Acid Gas Removal(AGR)

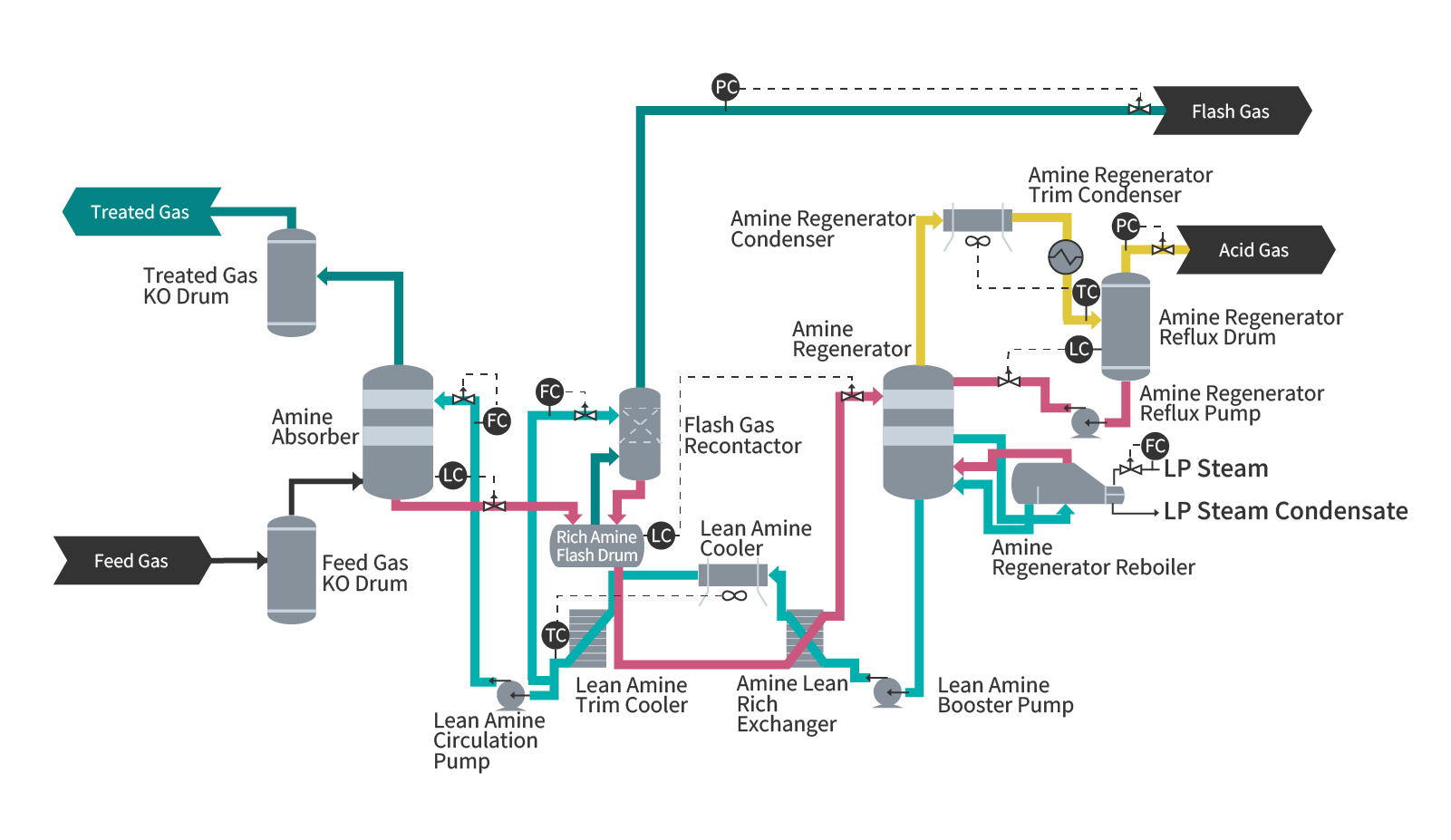

The AGR process removes H2S, CO2 and organic sulfurs (such as mercaptan and COS) in the raw feed gas to comply with LNG liquefaction process or sales standards. An amine countercurrent contacts the source gas inside an absorber column and the acid gases are absorbed by the amine for treatment. This is a ‘wet’ process and dehydration by molecular sieve is required at a later stage. Some processes cannot remove organic sulfurs and an additional molecular sieve bed may be required to perform that function.

Capabilities

- As an authorized licensor for the Sulfinol and ADIP processes of Shell Global Solutions International, Chiyoda has designed and installed many Shell processes.

- In the new Shell AGR process, Sulfinol-X can remove acid gas and organic sulfurs, required for gas processing, in a single absorption column, thereby eliminating the need for organic sulfur removal at a later stage. By coupling the use of chemical and physical absorbing agents with a redesign of the composition and mixture arrangement, the new process solves the problem of frequent co-absorption of hydrocarbons, the cause of previous Sulfinol-D problems.

- Chiyoda’s expertise and experience also encompasses other AGR processes such as BASF, UOP and Axens and can extend to any type of AGR process.

The main components of LNG feed gas are methane (CH4), ethane (C2H6) and propane (C3H8) with 0 ~ 15% H2S and 0~ 10% CO2 and, in some cases, organic sulfur (Mercaptanes etc). Chiyoda manages different types of feed gas through the selection of a suitable amine.