Metals and Materials

Contributing to the Stable Supply of Metals, Semiconductors and Advanced Materials from a Decarbonized Society and Economic Security Perspective

Initiatives to accelerate decarbonization are accelerating across industry, including transitioning from fossil fuels to energy sources with reduced environmental impact, such as renewable energy and electrification.

With exceptional conductivity compared to other metals, copper is used in equipment and infrastructure as a key electrification material, such as in electric vehicle motors, for electrodes and heat collectors in solar power generation and in underground and undersea cables for transmitting electricity generated from renewable energy to remote locations. The demand for copper is expected to increase in the future and ensuring a stable supply of copper, and other essential metal semiconductors and advanced materials, is a critical challenge.

Chiyoda's Track Record in the Field of Metals and Advanced Materials

Chiyoda's first mining, smelting and metal sector construction project was a copper smelter for PT. Smelting in Indonesia in 1996. This was the first copper smelting plant in Indonesia, for which we also conduct maintenance and inspection services.

We also secured an SX-EW project for Myanmar Ivanhoe Copper in Myanmar, thus gaining experience in both pyrometallurgy and hydrometallurgy.

Chiyoda has also successfully completed rare earth-related projects such as Titanium Sponge Plant, Nickel Plant, polycrystalline silicon plants, neodymium magnet production and lithium production studies in salt lakes.

Key Projects

Source :PT Smelting web page

(http://www.ptsmelting.com/)

Photo :Courtesy of Toho Titanium Co., Ltd.

Photo :Courtesy of Taganito HPAL Nickel Corporation

Photo :Courtesy of Advanced Metal Industries Cluster and Toho Titanium Metal Company Limited(ATTM)

Copper Smelting Project in Indonesia

Chiyoda completed the world’s largest single line capacity copper smelting plant for PT Freeport in Indonesia, a national strategic project in 2024 that is pursuing an economic security strategy by leveraging its extensive mineral resources. Chiyoda carries out maintenance and inspection services after plant completion.

The electrolytic copper produced at the plant will support domestic demand in Indonesia and the wider Asian region, including Japan, and Chiyoda continues to contribute to a decarbonized society through this project.

Future Business Development

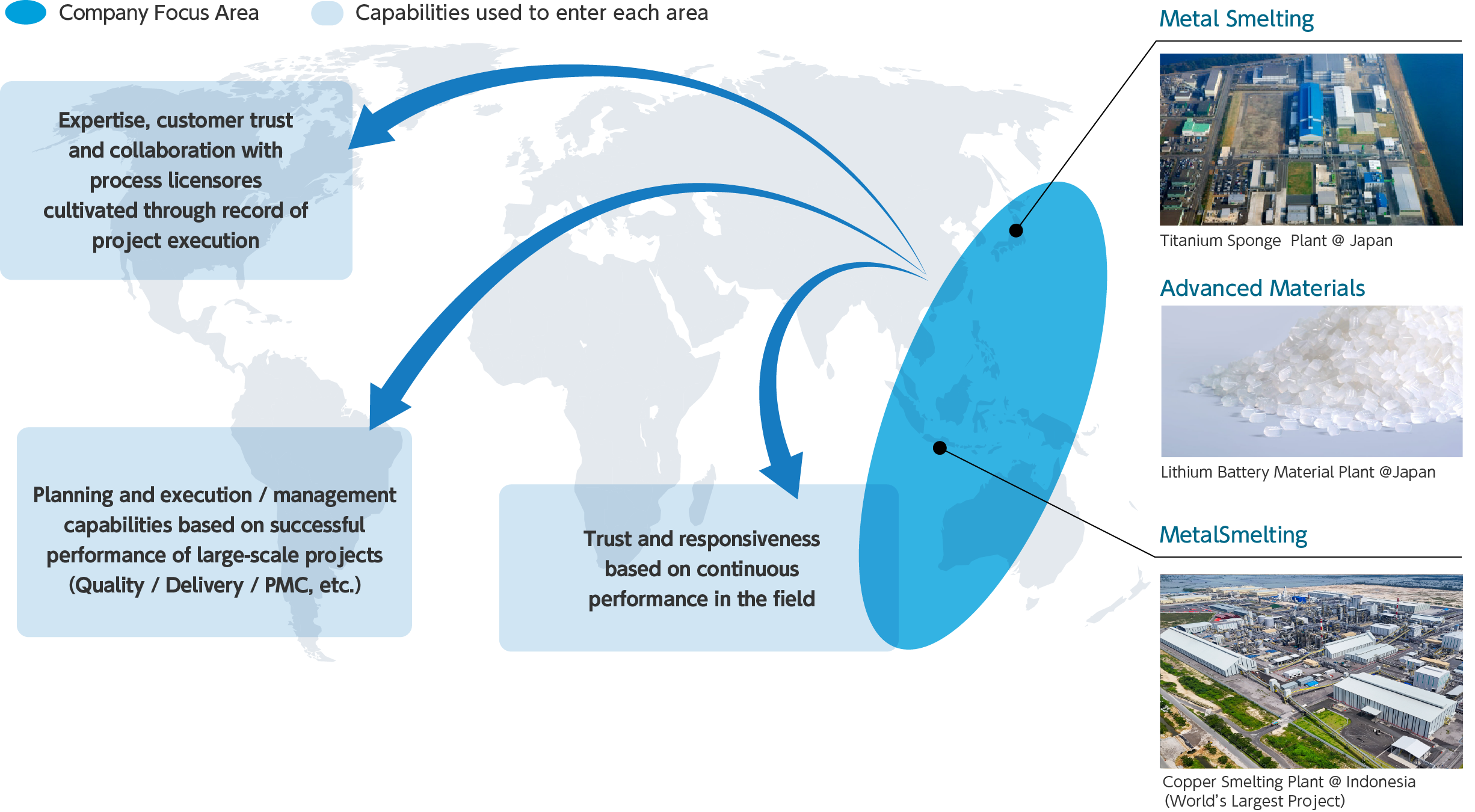

Engineering expertise, technological prowess, superior project execution capabilities, customer focus and fostering robust and long-lasting working relationships with customers through the construction of non-ferrous metal smelting plants, including copper smelting are Chiyoda’s competitive advantages.

We also leverage our strengths in non-ferrous metal smelting in upstream areas such as mining facilities and downstream areas including manufacturing, metal recycling and advanced materials.

As we expand our target regions beyond Japan and Asia to include Australia, North America and South America, we apply our strengths to develop our business into Project Management Consultant (PMC) and Operation & Maintenance (O&M), focusing on Engineering, Procurement, and Construction(EPC)projects.