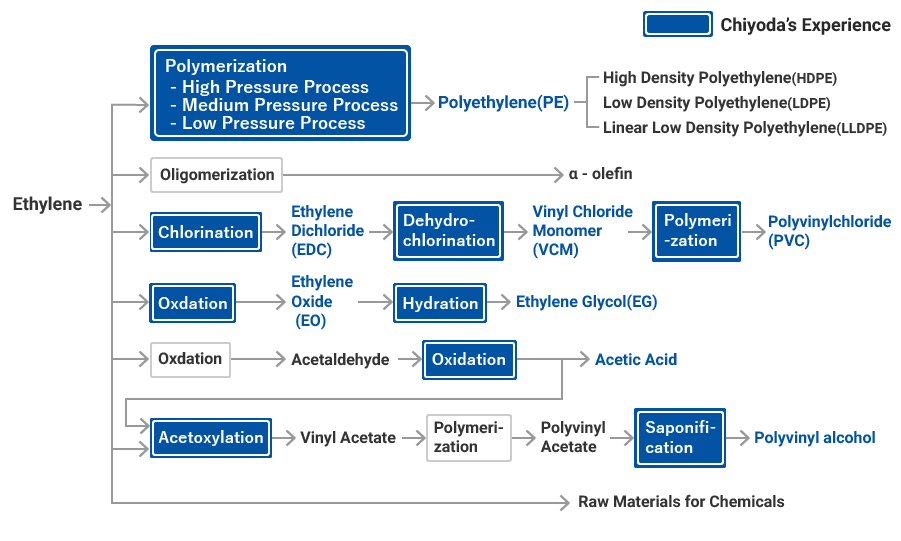

Ethylene Derivatives

Ethylene, which has a carbon–carbon double bond, is one of the most important fundamental chemicals in the petrochemical industry as it is the source material for a variety of products such as polyethylene resin, ethylene glycol, vinyl chloride resin, acetic acid, styrene, and alpha olefin which are produced by polymerization, oxidation, alkylation, hydration, or the addition of halogen.

[ Ethylene and Its Derivatives ]

Capabilities

Polyethylene Process

Polyethylene is among the most widely applied resins because of its excellent balance between quality and cost. Its polymerization method is classified into two types: the high-pressure process and the medium- and low-pressure process. The latter is further divided into the slurry process, solution process, and gas-phase process. Products produced from polyethylene are largely categorized into high-density polyethylene, low-density polyethylene, and linear low-density polyethylene. Production processes are appropriately combined depending on the product characteristic.

Key projects

Since we started constructing polyethylene plants in the latter half of the 1960s, we have completed a lot of plant projects. We advanced to foreign countries in the first half of the 1980s to execute large plant construction projects.

We are a core contractor of the Innovene process, which is a medium- and low-pressure and gas-phase process.

We have also constructed many ethylene oxide/ethylene glycol (EO/EG) plants since the first half of the 1960s in Japan. In the Middle East, we constructed several large EO/EG plants. There is large growth in worldwide demand for ethylene glycol, which is an important raw material for polyester fiber and PET resin.