Advanced Design through Analysis Technology

Dynamic Simulation

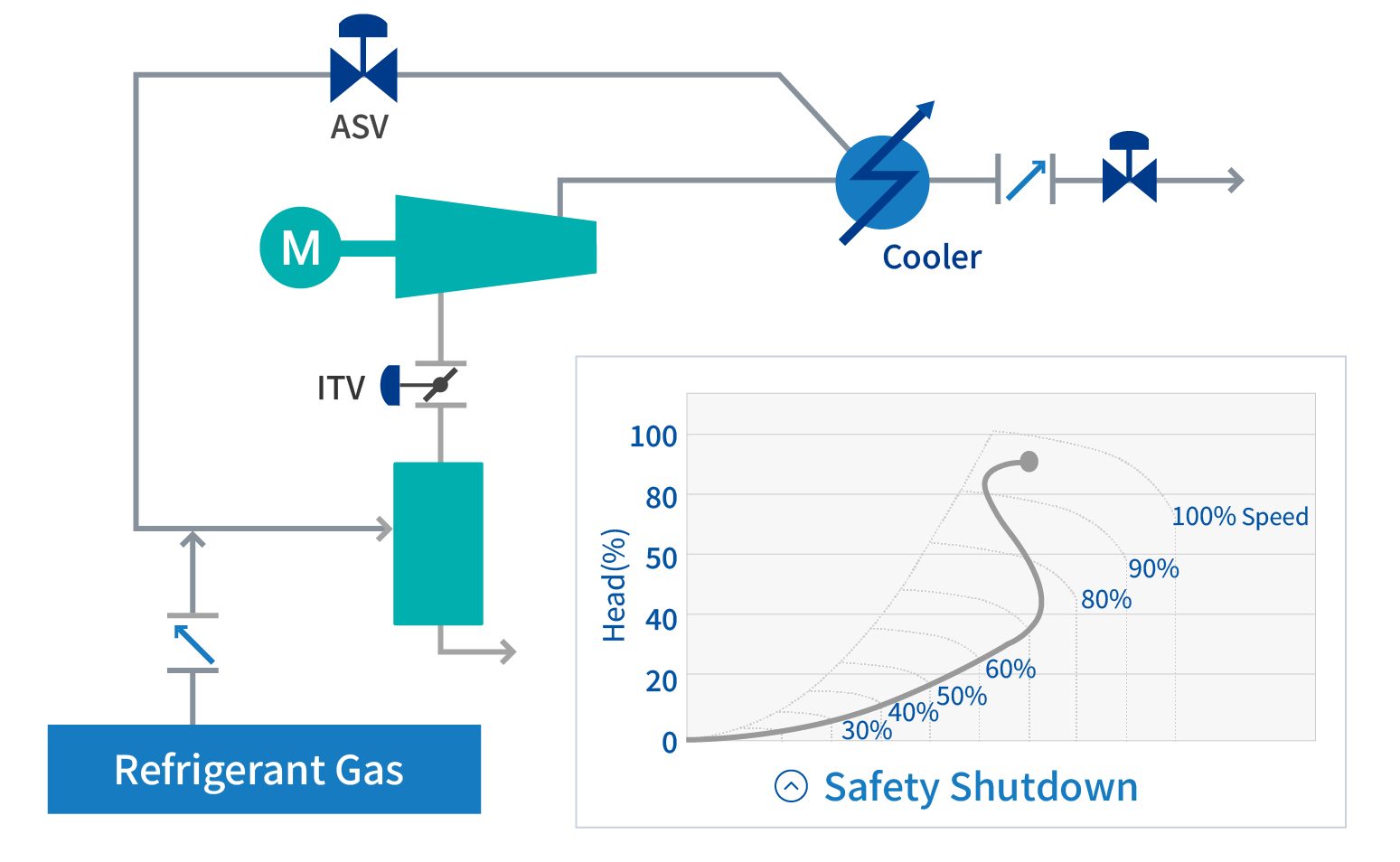

Dynamic simulations for plant systems, including refrigeration compressors, are used to understand dynamic behavior, confirm equipment design validity and ensure system safety measures during plant start-up or shutdown, by constructing detailed simulation models. Dynamic simulations are also used to understand key system behavior.

Computational Fluid Dynamics (CFD) Analysis

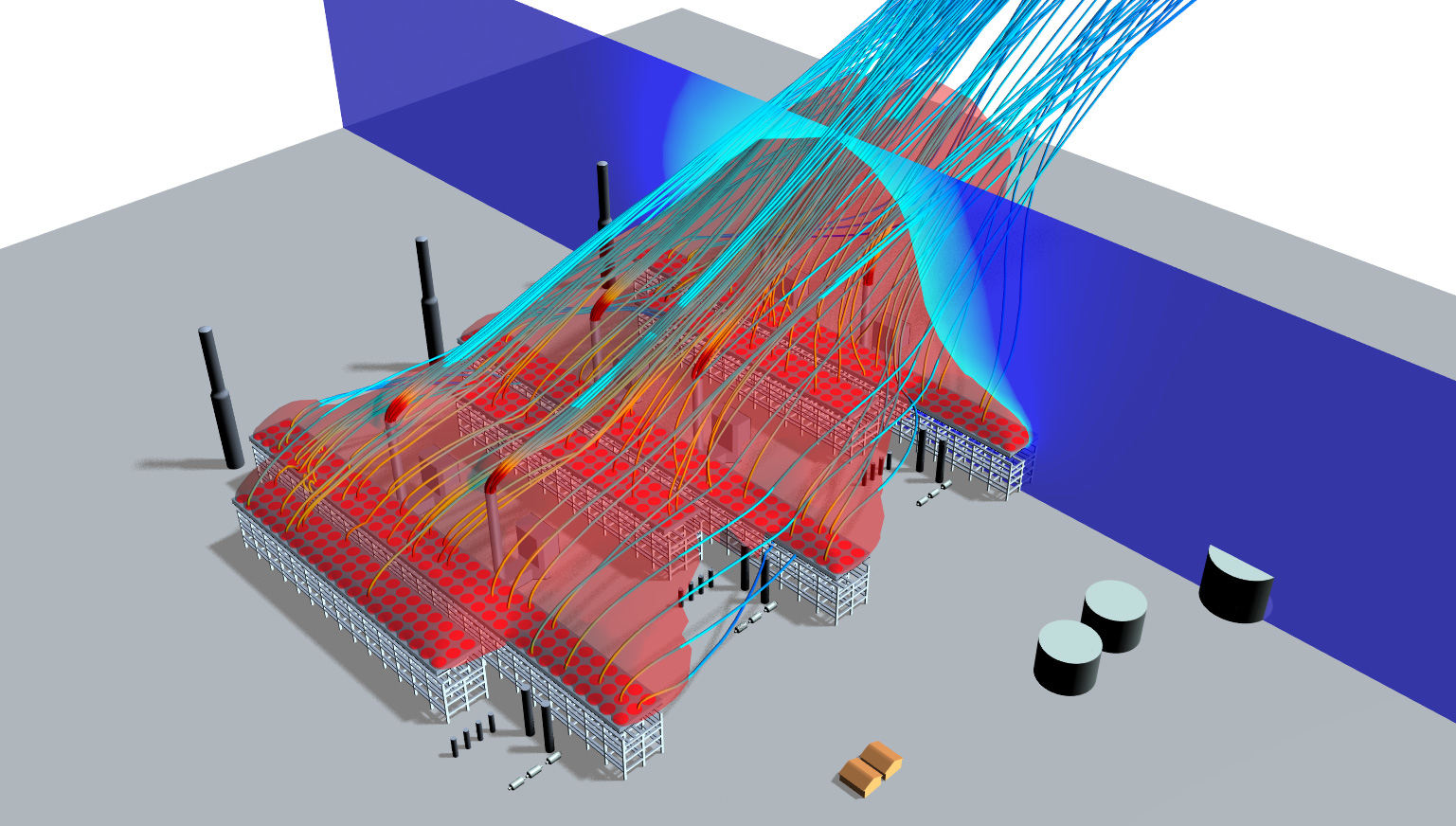

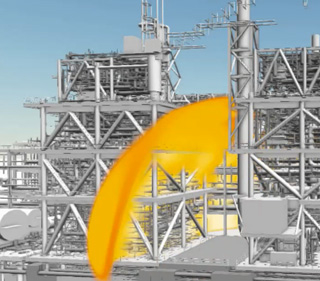

CFD analysis is performed to evaluate equipment integrity and performance in LNG plants. Chiyoda ensures safe and efficient equipment design by visualizing complex flow fields and devising improvement plans. For example, when using an air-cooled heat exchanger, Chiyoda incorporates optimal equipment placement and measures to ensure that the performance of equipment and LNG production are not compromised by heat dissipation and airflow from surrounding devices.

CFD analysis is applied not only to simple heat and fluid dynamics analysis but also to the analysis of complex phenomena, such as multiphase flows, combustion, chemical reactions and agitation within tanks. By utilizing CFD analysis, Chiyoda conducts high-quality comprehensive technical studies and provides solutions for equipment design and development, improving plant efficiency and reducing environmental impacts.

CFD Simulation for Thermal Fluid Dispersion around Air Fin Cooler (Hot Air Recirculation Analysis)

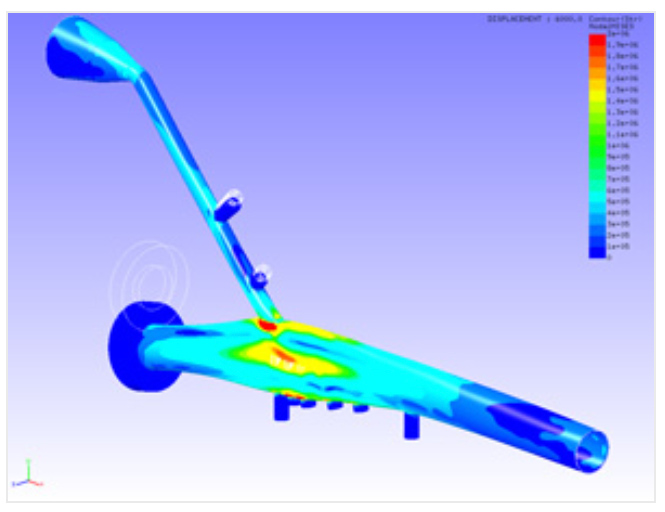

Structural Analysis

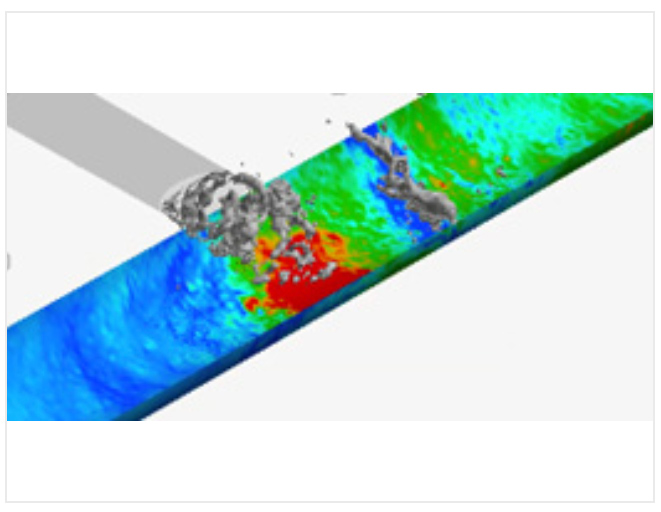

Chiyoda conducts structural integrity assessments (predicting stress and deformation) for equipment, piping and supporting structure. Vibration assessments, such as Flow Induced Vibration (FIV) and Acoustically Induced Vibration (AIV), is also performed for piping and equipment. As a leading LNG plant engineering company, Chiyoda contributes to the revision of international standards, based on our uniquely developed FIV/AIV evaluation technology, for piping integrity assessments during emergency depressurization, resulting in safer and more economical plants.

Fluid-Structural Interaction Analysis for Flow Induced Vibration

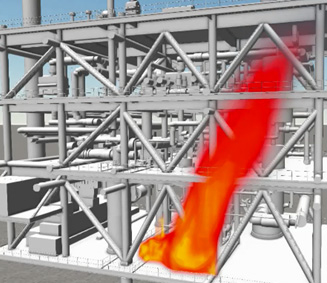

Fire, Explosion and Dispersion Analysis

Fire, Explosion and Dispersion Analysis using detailed 3D plant models is utilized to evaluate the impact of fires, explosions and the dispersion of flammable/toxic gases for plant facilities. Precise situations can be visualized by advanced CFD analysis, leading to safer, efficient and more reliable plant designs.

Capabilities

Operational reliability, essential for large and complex facilities such as LNG plants, requires comprehensive innovative design incorporating safety where conventional design techniques (eg: Design by Rule) cannot be applied. There is increasing demand for analysis throughout the course of design (Design by Analysis) and Chiyoda is developing and applying such advanced design technology, enhancing the safety of facilities and reducing environmental impacts through improved plant operational efficiency by predicting and mitigating potential problems in advance.

Applicable Range

Dynamic Simulation

- Refrigeration Systems: Compressor trips and restart simulations and determination of bypass valve requirements, parallel compressor trips, restarts and tie-ins after restart.

- Liquefaction Systems: Estimating LNG temperature trends following shutdown of main cryogenic heat exchanger.

- Steam Systems: Steam turbine trips and restarts, steam user trips.

- Fuel Gas Systems: Fuel gas compressor trips.

CFD Analysis

- Hot air recirculation analysis

- Flares and vents dispersion analysis

- Heat and fluid dynamics in pipes and equipment such as drums, columns and heat exchangers

Structural Analysis

- Equipment/piping thermal stress integrity assessments

- Equipment/piping FIV/AIV integrity assessments

Fire, Explosion and Dispersion Analysis

- Ventilation/dispersion analysis for prediction of flammable and toxic fluid concentration

- Pool jet fire analysis for prediction of radiation

- Explosion analysis for prediction of overpressure