Sulfur Recovery Unit (SRU)

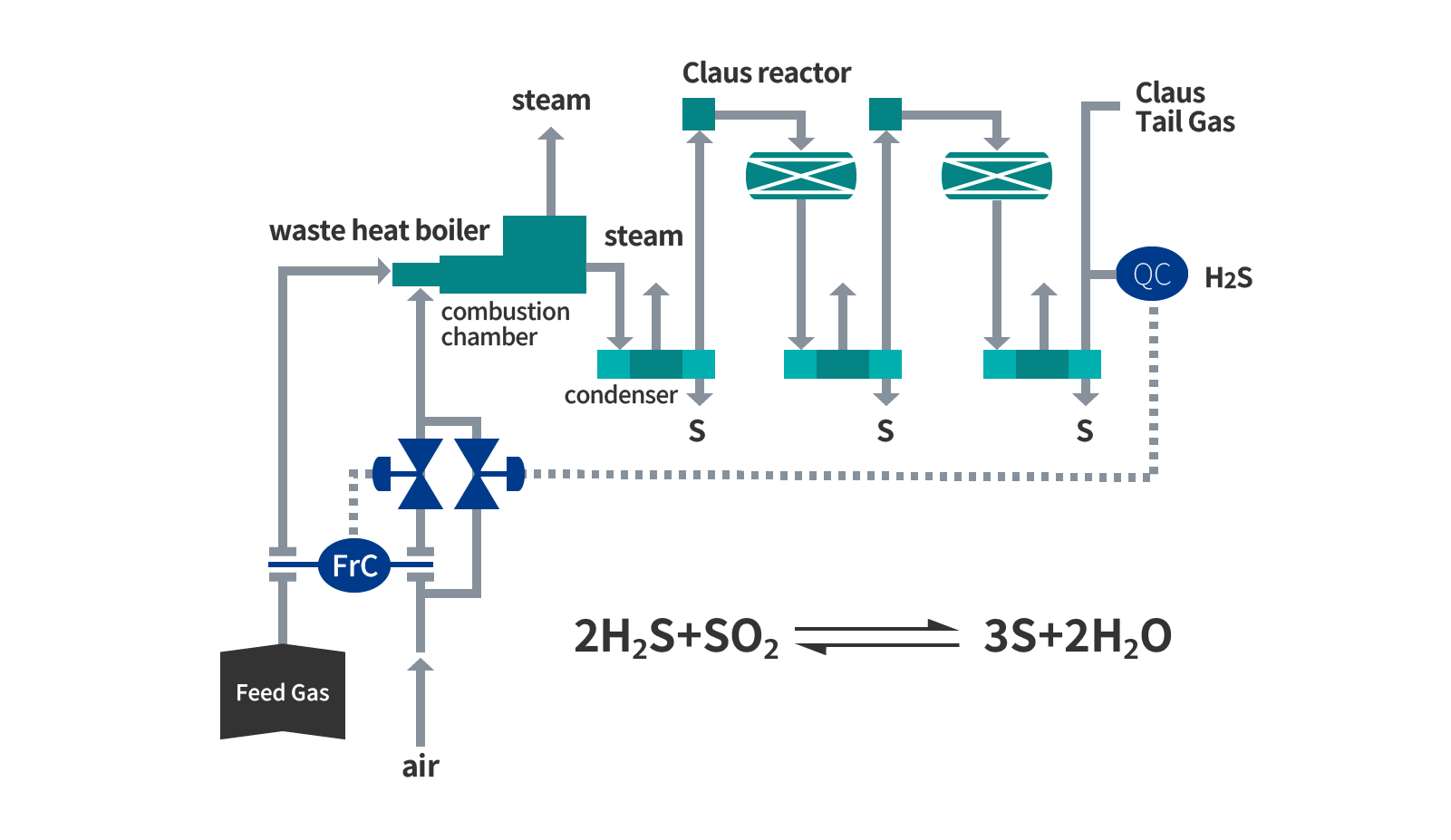

Hydrogen sulfide (H2S) is removed in the AGR process and sent to the sulfur recovery unit (SRU) as acid gas, to be recovered as elemental sulfur through Claus reaction as shown below. The reaction occurs in two stages: the flame reaction stage and the catalytic reaction stage. The former consists of a high-performance burner, mixing chamber and heat removing boiler and the latter has two to three reactor stages. The sulfur recovery rate of the Claus process is approximately 95 to 97%. The tail gas containing unrecovered sulfur is fed to the tail gas treating unit (TGT) and the recovered sulfur is stored in a sulfur pit and shipped as a product after degassing to remove H2S.

It is essential for the Claus process that appropriate burners be selected and the correct catalysts are used to ensure a high recovery rate and long service life. The Claus process is an equilibrium process and a modified version with direct oxidation catalysts stored in the final stage is called Superclaus. Since this improved process does not depend on Claus equilibrium, it can attain a 99% recovery ratio without TGT (Licensor: Worley Comprimo).

Chiyoda is the sole engineering contractor capable of managing the Superclaus process due to our exclusive contract with Worley Comprimo in the domestic market.

Capabilities

- Chiyoda conducts our own design, including burner and catalyst selection and the design of mixing chambers etc.

- A 99.9% recovery rate can be achieved using the Claus and TGT processes (a SUPERCLAUS/TGT combination is not possible).

Applicable Range

Acid gases with a hydrogen sulfide (H2S) content of over 50% are suitable for the recovery of sulfur in the Claus process.

- Where the ratio of H2S to CO2 in the acid gas is low and the concentration of H2S falls below 50%, the Acid Gas Enrichment (AGE) process, using an amine solution, is applied to the acid gas from the AGR process to increase the H2S concentration. The AGE process uses a similar amine solution as AGR, but by optimizing the type and concentration of amine and the contact time between amine and gas, enhances the selective absorption of H2S and concentrates H2S. As an example, Flexsorb SE+ by ExxonMobil/BASF, which has excellent selectivity for H2S, has been adopted in amine solutions and AGE has been installed in LNG plants in Qatar. Chiyoda’s track record with AGE is unique.