Hydrogen

Contributing to the Realization of a Hydrogen Society through Technology that delivers Optimal Solutions.

As a key energy source for achieving carbon neutrality, the demand for hydrogen is expected to increase due to the following characteristics:

Characteristic 1

Hydrogen does not emit carbon dioxide (CO2) when ignited.

Characteristic 2

Hydrogen can be 'produced' from multiple sources including renewable energy, oil and natural gas.

Characteristic 3

Hydrogen can be ‘stored’ and ‘transported’ in different forms.

Characteristic 4

Hydrogen can be ‘utilized’ for power generation, as fuel for vehicles, as a raw material and for producing heat, in a wide range of industries including petrochemicals and steel.

The Japanese government's ‘Basic Hydrogen Strategy’ establishes hydrogen use targets of approximately 3 mtpa by 2030, 12 mtpa by 2040 and 20 mtpa by 2050, in line with the increasing demand for hydrogen worldwide.

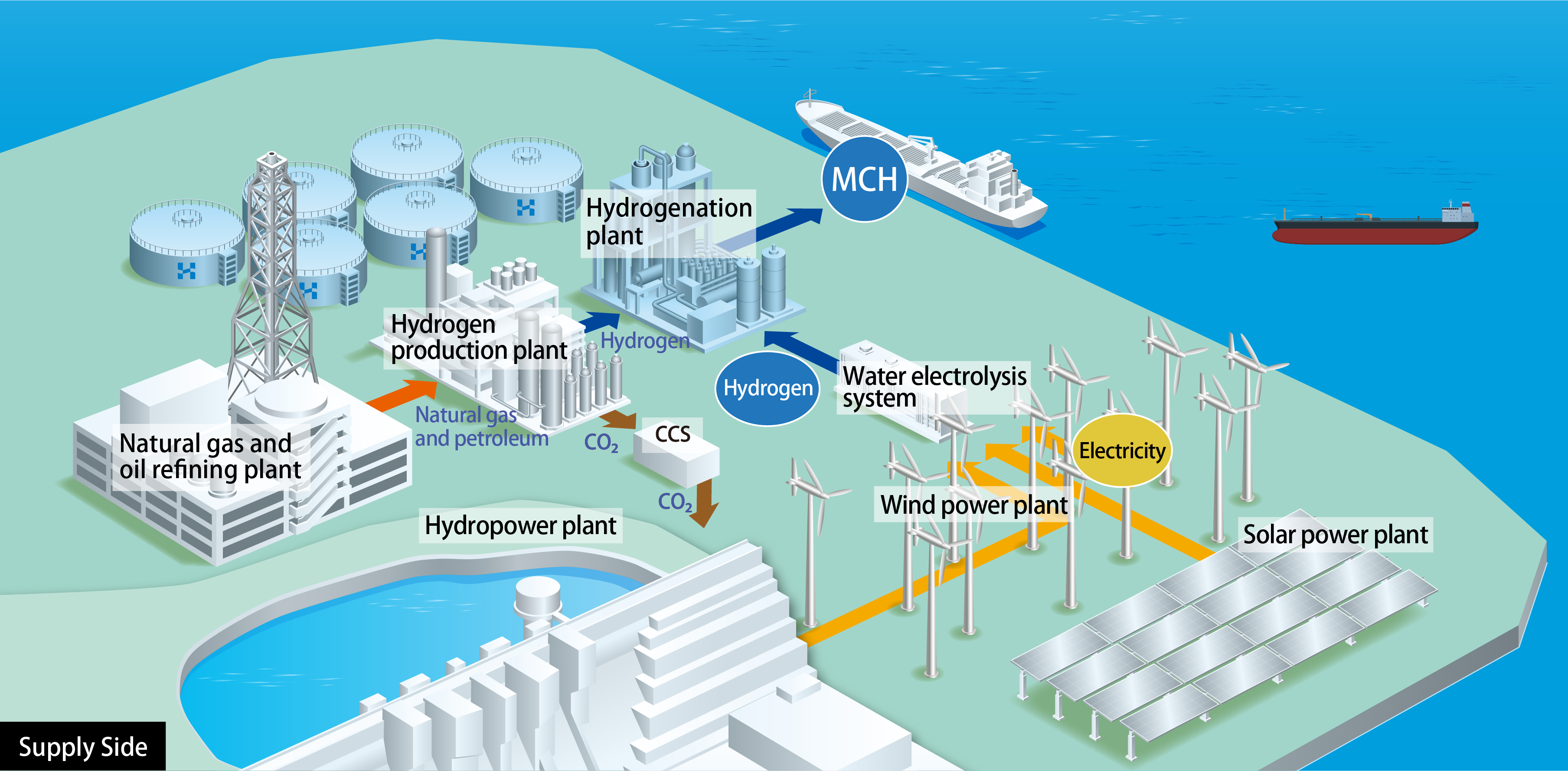

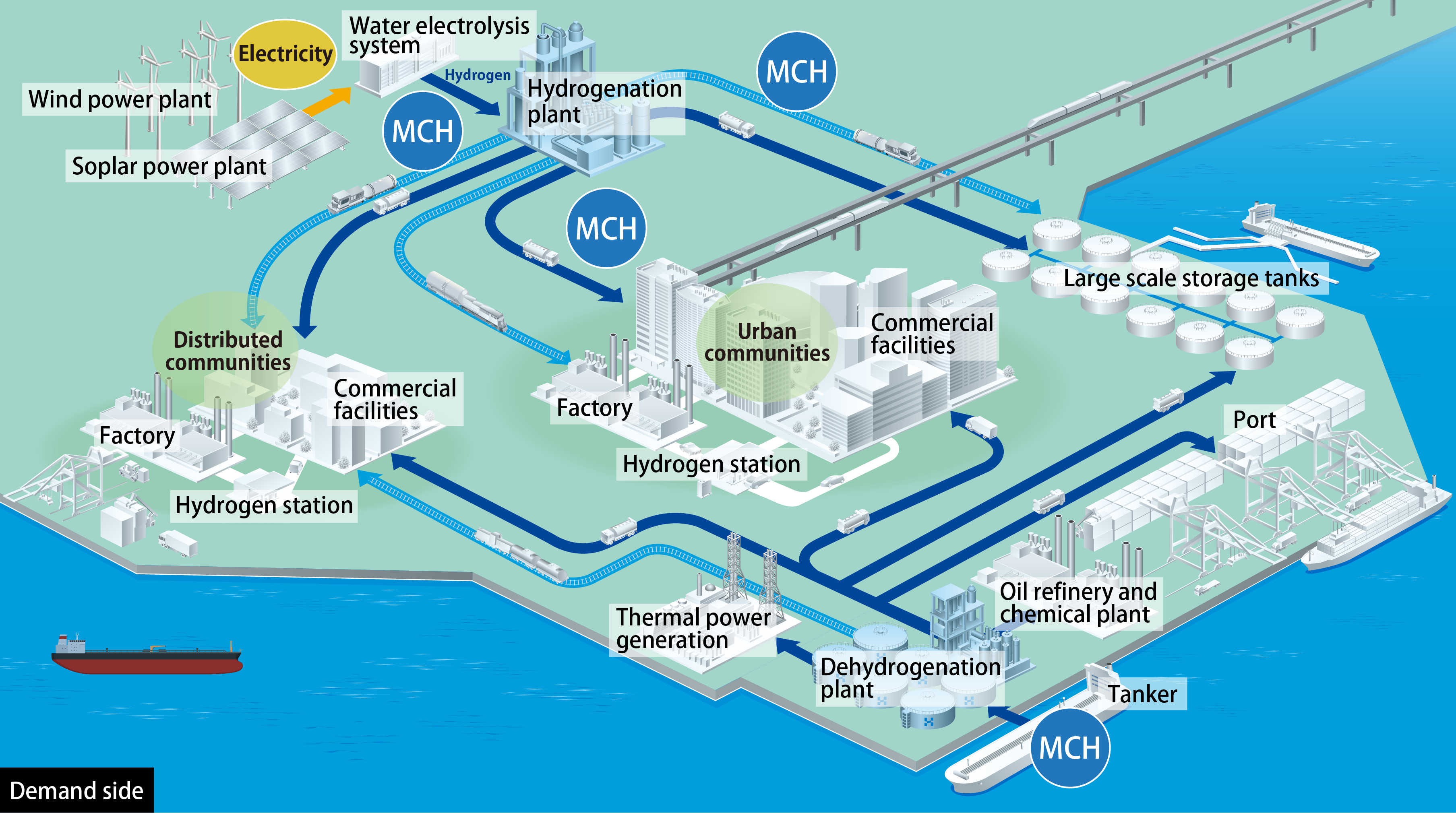

Chiyoda is contributing to the realization of a hydrogen society through technology that delivers optimal solutions, including development of 'Large-scale water electrolysis system' to produce hydrogen from water and our proprietary ‘SPERA Hydrogen’ LOHC-MCH* technology, for the safe and efficient long-term storage of commercial quantities of hydrogen and transportation over long distances using existing infrastructure, such as redundant oil storage tanks and conventional tankers, under current international laws, standards and regulations, facilitating the construction of supply chains for general hydrogen consumption.

- As a Liquid Organic Hydrogen Carrier (LOHC), methylcyclohexane (MCH) is a liquid at ambient temperature and pressure and is widely used in the manufacture of pharmaceuticals and as a solvent in correction fluids. MCH contains 530 times more hydrogen by unit volume than hydrogen gas, allowing for efficient and safe storage and transportation of hydrogen.

Chiyoda’s Hydrogen Community Vision

Chiyoda supports the global drive towards carbon neutrality by establishing hydrogen as the central energy resource in a future hydrogen society through the commercial development of hydrogen supply chains.

Initiatives for Establishing a Hydrogen Supply Chain

Chiyoda actively promotes the development of hydrogen supply chains, as illustrated below:

Hydrogen Production

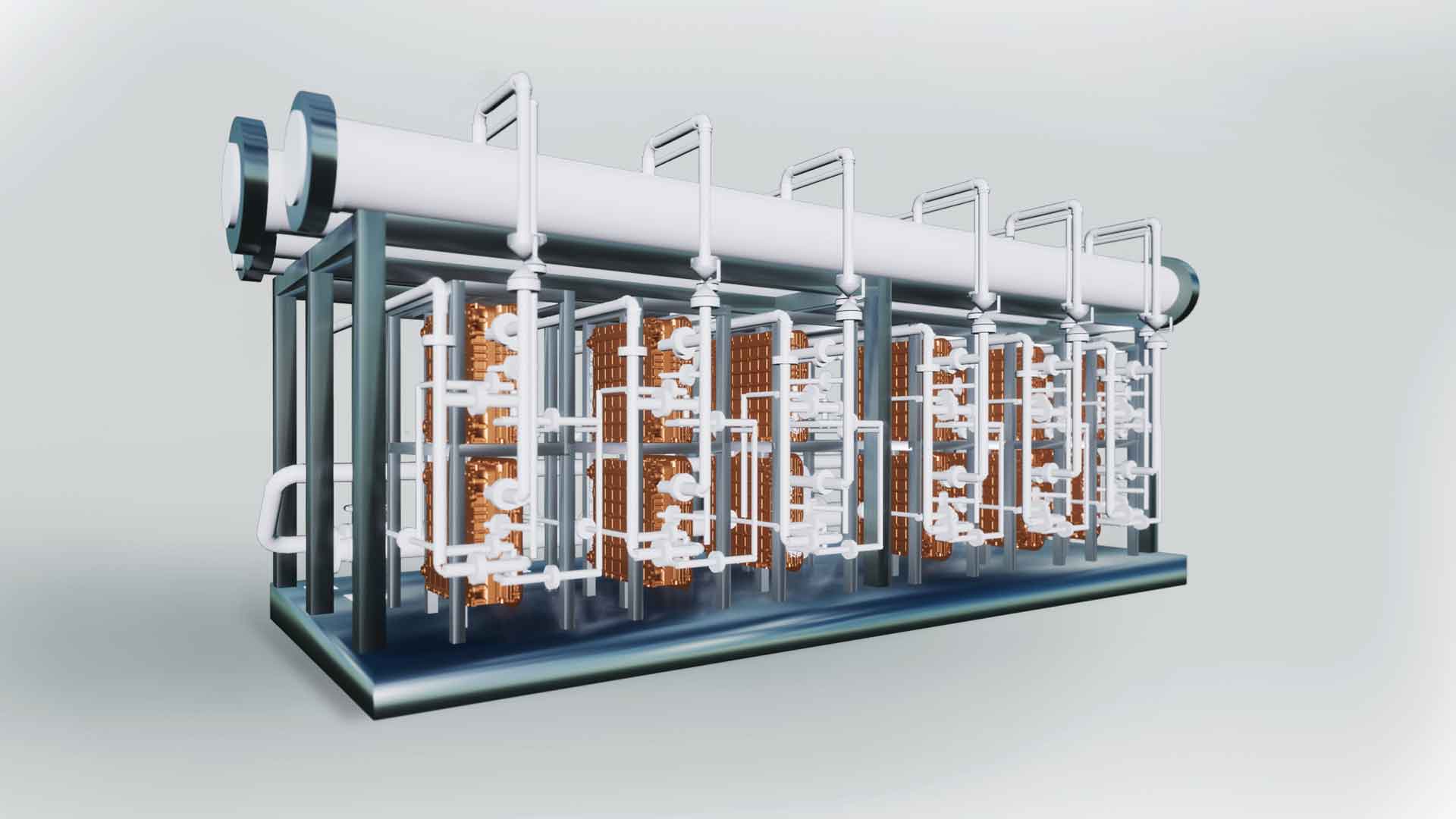

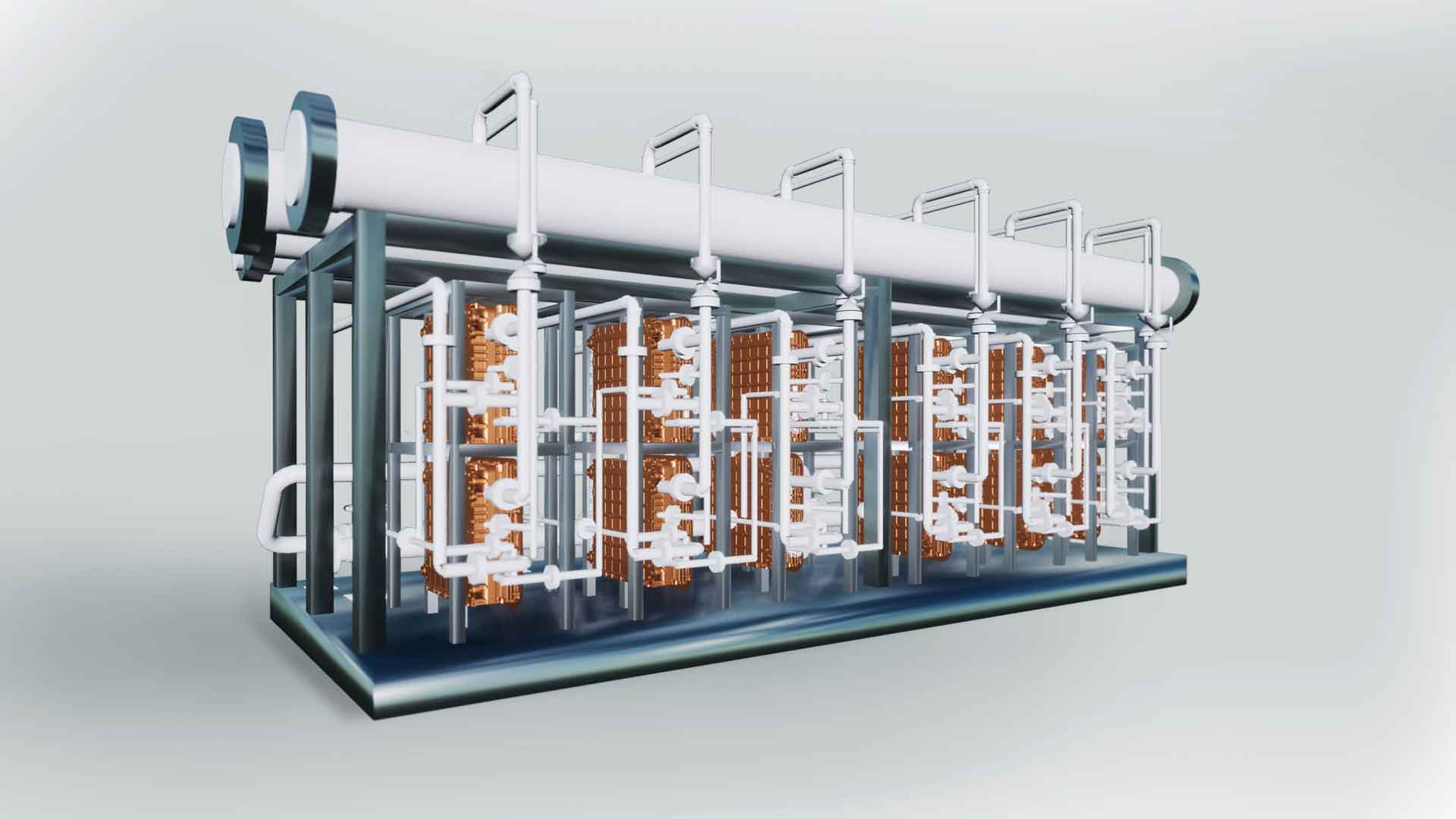

Development of a Large-scale Water Electrolysis System

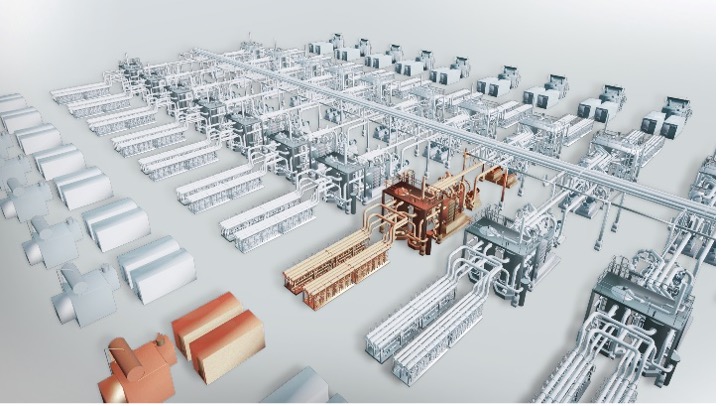

Chiyoda is collaborating with Toyota Motor Corporation in the development of a large-scale water electrolysis system, integrating and optimizing Toyota's fuel cell technology for water electrolysis cell stacks and our process plant design and construction technology for large-scale plants. The aim is to develop a competitive large-scale water electrolysis system to meet the rapidly expanding domestic and international hydrogen production market.

Key objectives include:

- Cost reductions, improved production efficiency and quality stabilization of water electrolysis systems required for green hydrogen production.

- Efficient hydrogen production in the range of 5MW-10MW as a basic unit, using an electrolysis system with an installation area of circa 2.5m x 6m (the world’s smallest) and a production capacity of approximately 100kg (5MW) - 200kg/hour (10MW). Systems can be combined, creating standardized packages to construct large-scale water electrolysis systems and meet customer demand.

- Water electrolysis systems will be installed into Toyota Motor Corporation's headquarters factory hydrogen park in FY2025, and enlarged to 20MW for demonstration and development purposes.

Chiyoda’s collaboration with Toyota contributes to advancing the development of large-scale electrolysis systems worldwide, increasing global energy security and supporting the Japanese government's ‘Hydrogen Basic Strategy’ goal of introducing 15GW of water electrolysis equipment globally by 2030 with Japanese company involvement, and enabling the production and supply of hydrogen to realize national and international clean energy objectives.

Image of Jointly Developed Water Electrolysis System

(Highly integrated water electrolysis stack group, produced by Toyota)

(Smart scalable engineering by Chiyoda Corporation)

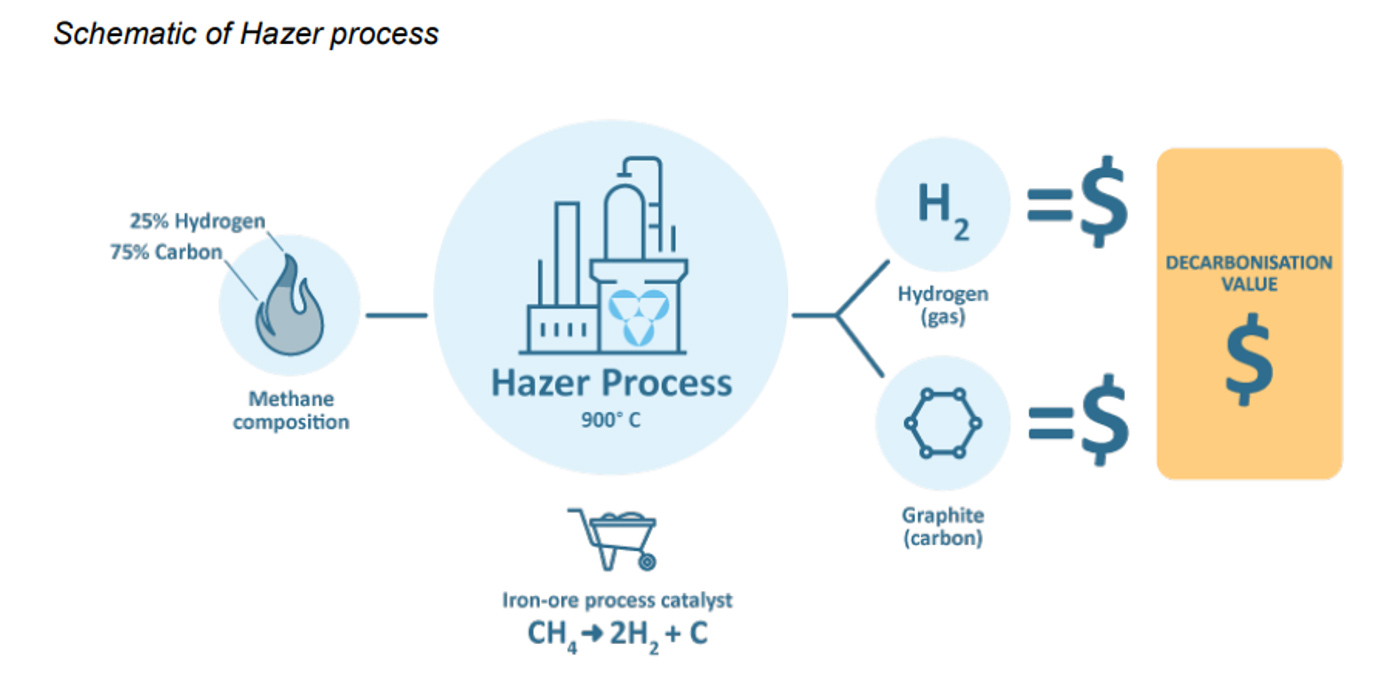

Methane Thermal Decomposition for Hydrogen Production

Chiyoda is collaborating with Australia's Hazer Group Limited in a project utilizing the Hazer Process to produce hydrogen and graphite simultaneously through the thermal decomposition of methane biogas. The project aims to assess the technological and economic feasibility in the Chubu region, with the goal of commencing demonstration test in the later 2020s. The initial hydrogen production capacity is projected to range from 2,500 tons to 10,000 tons per year, ultimately aiming for a hydrogen production capacity of 50,000 to 100,000 tons per year.

Transporting and Storing Hydrogen

World’ First Global Hydrogen Supply Chain Demonstration Prohect

Chiyoda successfully completed the world's first global hydrogen supply chain demonstration project using MCH in 2020, and we continue to advance the development of further chains.

World’s First Marine Transport of MCH by Chemical Tanker

In February 2022, we successfully carried out the world's first maritime transportation of MCH using a conventional chemical tanker.

Utilizing Hydrogen

SPERA Hydrogen Supplied as Fuel for Gas Turbine Power Generation for the First Time in Japan

In the world’s first global hydrogen supply chain demonstration project, hydrogen transported in the form of MCH from Brunei was supplied to the gas turbine of Mizue Power Station, operated by Toa Oil Co., Ltd., at their Keihin Refinery in Japan in 2020. This marked the first utilization of hydrogen for power generation in Japan.

Distributed Hydrogen Supply

- As part of a New Energy and Industrial Technology Development Organization (NEDO) subsidy program from FY2016 to FY2018, Chiyoda demonstrated on-site hydrogen stations as a decentralized hydrogen supply solution and successfully achieved miniaturization of hydrogen dehydrogenation equipment.

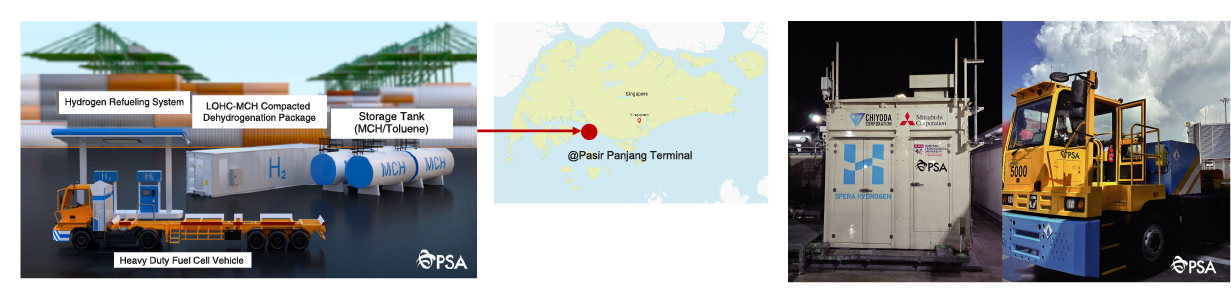

- In early 2024, Chiyoda commenced an MCH Dehydrogenation Refueling Station demonstration project in Singapore to operate heavy duty Fuel Cell Vehicles (FCV) with imported hydrogen at Pasir Panjang Terminal as the MCH Compacted Dehydrogenation Package in use for decentralized applications of imported hydrogen.

Future Hydrogen Utilization

- Hydrogen is expected to be utilized as feedstock and as a source of heat in a multitude of industries including power generation, fuel for transport, steel production and the petrochemical industry.

- MCH can be stored in tanks as a large-scale energy reserve and hydrogen extracted as required.

Initiatives to Reduce Hydrogen Supply Costs

The Japanese government's ‘Basic Hydrogen Strategy’ establishes targets to reduce hydrogen supply costs from the current 100 yen/Nm3 to 30 yen/Nm3 by 2030 and 20 yen/Nm3 by 2050, essential for the realization of a hydrogen society. Chiyoda’s technology optimizes the entire hydrogen supply chain, reducing the costs of hydrogen supply.