装飾1

装飾2

装飾3

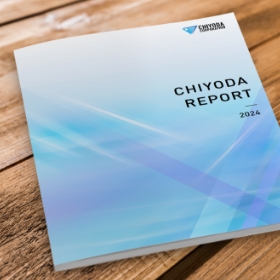

Enriching Society

through Engineering

Value

News

Latest News-

Information

Digital signage advertising will be launched at Yokohama Landmark Tower [July 14 - August 10]

-

Press Release

Chiyoda Corporation and Ekwil Awarded Feasibility Study of Floating Offshore Wind Turbine Project in Japan

-

Press Release

Development of Large-scale Production Technology for Useful Proteins Using Plants

Launch of a 'Plant Biofoundry' - a Demonstration Platform in the Field of Bio-manufacturing -

Press Release

Announcement of Wage Increase for Fiscal Year 2025

-

Information

Encouragement to take Annual Paid Leave on July 18, 2025

装飾1

Engineering

New Social Value

New Social Value

FUTURE

装飾2

装飾1

Addressing Diverse

Social Challenges

Social Challenges

BUSINESS

装飾2

装飾1

Leveraging Our

Strengths

Strengths

ADVANTAGE

装飾2

装飾1

Together with

Society

Society

装飾2