1B/D Synthetic Fuel Production Test Plant

- Client

- ENEOS Corporation

- Capacity

- 1 barrel per day (Small-scale Production Test Plant)

- Location

- ENEOSCorporation Central Technical Research Institute

- Scope of Work

- Engineering, Procurement and Construction (EPC)

- Year of completion

- 2024

Aiming for the early establishment of synthetic fuel production technology.

Synthetic Fuel - Next-Generation Energy Contributing to Carbon Neutrality

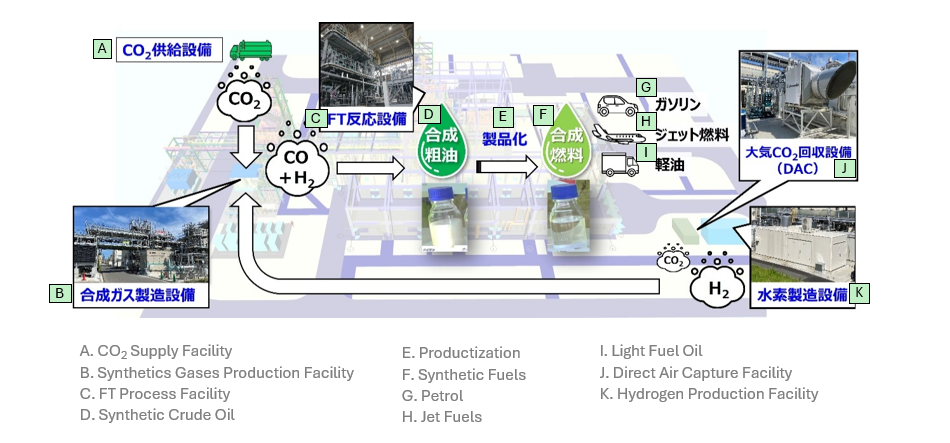

Synthetic fuel (e-fuel) is manufactured by synthesizing hydrogen (green hydrogen), derived from renewable energy, and CO2 emitted from power plants and factories. Since CO2 is used as a raw material for its manufacture, it is possible to offset the CO2 emissions during the manufacturing process, thereby reducing the CO2 emissions throughout the product lifecycle. Synthetic fuel has a high energy content per volume and weight and is composed of components similar to existing petroleum products, allowing for the utilization of existing infrastructure. Due to these advantages, it is gaining increasing attention as a next-generation energy source contributing to carbon neutrality.

Early Establishment of Manufacturing Processes

Chiyoda completed 1B/D (1 barrel per day) production test plant being conducted by ENEOS corporation, under a Green Innovation (GI) Fund program for the New Energy and Industrial Technology Development Organization (NEDO), aiming for the early establishment of a synthesis fuel production process using hydrogen and CO2 as raw materials.

The purpose of the test plant is to evaluate elemental technologies to improve the yield of liquid fuels to over 80%, and to demonstrate the integrated production of synthetic fuels with the aim of reducing costs.

Through the execution of this project, Chiyoda is contributing to the early social implementation of synthetic fuel manufacturing technology.

【Image of Overall Plant】

Courtesy of ENEOS Corporation(Translated by Chiyoda Corporation)