Technical Consulting

Advanced Pharmaceutical Development and Manufacturing Solutions

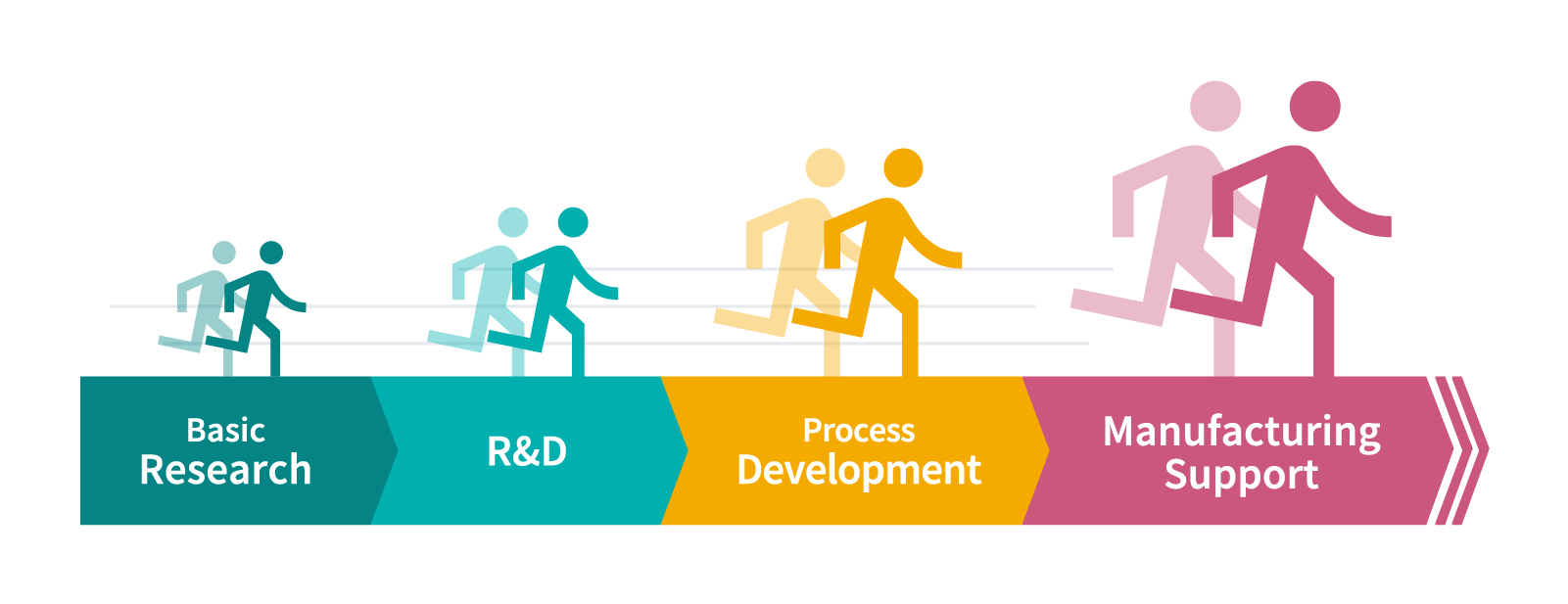

Advanced therapeutic products, such as biopharmaceuticals and regenerative medicine, require regulatory compliance, adherence to guidelines, and technological expertise that surpass existing standards. This includes aspects such as pharmacological principles, evaluation tests, and manufacturing process development. Chiyoda provides strategic and technical solutions that span from research and development to product launch and manufacturing support. Our services include improving pharmaceutical quality, ensuring stable sharing, and reducing manufacturing costs. As a leading developer and provider of advanced therapeutic product solutions, we collaborate closely with our customers to achieve common goals.

We operate three facilities to support each phase of development: the CLP (Chiyoda Life Science Technology Park) laboratory at our Koyasu Office Research Park, the TSL (Tsukuba Stem Cell Laboratory) established in partnership with the National University Corporation, Tsukuba University, and the TACT (Tsukuba Advanced Cell Therapy Facility), which serves as a cell processing facility.

At TSL, we bridge basic research and development by acquiring the latest technological information from a cellular biology perspective, which serves as the foundation for regenerative medicine products and cell pharmaceuticals, alongside our academic network.

The CLP is equipped with laboratories and systems that ensure the quality of experimental data, functioning as a base for examining and verifying manufacturing processes and quality evaluation conditions during development, thereby linking research and manufacturing.

TACT will act as a manufacturing demonstration facility for physician-led clinical trials, in collaboration with Tsukuba University and Tsukuba University Hospital, as part of the 'Tsukuba Digital Bio International Base'*1 initiative.

We aim to create an environment where academia, medical institutions, and companies can work closely together toward practical applications.

By leveraging these three facilities, we provide services that support the development of foundational technologies for regenerative medicine products and establish manufacturing processes and operations at the physician-led clinical trial level, functioning as a CRDMO (Contract Research, Development, and Manufacturing Organization) in the field of regenerative medicine.

- Tsukuba Digital-Bio International Center

Based on the ‘Creation of Collaborative Innovation Hubs’ program, supported by the Japan Science and Technology Agency (JST), to establish hubs that utilize bioresources and digital technologies in Tsukuba, enabling interdisciplinary research to support the well-being of all generations and contribute to the realization of a better society.

Tsukuba Digital-Bio International Center

Key Technical Consultation Areas

Chiyoda formulates business proposals for customers related to life sciences, maximizing their business potential and delivering customized solutions and new value propositions to meet customer needs, with a commitment to providing sustainable services.

Regenerative Medicine

Regenerative medicine products, including cell therapies, are brought to market following a well-defined product concept and thorough research and development, along with regulatory review. We provide comprehensive support through strategic and technical consultations, working collaboratively throughout the entire research and development process.

Our focus is on iPS cells, MSCs (mesenchymal stem cells), and immune cells.

We actively integrate AI/DX not only to standardize manufacturing processes for scale-up but also to enhance traditional manufacturing methods known as scale-out, which involves the transfer of technology from manual cultivation (hand-culturing) to mechanization We assist in developing analytical procedures as well. These technologies and methodologies are designed for practical application in manufacturing settings, leveraging the manufacturing and quality management expertise accumulated at TACT. This approach ensures seamless development, ultimately reducing both the time and costs associated with bringing products to market.

Additionally, TSL serves as a knowledge hub, continuously gathering the latest research findings and technological advancements, including Microphysiological Systems (MPS), to facilitate progressive responses.

Small Molecule Pharmaceuticals

The introduction of continuous production technology is advantageous in reducing manufacturing process development periods in the pharmaceutical development stage, increasing efficiency by reducing labor and saving space in commercial production, ensuring safety in reaction processes involving hazardous substances and providing quality assurance for high-quality pharmaceuticals. We offer various type of services, including catalyst development, which is an important element in continuous production, contracted experiments using our own flow synthesis equipment, and design & manufacturing of flow synthesis equipment (pilot and commercial under GMP requirement).

Cell Culture Technologies

Efficient cultivation of microbes or cells tailored to specific purposes is required in the fields of smart cells, biopharmaceuticals and regenerative medicine. Chiyoda applies CFD and AI / machine learning expertise accrued in the energy sector to this field, addressing challenges related to cultivation. We provide comprehensive support from the operation and management of appropriate control methods during cultivation to facility maintenance, troubleshooting to reduce costs. By utilizing culture digital twins for customized bioreactors and developing efficient manufacturing expertise, we reduce development periods, optimize manufacturing methods, stabilize the supply of pharmaceuticals and minimize costs by applying our differentiated technologies.