Our Initiative to Safety

Since its foundation, 'Safety comes first' has been ensured in our group companies. We have further strengthened and foster awareness to safety culture by introducing 'C-safe' program since 2013.

Our Group's Entire Initiative

Through C-safe program in the office, Chiyoda group is implementing SQEI lectures and are offering various education, training, dialogue and training sessions continuously.

Education and Training

Hazard experience education using virtual reality (VR)

We introduced hazard experience education using virtual reality (VR) in our HQ in FY2017. Through this educational program possible hazards that workers face can be experienced artificially. This aims for deeper understanding of importance of on-site safety guidance by experiencing the fear of hazards.

Other education

We additionally conduct continuous education and training for workers who are assigned to construction site as follows.

- Pre-assignment onsite safety education

- Training sessions for beginners of safety health and environmental management (education for supervisors based on the article 60 of Industrial Safety and Health Act)

- Advanced training sessions of safety health and environmental management (education for general safety and health managers)

- Oygen deficiency special education

- Full harness special education etc.

We also continuously conduct one team conversation program "Better Together" where we discuss various topics related to safety and health in each department.

SQEI Lectures

We, across Chiyoda group hold SQEI lectures presided over by our CEO at least once a year. Different topic is picked up every time, aiming to raise awareness to safety and health of all our employees in the group.

1,028 employees attended the lecture in FY 2023.

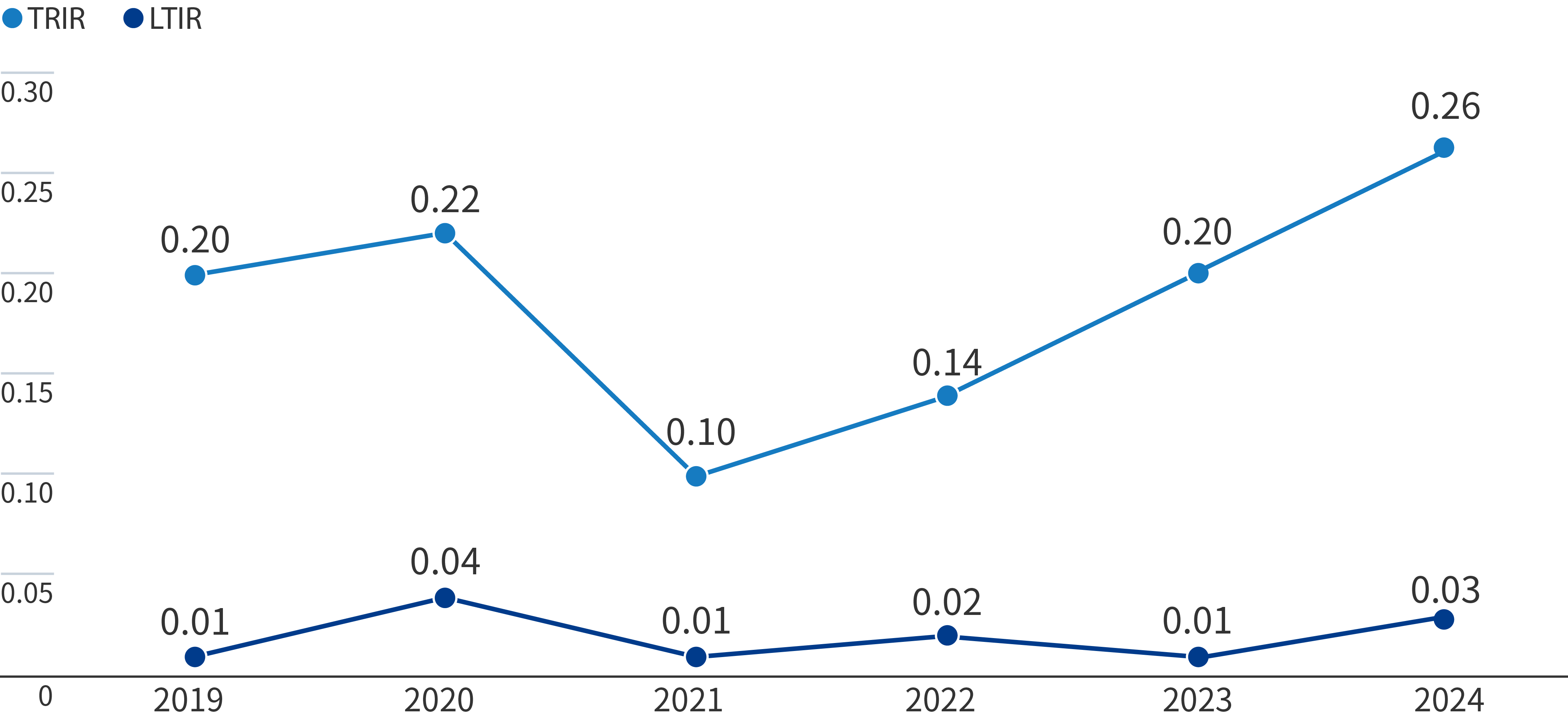

Safety performance

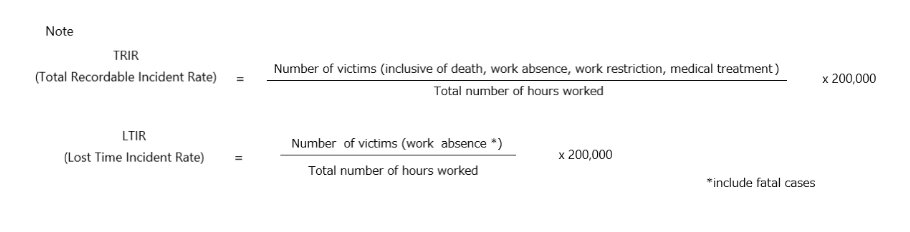

Following Occupational Health and Safety Management System, we set a 'company-wide HSE*1 goal' in each fiscal year and develop 'company-wide HSE program'. Based on this company-wide program, each section extends concrete activities of safety management. In FY2023, our company set a safety performance goal of industrial accident rate TRIR *2 which includes medical treatment and restriction of work(accidents not accompanied by lost workdays) to be below 0.5 (domestic) and below 0.15 (overseas)

- Health, Safety and Environment

- Total Recordable Incident Rate (Following OSHA, U.S.A. definition)

Overseas and Domestic onsite TRIR/LTIR

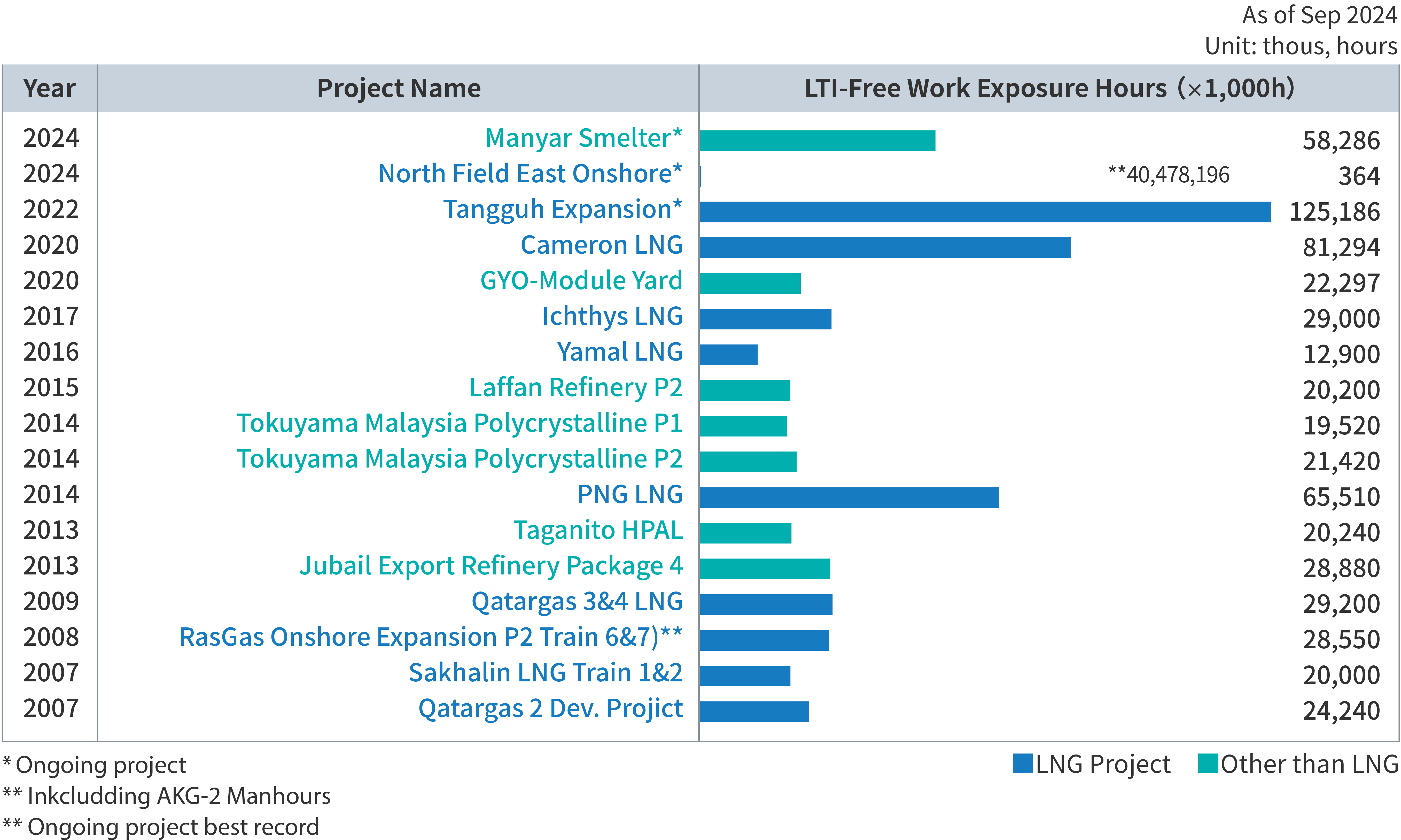

Our group's onsite safety records show accident-free and disaster-free continuous working hours reaching 60 to over 80 million hours in multiple overseas projects as seen in the chart below.

We will continue to strive for accident-free and disaster-free environment so that all our fellow workers can be back to their beloved family safe and sound.

Accident-free and disaster-free continuous working hours based on OSHA U.S.A definition