Process Dynamic Simulation / Water Hammer Analysis

Process Dynamic Simulation

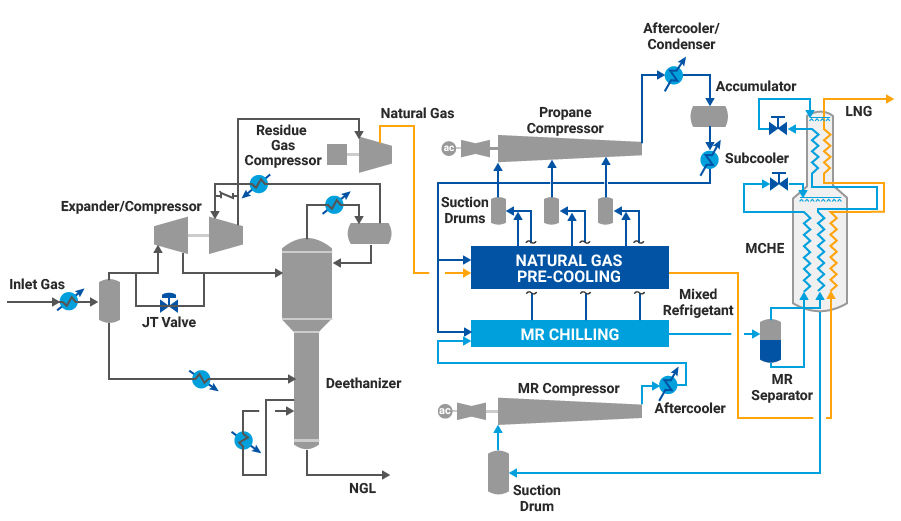

Chiyoda provides solutions, based on advanced simulation technologies, aimed at analyzing and examining the impact of a plant’s startup, shutdown, operating mode change and equipment failure or shutdown, on system behaviors and process conditions. Process dynamic simulation is essential for undertaking system operability and controllability assessments, safety measures, equipment sizing and appropriate control system designs from the standpoint of dynamic operation of the plant.

The appropriate tool is selected in accordance with the subject and contents of the study. For simulation modeling, we use all required data such as equipment size, moment of inertia, performance characteristics of the equipment, capacity and resistance of pipes and vessels, flow characteristics of the valves and valve stroke speed, to simulate actual phenomena with superior precision.

The range of models we study has been increasing in complexity and expanding in line with the advancement of computers and tools. Dynamic simulation is also applied to designing large-scale systems, such as a plant as a whole.

Example of Process Dynamic Simulation Model Scope (LNG Plant)

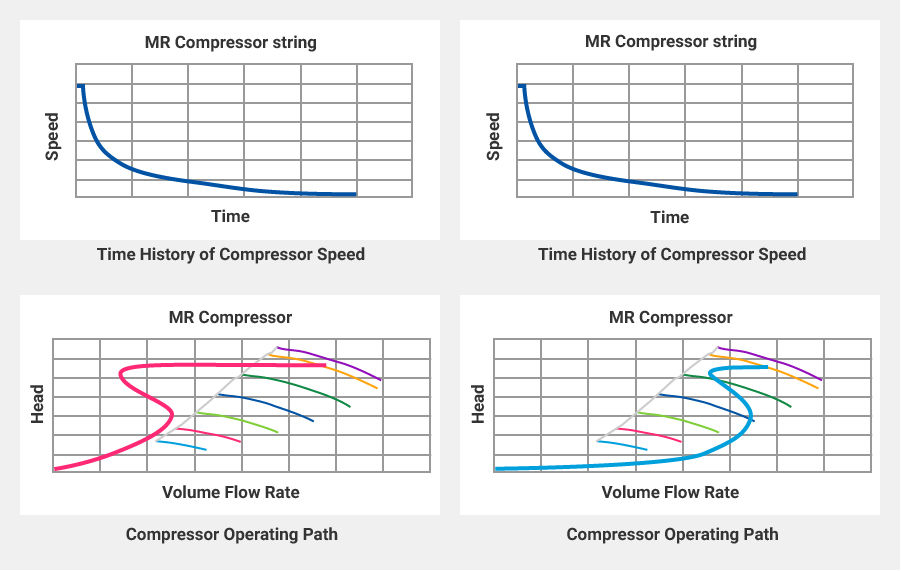

Example of Process Dynamic Simulation Results (Compressor Trip)

Water Hammer Analysis (Hydraulic Surge Analysis)

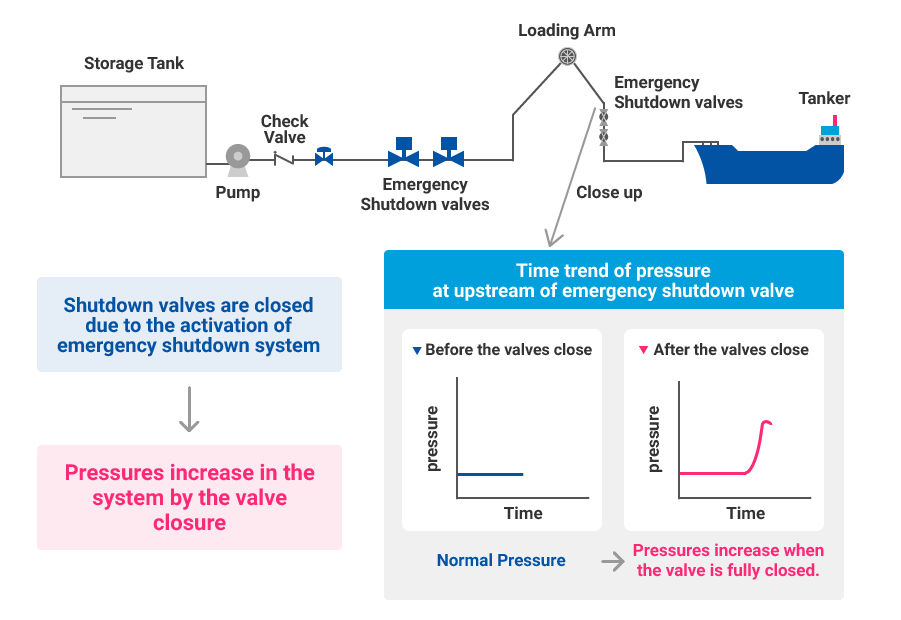

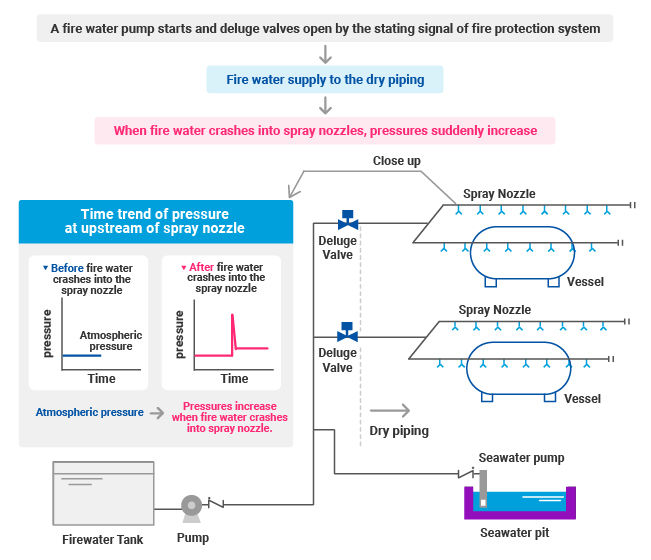

Water Hammer Analysis (Hydraulic Surge Analysis) is performed to verify the operability and safety of the plant during emergency shutdowns or unsteady operation. In a pipeline for transporting liquid, steep changes of pressure due to a sudden change in velocity caused by opening/closing of a valve, startup/shutdown of a pump etc could lead to very high pressure. This phenomenon is called a water hammer or a surge. Surge phenomena is often observed in a long pipeline, such as feed receiving lines and product loading lines, and in fire protection systems where operation is not continuous.

This surge phenomenon could rise the pressure much higher than normal operating pressure, causing damage to piping, supports and equipment. Chiyoda has been performing surge analysis on various plants since the 1970's to evaluate surge impacts. Recently, surge analysis is applied, not only to newly developed plants, but also to existing plants due to a change in feed composition and operation method.

Example 1)Water Hammer phenomena at Loading operation

Example 2) Water Hammer phenomena at Deluge system

Capabilities

Process Dynamic Simulation

- When applying new concepts to a plant or scaling-up, unexpected problems often occur. By utilizing dynamic simulation, effects of design change are verified without damaging actual facilities.

- Dynamic simulation verifies the operability of a plant during a disaster, such as total power failure following an earthquake. Flaring load from each system after failure is also verified considering the dynamics of equipment operation.

Water Hammer Analysis (Hydraulic Surge Analysis)

- Evaluation of surge pressure due to emergency shutdown or unsteady operation of a facility has contributed to the safe design and operation of plants.

- Chiyoda has over 40 years of experience in Surge Analysis using the verified surge analysis program, meaning we can ensure high reliability analyses and recommend practical solutions based on results.

- HYTRAC is our proprietary computer program that utilizes the characteristic method. Comparisons using a large amount of field data on multiple systems and phenomena, such as valve closures, pump trips and pump variable speed control, enables accurate analysis.

- As the result of analysis, the historical data (time trend data) of pressure, flow rate, velocity and surge force acting on each piping are utilized to provide the practical solutions for safety design.

Applicable range

Process Dynamic Simulation

- Refrigeration Systems: Ref compressor trips and restart simulations with determination of bypass valve requirements. Parallel compressor trips, restarts, and tie-ins after restart.

- Liquefaction Systems: Estimating time trends of LNG temperature following shutdown of main cryogenic heat exchanger.

- Steam Systems: Steam turbine trips and restarts. Steam user trips.

- Fuel Gas Systems: Fuel Gas Compressor trips.

- Emergency blow down system including flare etc.

Surge Analysis

Surge analysis can be applied in various liquid piping systems such as oil refining, petrochemical, gas, chemical plant.

- Loading/Unloading system

- Liquid transfer system

- Cooling water system

- Industrial water system

- Fire water system

- Pipeline etc.