Hydrogen LOHC-MCH System

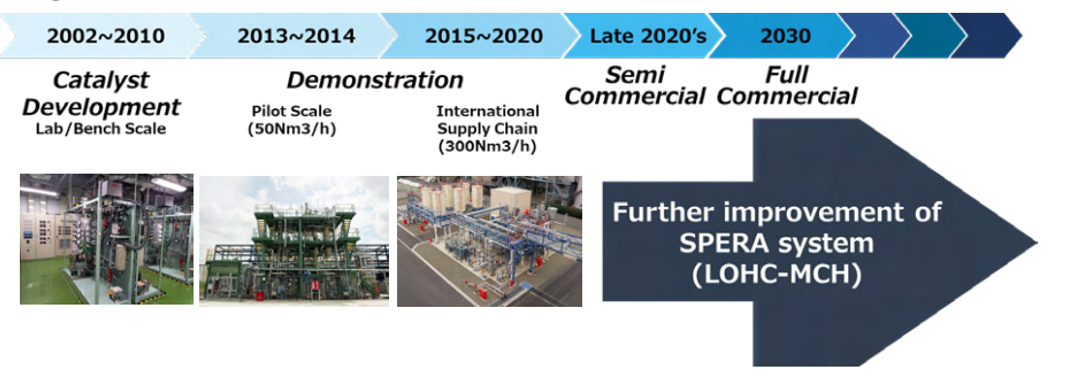

History of Hydrogen Technology Development

Chiyoda commenced research and development of hydrogenation catalysts in 2002, achieved success on a laboratory scale in 2011, conducted a pilot test to demonstrate the technology's effectiveness through 10,000 hours of continuous operation in 2014, successfully completed the world's first international hydrogen supply chain demonstration project in 2020 and continues reducing costs and improving efficiency through technological improvements towards commercialization.

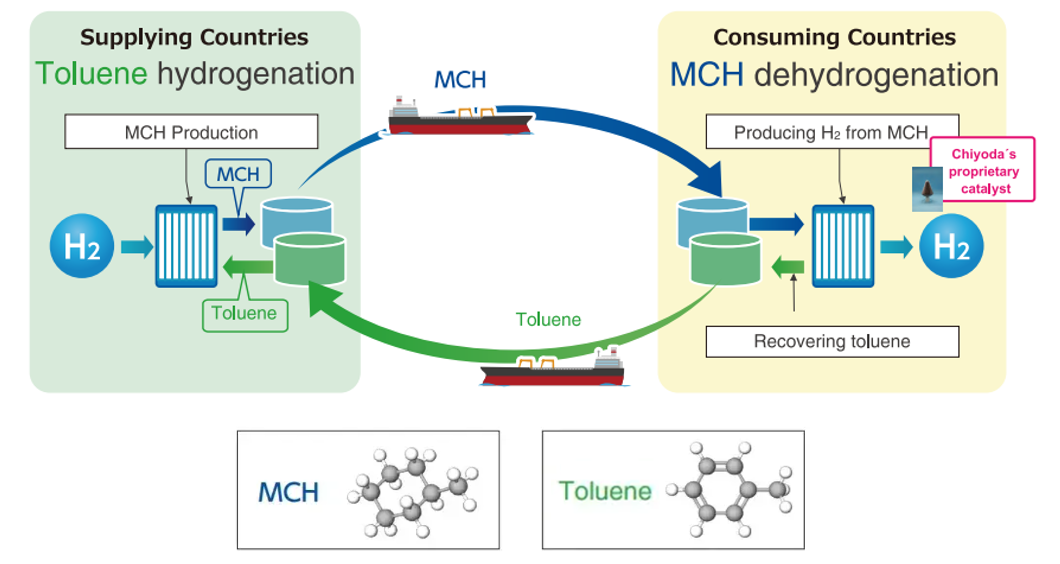

Hydrogen Supply Chain Circulation System

Chiyoda’s proprietary Liquid Organic Hydrogen Carrier (LOHC) technology uses methylcyclohexane (MCH), enabling the safe and efficient long-term storage of commercial quantities of hydrogen and transportation over long distances using existing infrastructure, such as oil storage tanks and conventional tankers, and current international laws, standards and regulations. As a liquid at ambient temperature and pressure and widely used in the manufacture of pharmaceuticals and as a solvent for correction fluids, MCH enables the efficient and safe storage and transportation of hydrogen because it contains over 530 times hydrogen per unit volume than hydrogen in its gaseous form.

Hydrogen is chemically combined with toluene through ‘hydrogenation’ in the hydrogen supply country to produce MCH for transportation using conventional tankers or other existing maritime method. In the demand country, Chiyoda's ‘in-house’ developed proprietary dehydrogenation catalyst is used to extract hydrogen from MCH through ‘dehydrogenation’ for distribution to end-users. The toluene recovered during dehydrogenation is transported back to the supply country, using identical return tankers or the same other method, and recycled as the raw material for further hydrogenation in a continuous ‘loop’.

Chiyoda has named the system ‘SPERA HydrogenTM’ (SPERA meaning ‘hope’ in Latin).

The SPERA Hydrogen system enables safe and efficient storage, transportation and distribution of hydrogen to consumers anywhere in the world.

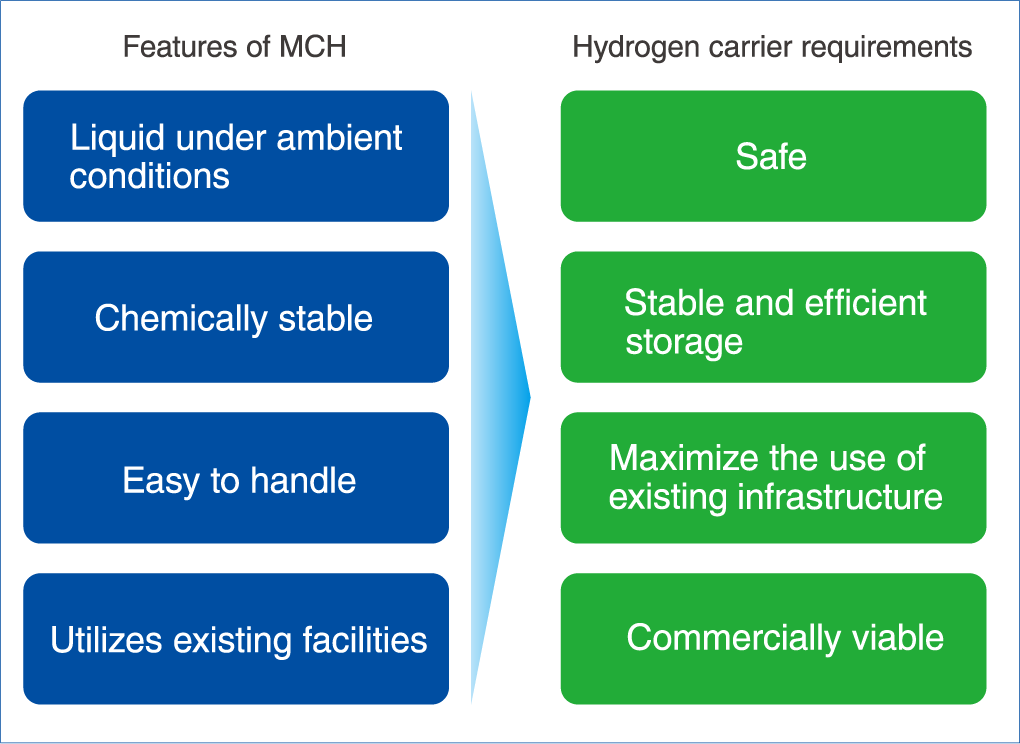

Advantages of MCH

The advantages of MCH as a cost effective and practical solution for a hydrogen society include:

- MCH is a liquid at ambient temperature and pressure .

- MCH is chemically stable.

- MCH is easy to handle and allows for efficient long-distance transportation and long-term storage of hydrogen.

- Existing storage and transportation infrastructure, such as redundant petroleum storage tanks and conventional chemical tankers can be utilized for transportation, minimizing initial investment costs.

Using our ‘in-house’ developed proprietary dehydrogenation catalyst, Chiyoda’s ‘SPERA Hydrogen’ LOHC-MCH technology is the ultimate hydrogen carrier system towards realizing a hydrogen society, enabling the safe and efficient long-term storage of commercial quantities of hydrogen, transportation over long distances to end-users across the globe.

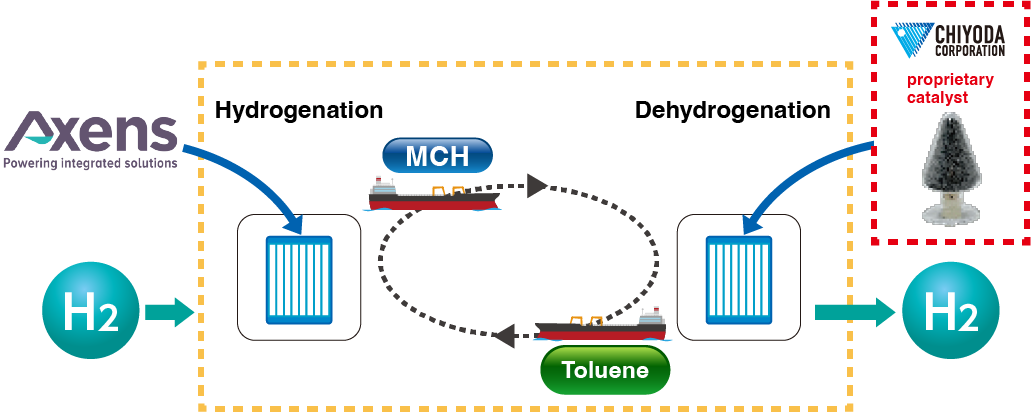

Commercial Cooperation with Axens on a Global Hydrogen Supply Chain

We have commenced a strategic commercial cooperation agreement with Axens, based in France and possessing toluene hydrogenation technology, enabling the production of high-purity methylcyclohexane (MCH) from toluene and hydrogen with optimized energy efficiency, for perfect synergy with Chiyoda’s MCH dehydrogenation technology that facilitates the production of hydrogen and toluene from MCH with high conversion rates and selectivity.

By offering the technologies and strengths of both companies in a one-stop solution, we aim to accelerate the development of global hydrogen supply chains using MCH as the Liquid Organic Hydrogen Carrier (LOHC).

Commercial Cooperation with Axens on a Global Hydrogen Supply Chain