Simulations

Simulations are used in Life Science Facility Planning, including the Design of Bioreactors.

Chiyoda’s technologies, developments, achievements and approach to new projects

Computational Fluid Dynamics (CFD) simulation technology has been applied to various fields (e.g. design of plant and devices, and their developments). Chiyoda could combine diverse engineering technologies which Chiyoda has cherished for a long time and the most advanced CFD technology, hence could provide them to a client to create a new value for a client.

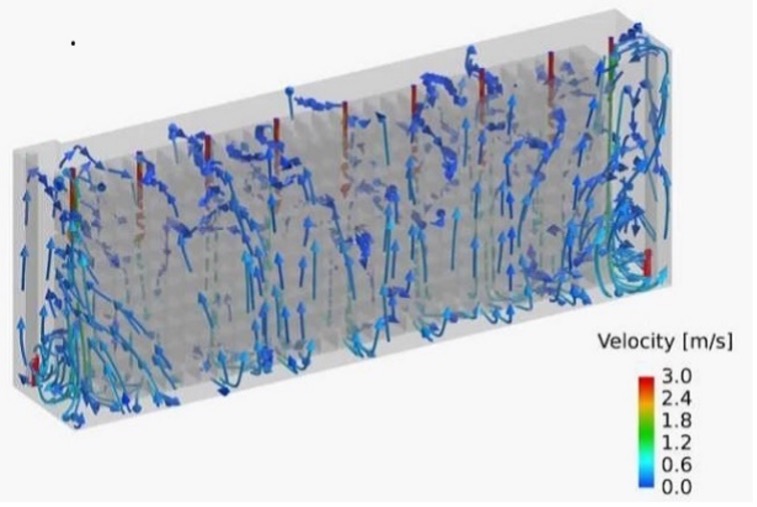

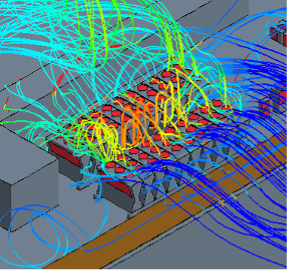

Computational Fluid Dynamics (CFD) Simulation enables you to visualize and quantitatively understand complex flow patterns and profiles of temperature, concentration, etc. inside of the equipment and clean rooms that are not normally observed. CFD simulation can be widely applied to design and engineering in order to optimize design and improve reliability, for example, the arrangement with less stagnant air flow of air conditioner for a clean room, scale-up engineering for fermenters (mixing vessels). Simulation enables you to optimize the design and improve the reliability of the facility.

Chiyoda delivers comprehensive solutions to customers as detailed below, ranging from consultation, data collection and analyzing results to proposing plant efficiency improvement solutions, by applying its extensive CFD technology experience in plant design, R&D and plant diagnosis consulting.

- Optimization Study of a Fermenter Geometry (e.g. L/D Ratio, Mixing Blade Design, and Sparger Design), and Operating Conditions (e.g. Aeration and Mixing).

- Scale-up Study and Consulting for Fermenters

- Equivalent Study as to Flow Dynamics in Mixing Vessels at Scale-up of their Vessel Capacities

- Evaluation of Air Flow Pattern in Clean Rooms and Dispersion Study of Exhausted Air Flow from Buildings

- Examination of airflow pattern in Vivariums