Supporting the transition to new energy sources on the path to a decarbonized society

– Firstly, can you please explain the basics of CCS?

CCS is a technology that separates and captures CO2 in flue gases from facilities such as industrial plants for storage deep underground. While renewable energy sources like solar power and clean energy which emit no CO2 during combustion, such as hydrogen and ammonia, are being developed to realize a decarbonized society, it is not feasible to immediately transition from traditional fossil fuels to these new energy sources. CCS serves as an effective measure for achieving carbon neutrality during the transitional period.

Research into CCS technology commenced decades ago but has only recently garnered significant public attention. Interest in Japan surged around 2020, when the government announced its goal of achieving carbon neutrality by 2050.

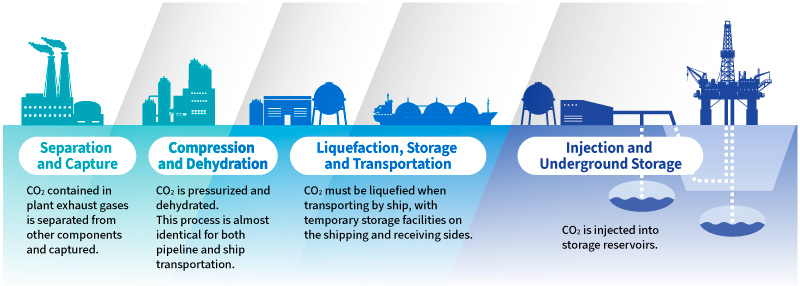

– Can you please walk us through the CCS value chain, from CO2 capture to underground storage?

The process begins with separating and capturing CO2, followed by compression and dehydration and ultimately injecting and storing it in underground reservoirs. If the distance to the storage site is short, CO2 can be transported in its gaseous phase through pipelines. For long-distance transport, the CO2 is liquefied to reduce its volume and shipped via vessels. In the case of transport by ship, temporary storage tanks for the liquefied CO2 are required.

Our extensive experience with liquefied natural gas (LNG) allows us to contribute significantly to the CO2 liquefaction segment of the value chain. Although LNG is utilized as a fuel and CO2 is stored underground, both processes share a common flow: liquefying gas for storage and transportation by ship. This parallel enables us to leverage our expertise from LNG and petrochemical industries in the CCS field.

CCS value chain

Acting as a ‘bridge’ between businesses to optimize the entire value chain

– What are the challenges in developing a CCS value chain?

Although technically feasible, a key challenge for widespread adoption of CCS is reducing costs, requiring close collaboration between businesses that make up the value chain.

A key focus area for reducing costs across the entire value chain is the specification of CO2. Downstream operators responsible for injecting and storing CO2 underground naturally want to minimize risks and prefer CO2 to be delivered with as many impurities removed as possible. Achieving purity increases the processing costs for upstream segments of the value chain, however thereby driving up overall costs.

– What are some effective solutions to this issue?

A coordinator who can facilitate collaboration between businesses from an overall optimization perspective is crucial. While each business involved in a project is a specialist in their respective field, not all are well-versed in the entire value chain. A coordinator who understands the expertise of each company and can ‘translate’ their needs and opinions into common and understandable terms is essential. Acting as a ‘bridge’ between businesses to optimize the entire value chain is a role that only an engineering company like ours, with extensive technical and commercial expertise, can effectively fulfill.

The ‘LCO2 Shipping Value Chain Standardization Council’, spearheaded by the Japan Organization for Metals and Energy Security (JOGMEC) and involving related organizations, is actively discussing the standardization of CO2 specifications as a major agenda item. I serve as a council committee member and provide recommendations from an engineering company perspective.

– It seems the role of an engineering company in connecting diverse technologies is vital to the success of projects.

Exactly. Chiyoda undertakes numerous projects as a partner and joint venture leader, as well as the Engineering, Procurement and Construction (EPC) contractor, working alongside global equipment manufacturers and construction companies. We successfully deliver plants while building collaborative relationships, even in environments where conflicts of interest arise or differences in business practices and cultures exist. Our experience is invaluable as we expand our CCS business.

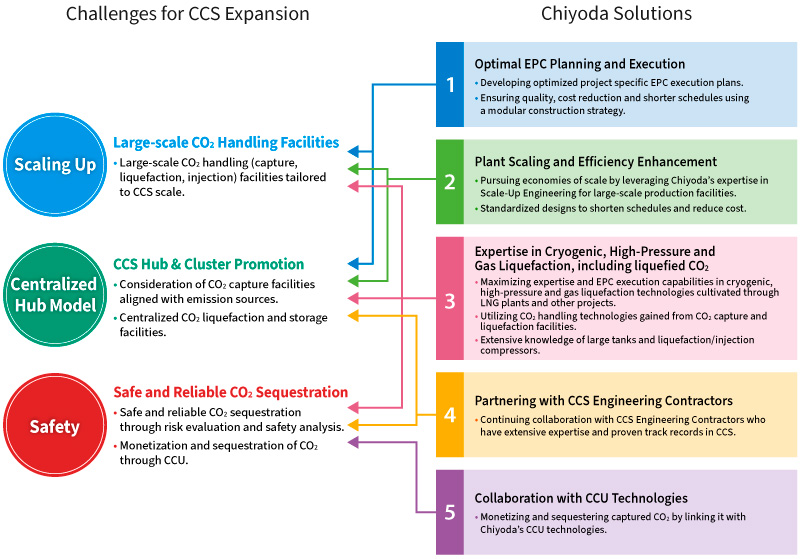

Providing the best solutions tailored to the environment

– What unique solutions does Chiyoda offer as an engineering company in the CCS business?

The Hub & Cluster framework, where flue gases captured from multiple emitters are collectively processed and transported, is considered effective in reducing costs across the entire value chain. The framework requires the ‘scaling up’ of facilities for CO2 separation and capture, liquefaction and storage. Our extensive experience in engineering, procurement and construction of large-scale plants, such as those in the oil, petrochemical and LNG sectors, enables us to offer tailored and effective proposals to meet these demands.

While it is generally expected that large-scale facilities require similar sized equipment and substantial volumes of materials, it is not always the most cost-efficient solution to prepare a single piece of equipment capable of handling the maximum expected capacity. When factoring in operating costs, dividing the workload across multiple pieces of equipment can often result in higher production efficiency.

Let’s consider CO2 capture equipment as an example. The volume of CO2 emissions from each business varies depending on the operating conditions of the emission source or fluctuations in power generation. A consistent amount of CO2 processing is not always required. Operating large-scale equipment during periods of low processing demand can be inefficient. Using a bus transportation analogy, there may be occasions when only 5 to 10 passengers require transport, even if a bus has a maximum capacity of 50 passengers. In such cases, owning five 10-passenger buses and operating only the required number would be less wasteful than operating a single 50-passenger bus on each occasion. Conversely however, purchasing one 50-passenger bus might be cheaper than buying five 10-passenger buses. The parking space required could also pose a challenge, as there may not be enough room to accommodate five smaller buses.

When it comes to plant design, determining the best solution requires a comprehensive approach tailored to the specific operational environment of the business. Our extensive experience of successfully delivering a wide range of domestic and international projects enables us to effectively manage all aspects, from planning to engineering, construction and operation, under diverse conditions.

Our strength lies in identifying perspectives or challenges that even the business operator may not have identified and working collaboratively to resolve them, ensuring an optimized overall solution. Our established relationships with equipment and material manufacturers and construction companies, combined with our expertise, enable us to deliver precise and practical proposals.

– What are the other areas where Chiyoda’s strengths stand out?

Safety is key for emitters and is an area where our expertise, developed through the EPC of plants across the globe, is invaluable, enabling us to conduct stringent and comprehensive risk assessments and safety analyses and incorporate the results into our designs to ensure peak safety levels.

For example, in CCS facilities, there is a potential risk that CO2 released into the atmosphere during emergency depressurization of a plant could cool down, forming dry ice and obstructing the piping pathways. We continuously anticipate such risk and leverage our expertise to propose designs that provide operators with peace of mind and ensure safe, reliable operations.

We are also fostering partnerships with professionals across fields in the CCS value chain to strengthen our contribution. In 2024, we signed a comprehensive license agreement for CO2 capture technology with Mitsubishi Heavy Industries Ltd., a global market leader in CO2 separation and capture technology with nearly 30 years’ experience, forming a partnership of industry leaders working together in the CCS sector. We are also collaborating with Nippon Yusen Kabushiki Kaisha (NYK Line), exploring methods for transporting liquefied CO2 within the CCS value chain and have partnered with Pace CCS, a UK-based leader in the CCS field with an extensive global track record. These partnerships with prominent domestic and international players enable us to drive innovation and leadership across the CCS industry.

Chiyoda's CCS Business Overview

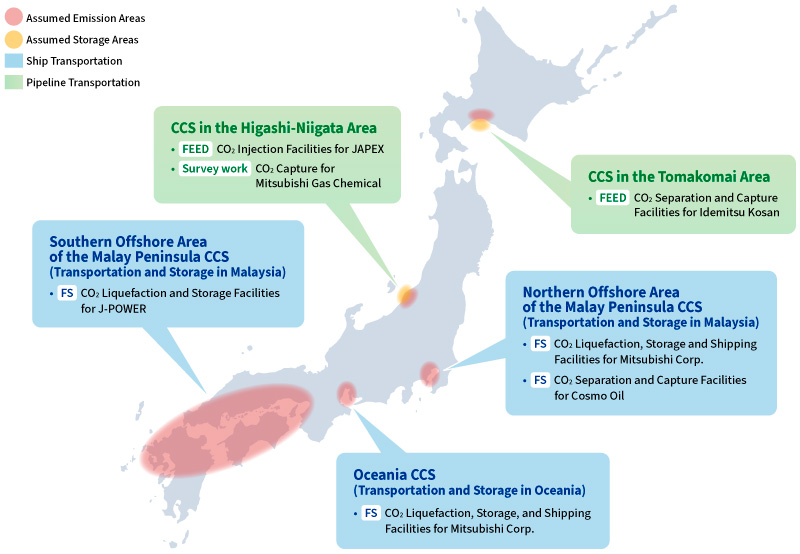

Advanced domestic CCS projects to accelerate social implementation

– The Japanese government is also accelerating CCS-related initiatives. Can you please elaborate on recent developments and Chiyoda’s involvement?

The Japanese government has established an ambitious milestone of achieving a 46% reduction in greenhouse gas emissions by FY2030 (compared to FY2013), as part of its broader goal of reaching carbon neutrality by 2050. A key initiative of utilizing subsidies to promote CCS model projects was launched in FY2023 to support this milestone, aiming to commence CO2 storage by FY2030. There are currently nine projects designated as Advanced CCS Projects by JOGMEC.

Chiyoda is proud to play a significant role in these initiatives, being involved in five of the nine projects, covering seven individual cases. No other company is involved in such a broad range of activities throughout the CCS value chain.

– Chiyoda handles tasks like FS※1 and FEED※2 in Advanced CCS Projects by JOGMEC. What role do these tasks play?

In large-scale projects such as LNG plant construction where investment amounts are substantial, even minor unforeseen deviations can result in significant losses. Comprehensive Feasibility Studies (FS) and Front End Engineering Design (FEED) prior to the EPC phase mitigate such risk. CCS is a relatively nascent global field with limited precedent projects. There are therefore significant uncertainties during the planning stage and thorough FS and FEED execution is essential.

- Feasibility Study:Examination of project feasibility

- Front End Engineering Design:Addressing technical challenges and estimating preliminary costs through basic design work.

Chiyoda’s role in Advanced CCS Projects

Press Release

Chiyoda Corporation Awarded Study of CO2 Liquefaction and Storage by J-POWER

Chiyoda Awarded the Study for CCUS Hubs and Clusters Concept in Niigata by MGC

– Our significant role in government CCS model projects reflects the trust and expectations placed in us by partner organizations. What is the reason for this?

Firstly, our extensive experience in consistently managing EPC projects enables us to manage a project in its entirety and make optimal decisions. This holistic capability has been instrumental in earning the confidence of partners.

Secondly, on the technical front, we have a proven track record in CO2 separation and capture, particularly through our work in LNG plant construction. Natural gas extracted from gas fields often contains acidic gases like CO2, which must be removed and treated and we have designed and constructed numerous facilities for this. We have also incorporated advanced technologies in the construction of LNG plants in Qatar and Texas in the USA to deliver more environmentally friendly LNG by reducing CO2 emissions and electrified plants to minimize environmental impact. This ‘Cleaner LNG’ approach has been enthusiastically received in the industry.

Our expertise and experience is a major factor in advancing CCS initiatives and a key reason why we continue to exceed business partner expectations.

–Please also tell us about Chiyoda’s initiatives overseas.

Our solid track record overseas is steadily growing. A recent key initiative is securing an FS project from a major Australian oil and gas development company in 2025, involving the construction of a CCS value chain.

Aligning with business aspirations and resolving challenges with innovative proposals

– Our experience accumulated over many years is a foundation for success in the new field of CCS. Can you please share your thoughts on leading this business?

I was originally a process design engineer, responsible for the plant configuration. I am now engaged with businesses in a technical sales role as a General Manager and cherish the ‘weight’ of our company's purpose: 'Enriching Society through Engineering Value’. As an engineering company, our ability to present optimal solutions tailored to meet the diverse needs of businesses and realize their aspirations is our greatest strength and a source of significant fulfillment for me as an engineer.

Our goal is to transform business needs into concrete proposals and to support businesses in realizing their aspirations. I take pride in the fact that this diligent effort is the driving force behind our position as a leader in the CCS business in Japan. Despite the challenges and significant costs associated with decarbonization initiatives, which often render it difficult to generate profits, CCS is essential to achieving carbon neutrality. I am committed to breaking through these barriers through the power of engineering.