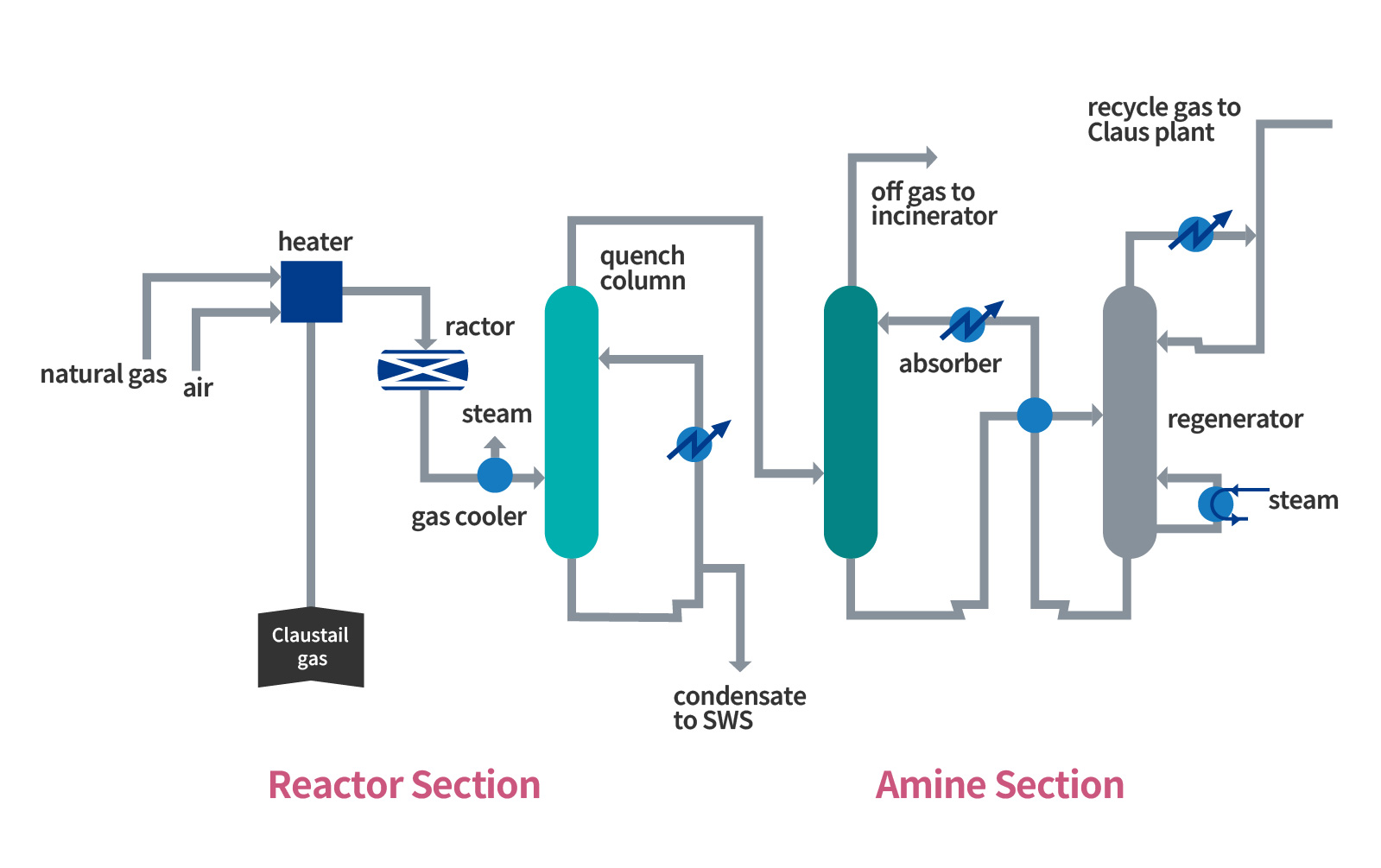

Tail Gas Treatment (TGT)

The tail gas treatment process reduces sulfur vapor and SO2 contained in the tail gas from the Claus process to H2S, absorbs it in the absorbing solution (amine) and returns it to the Claus process, thereby achieving a high rate of sulfur recovery. Shell’s SCOT process is a representative TGT process, comprising a section where the sulfur content is reduced to H2S, and a section where H2S is absorbed by amine. Depending on the feed gas composition, it can yield over 99.9% sulfur recovery rate in ordinary oil refining plants and over 99.2% sulfur recovery in gas or LNG plants.

Capabilities

- With our unsurpassed experience, Chiyoda is an authorized licensor of the Shell SCOT process.

- The SCOT process is an established technology and over 300 units are operating efficiently worldwide.

- A recent technological innovation is enhancement of the hydrogenation catalyst reducing mercaptan, COS and other organosulfurs in the tail gas of the Claus process to H2S in a lower reaction temperature to enhance energy saving efficiency and simplify the equipment. The use of amine, which features high H2S selectivity, achieves over 99.9% sulfur recovery of sulfurs in gas and LNG plants. These are examples of Chiyoda’s SCOT process design and construction expertise and we have designed and constructed processes similar to the SCOT process based on client requirements.

- Exhaust gas is treated as lower than approximately 250ppmv H2S composition gas. To provide Incinerator and Fuel Gas Desulfurization facility, the design considered in the environment is possible.

- If a higher sulfur recovery rate is required, it is possible to achieve a recovery rate of 99.9% by adopting Hindered Amines with high H2S selectivity, such as ExxonMobil/BASF's Flexsorb SE+.

Applicable Range

The SCOT process can utilize tail gases containing sulfur compounds such as SO2.