Refineries

With an extensive domestic and international track record of delivering ‘best-in-class’ facilities to our customers, including oil refining facilities, secondary processing facilities, lubricant manufacturing equipment, oil storage bases and related utility facilities, oil is Chiyoda’s traditional industry. We collaborate with customers through the entire project lifecycle, from the early planning stage through basic design, detailed design, procurement and construction. Our ‘one-stop service’ portfolio also includes supporting customers through the operation and maintenance of facilities to maximize the return on their investment.

Despite the accelerating global drive towards renewable energy, oil continues to be an indispensable source of energy for the global economy and Chiyoda are committed to delivering world-class facilities to our customers.

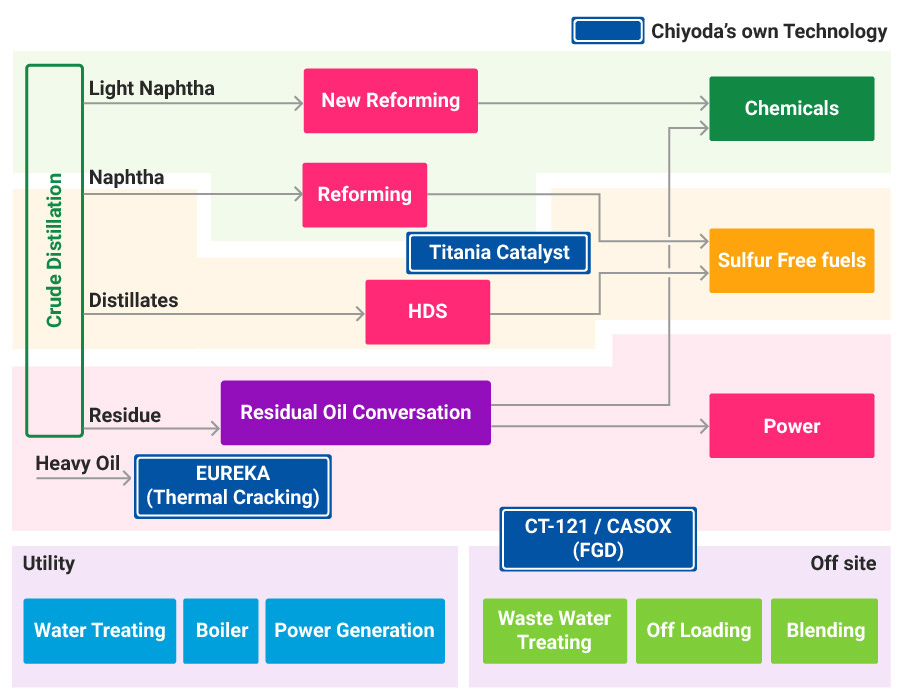

Key Technology

A. Environmental Regulation

- Gasoline sulfur free process

-Reduces the sulfur content in FCC gasoline - Ultra-low desulfurization process for gas oil

-Reduces the sulfur content in gas oil to below environmental standard limits.

B. Residue upgrading

- Thermal cracking process for heavy oil

-Coker process

-EUREKA® process - Residuum oil supercritical extraction (ROSETM)

-Separation of asphaltenes from heavy oil using supercritical solvents - • Residue HDS process

-Our experience of Residue-HDS includes over 60% of the domestic market and 30% of the world market

C. Chemical Oriented Refinery

- BTX process

- Para-xylene complex

- Petrochemical FCC