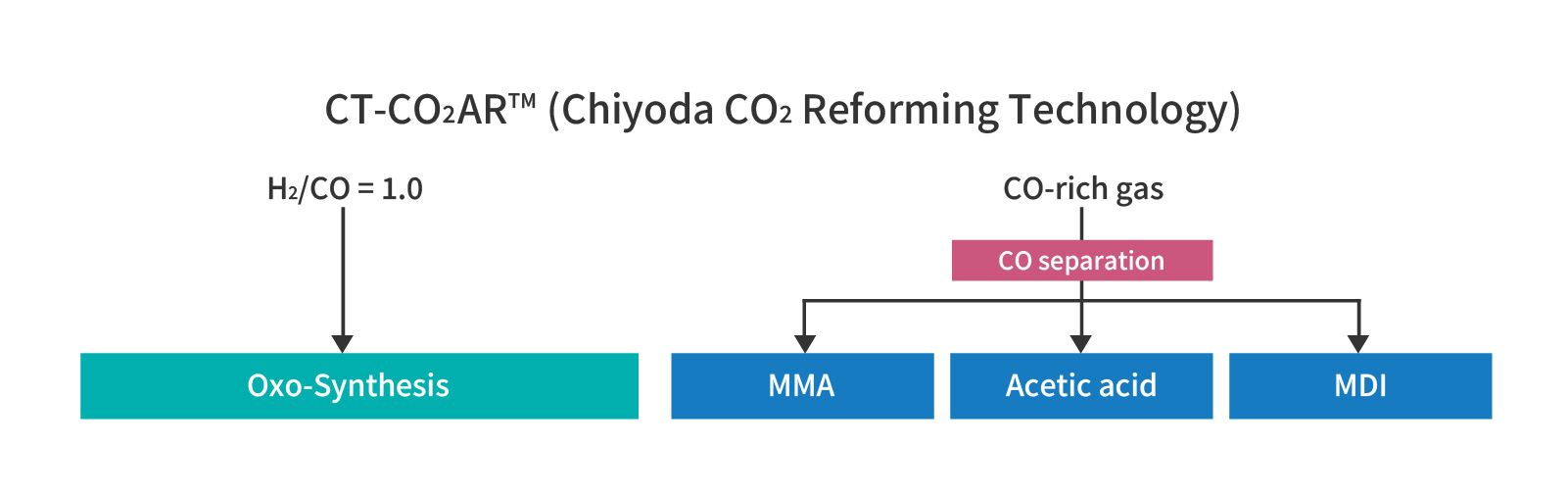

CT-CO2ARTM (Chiyoda CO2 Reforming Technology)

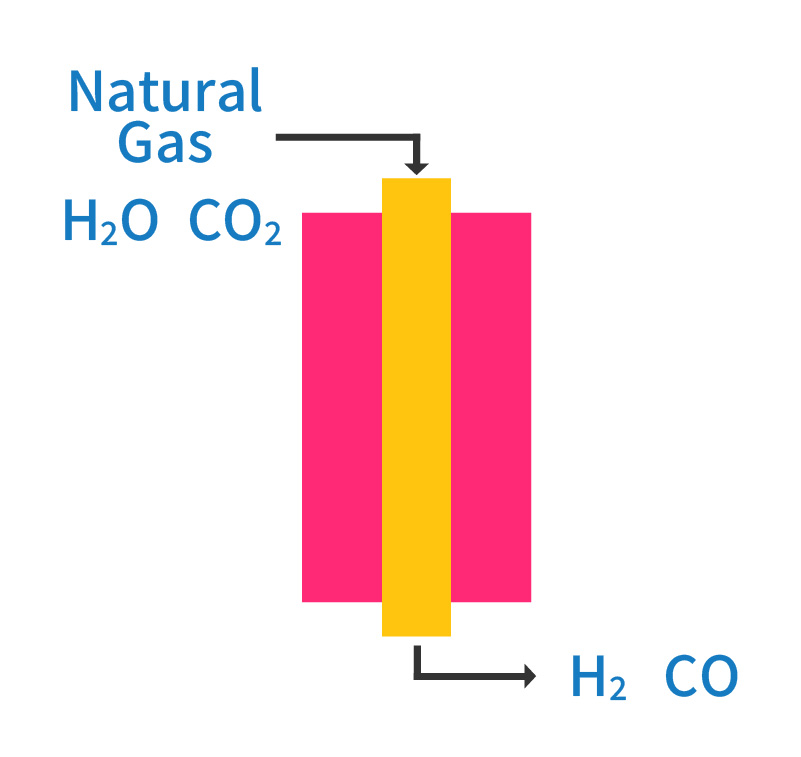

CT-CO2ARTM is a unique and advanced technology utilizing CO2 as a reforming agent to efficiently produce synthetic gases of varying H2/CO ratios

This technology enables the monetization of low-calorie, CO2-containing natural gas fields and can also enable the efficient reuse of CO2 emitted from various industrial processes.

Synthesis gases are the feeds for producing various chemicals (Oxo-Synthesis, MMA, Acetic acid, etc.).

The CT-CO2ARTM technology consumes CO2 as a reforming agent and in tandem with its unique reforming catalyst, achieves high energy-efficiency. CT-CO2ARTM is thus, an environmentally-friendly technology due to significant reduction in emissions.

Capabilities

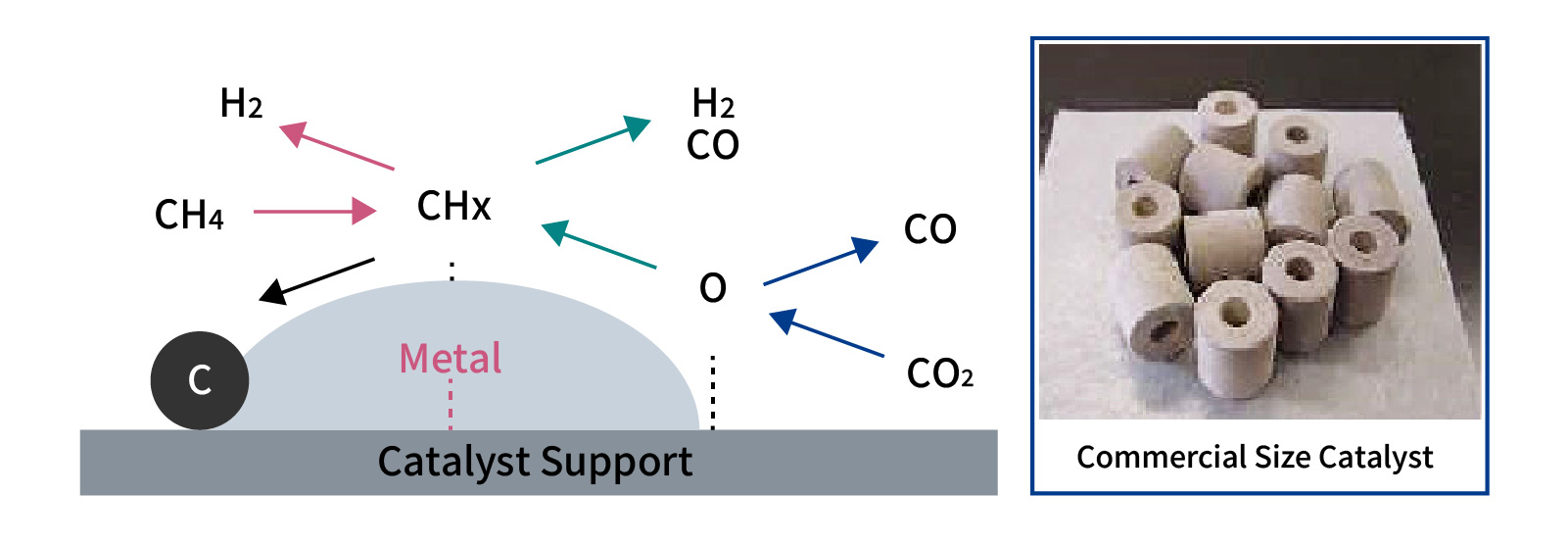

Synthesis gas production under optimum conditions with a novel catalyst

Chiyoda’s proprietary catalyst, having high resistance to carbon formation (even under CO2 reforming conditions), results in significant reductions in the requirement of steam and CO2. Consequently, CT-CO2ARTM produces synthesis gases with high energy-efficiency and without any carbon formation.

High energy-efficiency and cost competitiveness

Compared to conventional steam-reforming, CT-CO2ARTM reduces the volume of reformer feed gas by 60%. This results in improved energy efficiency together with a significant reduction of capital investment, operating costs and CO2 emissions. Specifically, for production of syngas with an H2/CO ratio of 1.0, capital costs are reduced by more than 20% compared with conventional technologies. For an H2/CO ratio of 0.5, the reduction is even more significant, exceeding 40%. CT-CO2ARTM is thus economically competitive.

Applicable range

Direct production of Synthesis gases with a wide range of H2/CO ratios

Direct production of synthesis gases with a wide range of H2/CO ratios is efficiently accomplished using CT-CO2ARTM, by varying the feed gas ratios such as steam/carbon ratio and CO2/carbon ratio.