e-fuel(Synthetic Fuels)

Solutions for the Social Implementation of Next-generation Fuels

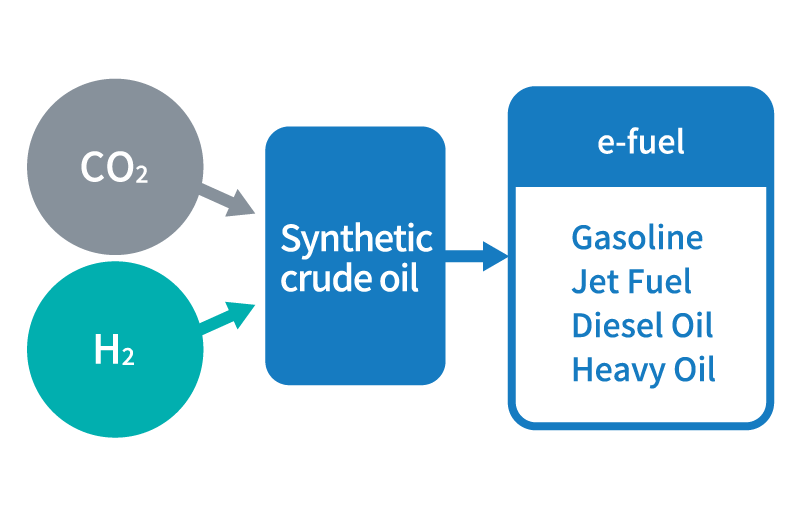

Synthetic fuel is artificially produced by synthesizing carbon dioxide (CO2) and hydrogen generated through the electrolysis of water using renewable energy sources. E-fuel has the following advantages and is expected to contribute towards carbon neutrality as a next-generation fuel by replacing existing fuels such as methane, gasoline, diesel and jet fuel.

- Although CO2 is emitted during combustion, e-fuel reduces overall CO2 emissions by over 70% by reusing the CO2 emitted from power plants, factories or existing in the atmosphere.

- The hydrogen used as a feedstock is produced through the electrolyser using renewable energy sources, resulting in no CO2 emissions during the manufacturing process.

- E-fuel does not contain sulfur or heavy metals compared to crude oil, reducing the risk of health-damaging pollutants such as SOx (sulfur oxides) and NOx (nitrogen oxides) in the exhaust gas.

- Existing infrastructure, such as petroleum and natural gas supply chains, can be used for distribution and sales.

Chiyoda continues contributing to the expansion of e-fuel by providing solutions that support its social implementation and participating in projects involving the construction of testing facilities.

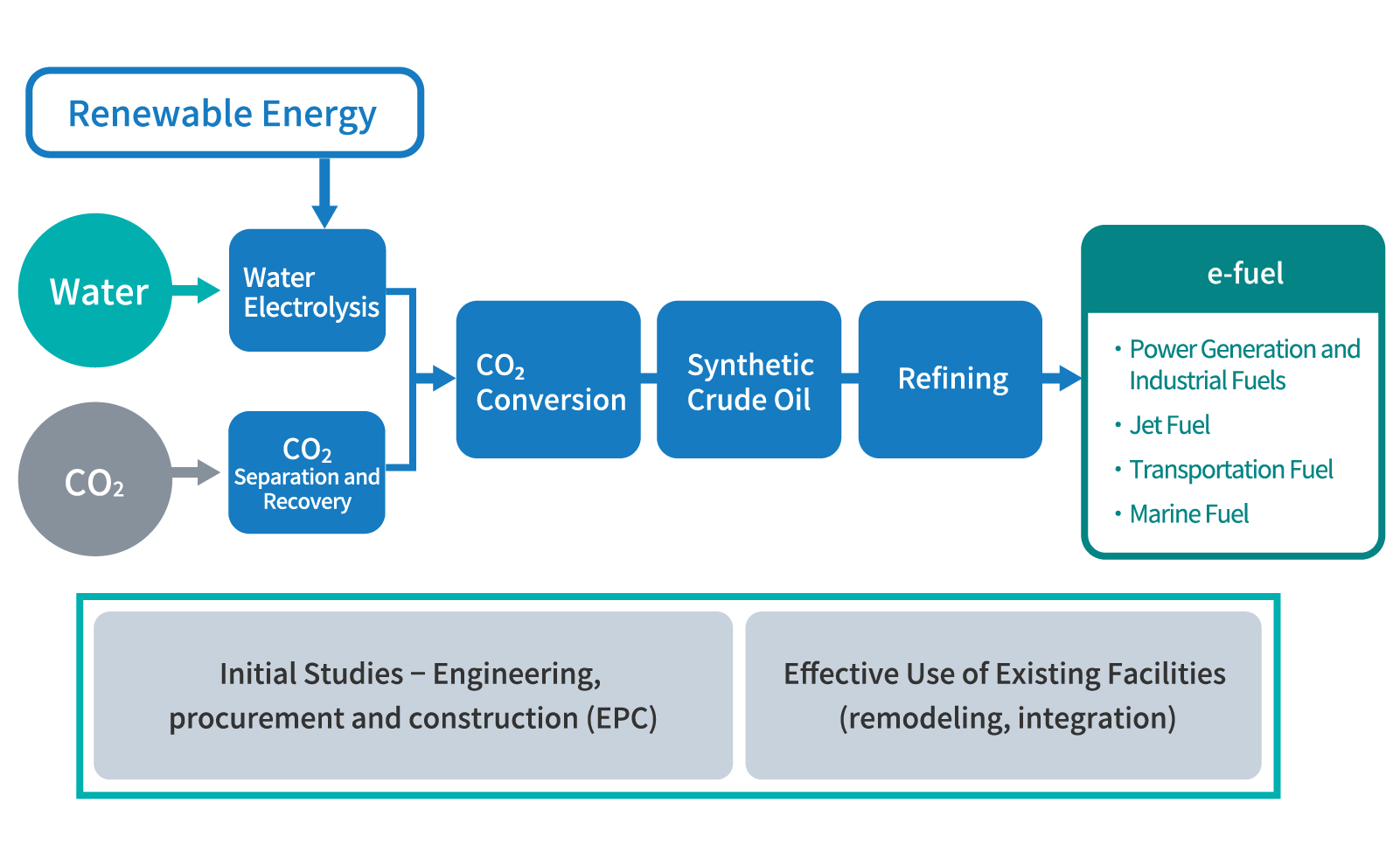

Chiyoda’s end-to-end solutions from hydrogen production to e-fuel manufacture.

Chiyoda offers end-to-end solutions to support e-fuel commercialization, from hydrogen production to fuel synthesis and purification, including initial feasibility studies, design, procurement, construction and integration of existing facilities for effective utilization. We provide tailored proposals, ranging from small to large-scale operations, that combine the most suitable and cost-effective technologies for our customers business strategy.

[Chiyoda Solutions]

Chiyoda completed a small-scale demonstration plant with a target production capacity of 1 barrel per day (B/D), as part of an ENEOS Corporation project and selected under the NEDO Green Innovation Fund, aiming to establish early-stage technology for the production of synthetic fuel using CO2 and hydrogen as feedstock. The purpose of the plant is to evaluate key technologies and demonstrate the consistent production of synthetic fuel, with a focus on improving the yield of liquid fuel to over 80% and reducing the cost of synthetic fuel for future social implementation. Through its execution, Chiyoda continues contributing to the social implementation of synthetic fuel production technology.