Hydrogen and Carbon Monoxide Production Technology

Hydrogen is currently produced as feedstock for consumers from light hydrocarbons, such as natural gas, LPG and naphtha, at a rate of few hundred cubic meters per hour for consumers such as the semi-conductor or pharmaceutical industries etc, or at over 200,000 cubic meters per hour in hydrodesulphurization units for oil refineries.

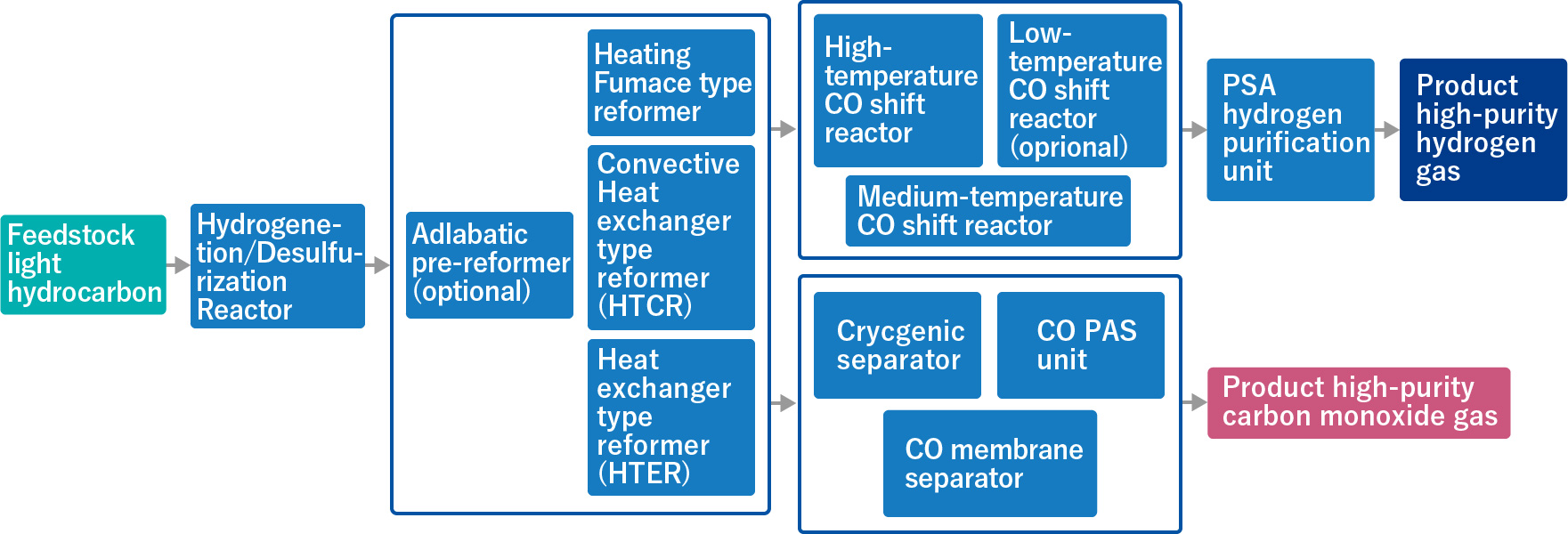

Producing hydrogen from light hydrocarbons comprises four stages: stage one is pre-treatment of raw materials to remove impurities, such as sulphur compounds, contained in the feedstock; stage two is the production of raw Synthesis Gas by steam reforming reactions of feedstock hydrocarbon; stage three (when hydrogen is required as the final product) is the reaction of CO in the raw Synthesis Gas with steam (CO shift reaction), converting the majority of CO into hydrogen to increase the hydrogen concentration; stage four is the introduction of hydrogen-rich raw Synthesis Gas into Pressure Swing Adsorption (PSA) units to remove CO2 and CO by adsorption to obtain high-purity (over 99.9%) hydrogen as the final product. If CO2 separation and recovery from Synthesis Gas is required, a CO2 removal system using an amine solution may be adopted. The core of hydrogen production technology is a reliable steam reforming process at temperatures of 800°C to 950°C.

High-purity CO can also be produced from raw Synthesis Gas produced by steam reforming, by applying CO purification and separation technologies, such as cryogenic separation, CO PSA, or CO membrane separation. CO is important in the chemical industry as a secondary feedstock for acetic acid production by methanol carbonylation, phosgene production, formic acid production etc.

Carbon Capture and Utilization (CCU) technologies are becoming increasingly important in the drive towards decarbonization. One method involves the production of Synthetic Gas through Reverse Water Gas Shift (RWGS) reaction using carbon dioxide (CO2) and hydrogen (H2). Processes that use gasification furnaces with Municipal Solid Waste (MSW) or biomass as raw materials to produce synthetic gas and the methanation process which produces e-methane, are also attracting attention.

Capabilities

The hydrogen and CO production technology offered by Chiyoda, originally developed and commercialized by Haldor Topsoe in Denmark, is currently adopted worldwide and Chiyoda has designed and constructed domestic and overseas hydrogen production plants based on the technology since 1954. Topsoe's latest hydrogen production technology has the following features:

- High energy efficiency

- Feedstock flexibility

- Tailor-made and flexible design

- High on-stream availability

- Safe and reliable operation

- Low investment cost

To demonstrate these features, Topsoe’s Side-fired Tubular Steam Reformer allows adoption of uniform and higher heat flux, resulting in reduced quantities of catalyst tubes with longer life expectancy, enabling safe and reliable operation with reduced risk of burner flame impingement. Of the two types of heat exchanger steam reformer offered by Topsoe, the Haldor Topsoe Convection Reformer (HTCR) utilizes the heat of combustion flue gas as the heat source for reaction and the Haldor Topsoe Exchange Reformer (HTER) utilizes the heat of the high temperature process gas as the heat source.

Compared to traditional technologies, it is now possible to propose the Advanced Autothermal Reforming (SynCOR) process, which can produce blue hydrogen with a CO2 capture rate of 95% to 99%, thereby reducing CO2 emissions in the hydrogen production process without the requirement for CO2 capture devices from combustion flue gases.