Engineering

Chiyoda is a fully integrated engineering company with an unrivalled spectrum of specialists in fields such civil, engineering, mechanical engineering, electrical and instrumentation engineering, process engineering and many more, located in its head office and in satellite engineering offices across the globe. Engineering activities are undertaken collaboratively, with close cooperation across geographical and discipline boundaries, using consistent IT technology and forums ensuring effective communication and consistency of output. Based on the ‘Basic Design Package’ developed during FEED and the Process Design, facilities design such as equipment/electrical/control & systems and space-integration design such as piping/civil/ building are performed in parallel. Engineering input is required during early the concept phase, including ‘in-house’ engineering expertise and, as far as is reasonably practicable, subcontractor and vendor design expertise, to ensure aspects such as, health and safety and the environment, quality, construction and commissioning, constructability, risk and opportunity analysis, productivity, plant operation and maintenance and operability and reliability etc are incorporated as early as possible. Engineering input is also required to evaluate and incorporate local and site conditions, such as geotechnical/geophysical/geological considerations, climate etc. Engineering databases, compiled and updated over many years of successful global project execution, and common IT communication forums are utilized to ensure effective sharing of information/skills.

Engineering Tools

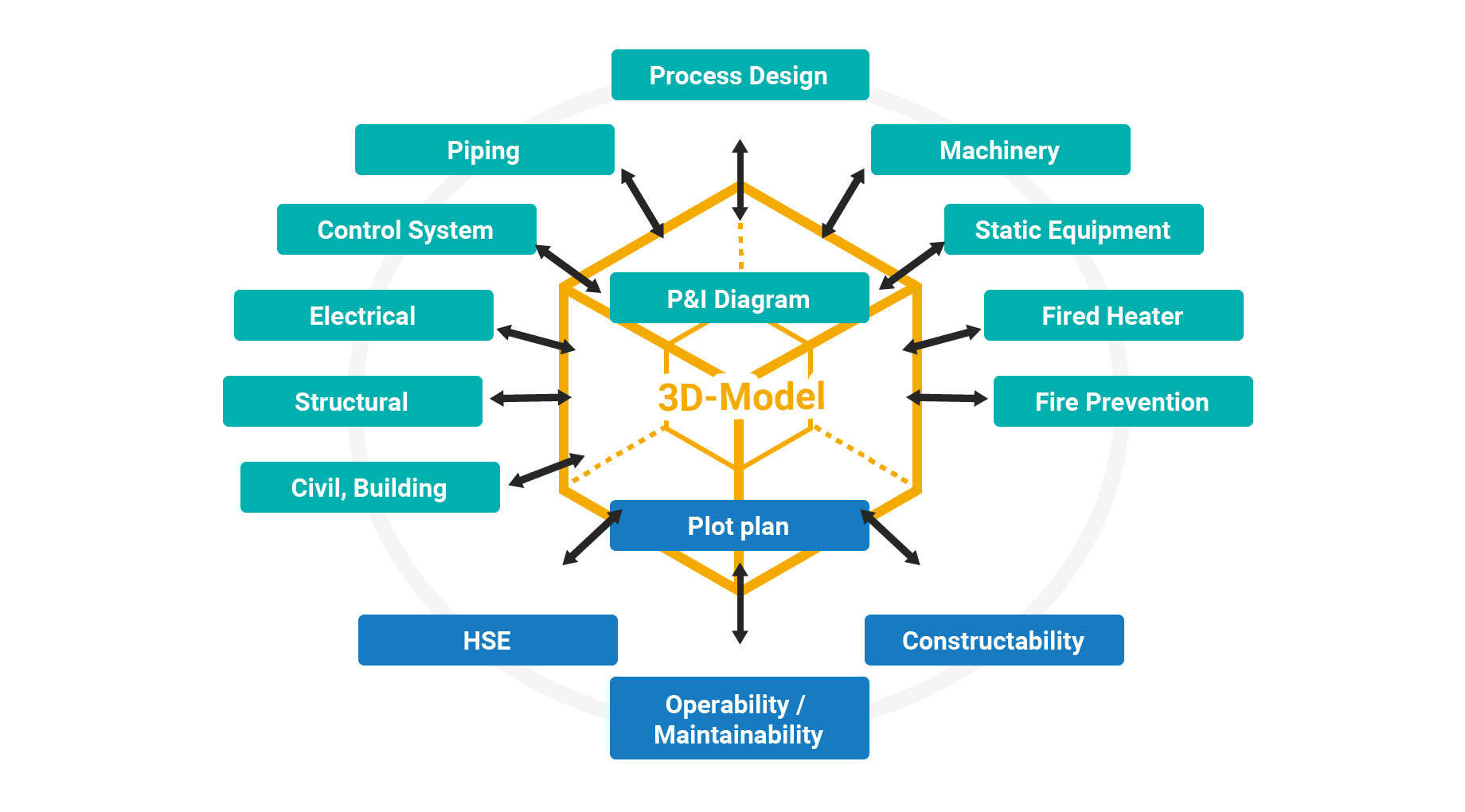

State-of-the-art engineering tools that are implemented across international geographical boundaries and between engineering, procurement and construction teams, including support disciplines such as health and safety, quality etc, include P&IDs*1 serving as the blueprint for plant design, virtual 3D plant models constructed virtually in 3D and Plot Plan development incorporating optimal equipment placement are prepared and developed by State-of-the-art engineering tools and are finalized through Cold Eye Reviews*2 conducted at designated steps. This system enables that Global Engineering Centers work in linked and integrated manner.

- Piping & Instrument Diagram:

A schematical diagram showing piping, equipment and instrumentation connections within process units in various kinds of industrial plants. During the design stage, the diagram also provides the basis for the development of system control schemes and allows further safety and operational studies. - Cold Eye Reviews

A reliability improvement program involving independent reviewers conducting reviews of the design content, project plans and project progress. A proactive approach allowing prompt identification of potential issues and facilitating corrective and preventive actions.

Intensive Design Reviews

Chiyoda conduct Intensive Design Review, in which senior engineers from broad view and higher-level viewpoints conduct verification of the performed designs and issues across multi-disciplines to ensure the optimized design and engineering reliability.