Biopharmaceuticals

Abundant Experiences from Initial Clinical Scale Size Equipment to 20m3 Commercial Manufacturing Scale Plants for Various Biological Species

Chiyoda’s technologies, developments, achievements and approach to new projects

- Design in consideration of Reduction of Bioburden

- Design complying with Handling Biological Hazard

- Optimization Proposal for Operation Rate of Upstream Processes and Downstream Processes as to Configuration of Facilities

- Appropriate Selection and Design of Single-use Systems

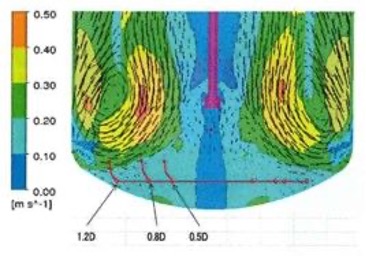

- Optimization of Culture Conditions by Simulation

Chiyoda has various experiences of design and construction in antibody products and vaccine plants with large scale-up to 20m3 capacity and facilities using many SUBs (single-use bags).

Our experiences include manufacturing plants for an Active Pharmaceutical Ingredient (API) for the coronavirus vaccine (COVID-19) and antibody pharmaceuticals.

In animal cell culture and purification, Chiyoda has various experiences of design and construction of facilities from using SUB (single-use bags) for clinical trials to 10m3 manufacturing capacity.

In addition, from culture of skin cells to design of cell culture system in space enviroment, Chiyoda has wide range of abundant knowledge in various fields.

Chiyoda has designed and constructed single-use fermenters from a few liters oscillated reactors up to 2,000 liters mixing vessels.

In vaccine preparation, Chiyoda has many design and construction experiences of stainless steel culture tanks (for insect cells) with around 20m3 capacity and large-sized cell culture vessels and also has extensive knowledge of sterilization and cleaning for facilities.

Chiyoda would offer various O2/CO2 dynamic simulation (CFD) analysis and optimal facility design (configuration/size) using batch simulators.

- Photo by courtesy of Unigen Inc.