Heat and Fluid Dynamics Simulation Technology

Plant Design Assistance

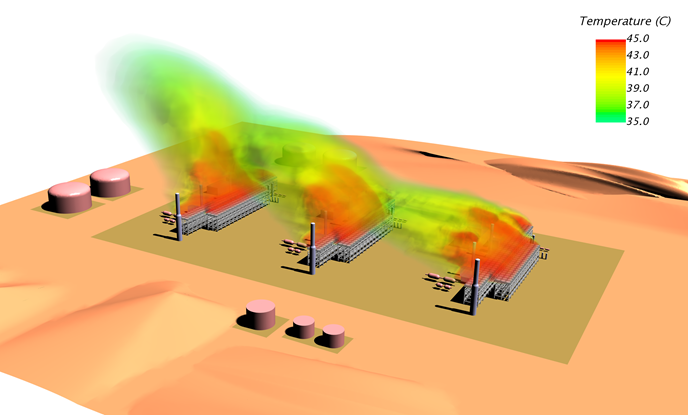

Hot Air Recirculation Analysis

Hot Air Recirculation (HAR) occurs in congested LNG plant where there are a number of Air Cooled Heat Exchangers (ACHEs), i.e., the hot air discharged from ACHEs is re-ingested through intakes of adjacent ACHEs. The HAR has potential detrimental effect on plant performance since it depends on the temperature of air supplied to the ACHEs. Thus, simulating the flow and temperature distribution of air around LNG plant, and assessment of intake temperature rises of ACHEs and are need.

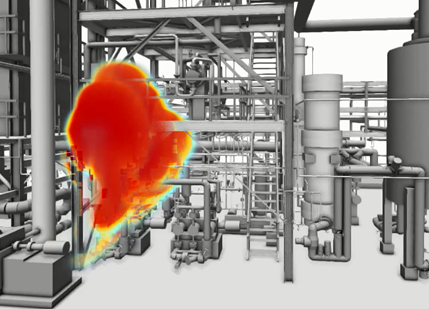

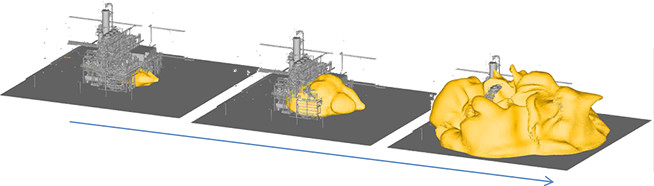

Explosion Simulation due to Flammable Fluid Leakage

Dispersion and explosion of flammable fluid are need to be simulated as a part of risk assessment.

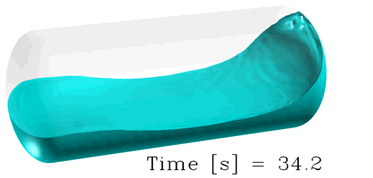

Sloshing evaluation technique

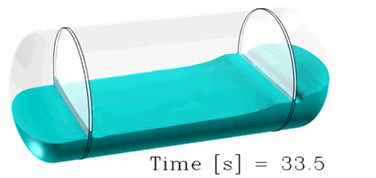

On floating oil and gas production platforms, sloshing is need to be considered for equipment containing a liquid with a free surface since it affects the efficiency of oil-gas separators. Computational Fluid Dynamics simulation is used to assess the sloshing and investigate effect of mitigation measures for that such as internal baffle.

Sloshing Simulation

Process Development

Reactor Scale-Up

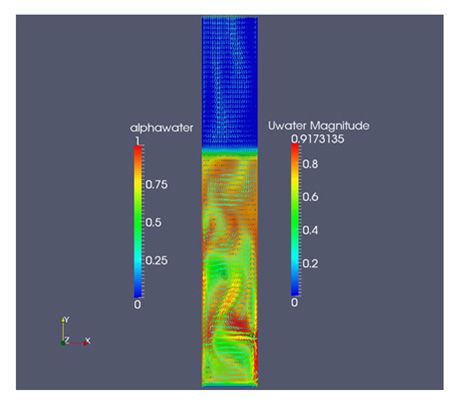

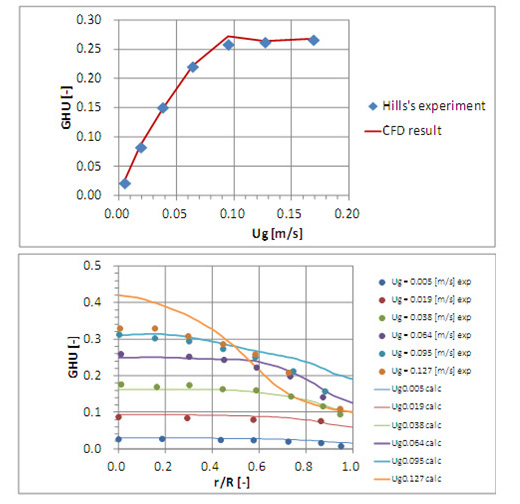

Computational Fluid Dynamics simulation is used to provide insight into scale-up of reactor. Combining results of CFD with process simulation will allow to assist complehensive design and development of new process. Following figure shows validation of simulation for bubble column reactor.

Bubble Column Simulation

Void fraction and velocity vector

Compasion with measurment

Stirred Tank Reactor Scale-Up

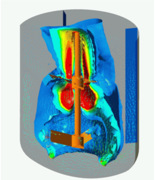

Stirred Tank Simulation

Following figure shows simulated flow pattern in stirred tank reactor.

Appilication for Equipment Diagnosis

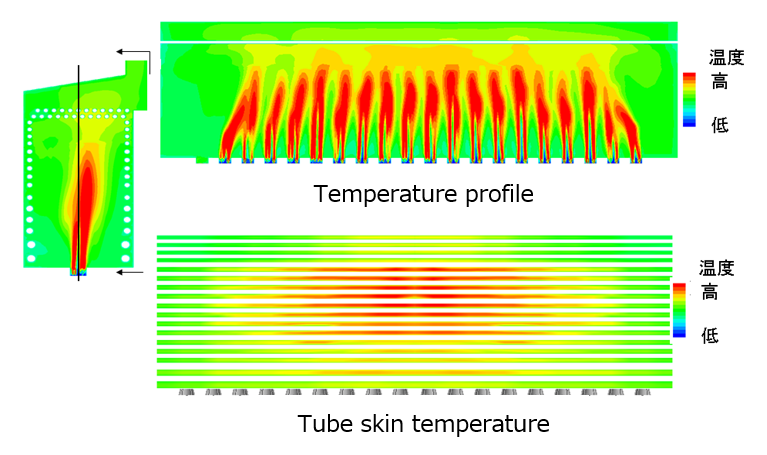

Fired Heater Diagnosis

Example of Furnace Diagnosis Program

Simulating heat and fluid flow in fired heater allow to assess temperature distribution in heater and skin temperature of heating tube which can be utilized to identify points to be monitore.

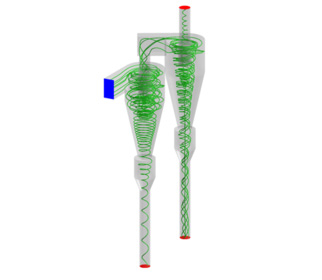

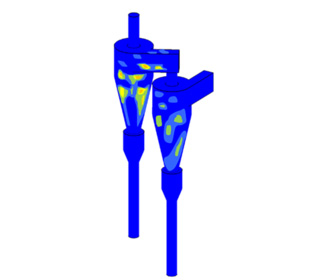

Erosion of Cyclone Separator

Particle behavior in cyclone separator is simulated to predict erosion. The results are utilized to study measures for life extension of cyclone.

Cyclone Simulation

Particle trajectory

Erosion profile

Capabilities

Computational Fluid Dynamics (CFD) simulation technology, which has advanced significantly along with improved computer performance, makes possible the observation of fluid dynamics using solutions to fluid dynamic equations and is commonly used to verify the design of important plant areas, analyze trouble in existing plants, and improve their performance.

Applicable range

- Hot Air Recirculation Analysis

- Dispersion study for flare and vent

- Heat and Fluid Dynamics in pipes and equipment such as drum, column, heat exchanger, fired heater and reactor.

- Risk assessment for flammable/toxic fluid leakage, despersion and explosion.