Pioneering a water electrolysis system market with Japanese technology

── Coa you please inform us of the process that led to the strategic partnership with Toyota?

Yasunishi

The initial catalyst was both companies participating as members in a cross-industry council aimed at building a supply chain for the expansion and stable use of hydrogen. This sparked discussions on what we could achieve as a team. The development of water electrolysis systems is currently led by overseas companies. Our shared aspiration of implementing water electrolysis systems in society using Japanese technology became the driving force behind our partnership.

Yoshida

The efficient agreement on this partnership was largely due to a mood of "let's do it together as one team" that evolved naturally through discussions on the operational side, rather than top-down. The Japanese government, in its ‘Basic Hydrogen Strategy’, aims to secure a 10% share (15GW) of the global water electrolysis system market by 2030 for Japanese companies. We aim to contribute to achieving this goal by joining forces with Toyota.

Yasunishi

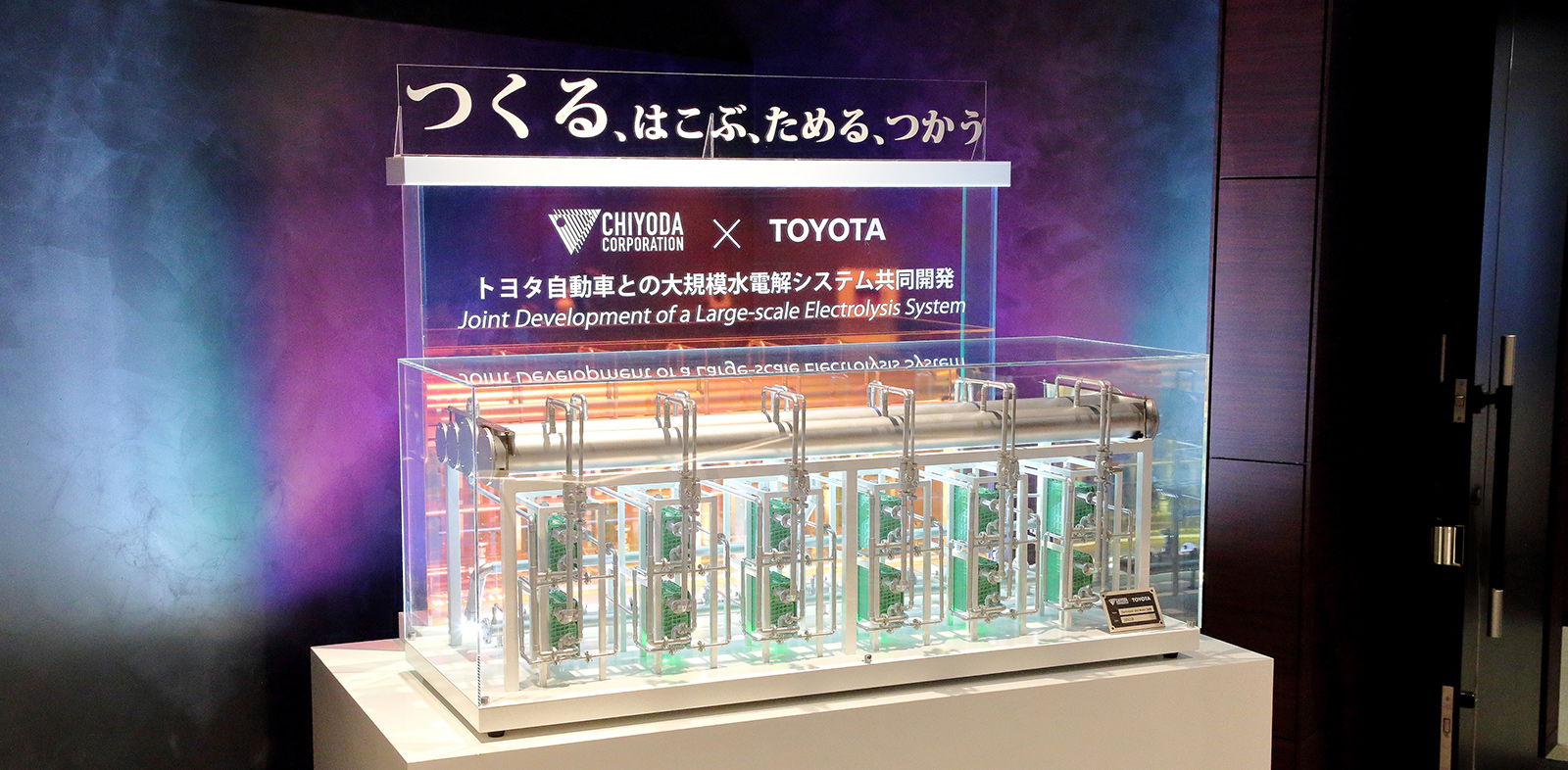

In this project, we are developing a ‘water electrolysis system’ that generates hydrogen by electrolyzing water, by repurposing the mechanism of the fuel cell stack, a key technology of the fuel cell vehicle MIRAI, which produces water from hydrogen and oxygen and uses the electric energy generated in the process to drive the motor. By combining Toyota's electrolysis cell stack technology with Chiyoda’s plant expertise, we are jointly developing a large-scale water electrolysis system as a new market entrant.

Project Overview: Water Electrolysis System

We are developing a water electrolysis system that, despite being the world’s smallest, has a high hydrogen production efficiency to more effectively respond to customer needs. Specifically, we are developing 5MW-10MW class equipment as the basic unit (floor area: 2.5m x 6m, hydrogen production capacity: approx. 100kg / hour), for multiplication to create a standard package, allowing the construction of large-scale water electrolysis systems. The concept for a 5MW water electrolysis system is complete and, looking forward to future large-scale hydrogen production, we are currently developing a highly efficient 20MW-class system. Commencing from the fiscal year 2025, we plan to introduce the water electrolysis system in the Hydrogen Park at the Toyota Honsha Plant for verification and development.

Leveraging our Engineering Strengths in 'Nurturing, Connecting, and Socially Implementing New Technologies’

── What strengths or expertise is Chiyoda bringing to the project?

Koyama

Using our proprietary technology, SPERA Hydrogen™, Chiyoda successfully conducted the world’s first global hydrogen supply chain demonstration project from 2015 to 2020 to 'transport and store' hydrogen. The insights and expertise from the overseas green hydrogen market that originated from SPERA Hydrogen™ business development are essential in advancing this project. The water electrolysis system is composed of multiple components such as rectifiers and separators, as well as the electrolysis cell stack developed by Toyota. We introduced our module construction* expertise (used in large scale industrial plant construction), to simplify the installation of devices for customers and improve quality. Our project management expertise, cultivated from the successful completion of global projects, is also key to advancing technology development. Chiyoda’s strength as an integrated engineering company lies in 'nurturing, connecting and implementing new technologies' and we continue to leverage our strengths in response to customer requests.

- A construction method that assembles facility structures (modules) at locations separate from the construction site, for transportation to site by ship and overland for connection to adjacent modules, significantly reducing on site man-hours and minimizing construction schedules.

Yasunishi

Our expertise and extensive experience in large-scale plant engineering is also essential to optimize scale up, combining small-scale 5MW-10MW class equipment to meet customer requirements for hydrogen use and installation.

Koyama

That's exactly right. Although the configuration of the water electrolysis system is not relatively complex, it's crucial to ensure the system functions with no complications. Comparing it to a human body, the electrolysis cell stack developed by Toyota, which generates hydrogen from water, would be equivalent to the heart of the water electrolysis system. One of our major roles is to design the optimal combination of components to efficiently circulate the ‘blood’ throughout the water electrolysis system. For example, we are flexibly responding by continuously adjusting issues such as the layout for ease of construction, or control methods that maximize the performance of the electrolysis cell stack, depending on the scale and specifications of the system.

Contributing to the Acceleration of Supply Chain Construction for 'Creating, Transporting, Storing and Using' Hydrogen

── Hydrogen will be key for achieving a decarbonized society. Can you please tell us about the goal of this project?

Hojo

Our goal is to achieve an annual production of 1 GW of water electrolysis systems by 2030. A crucial factor in promoting the widespread adoption and expansion of water electrolysis systems is reducing hydrogen production costs. The Japanese government's basic hydrogen strategy sets a target of 30 yen/Nm3 for hydrogen supply costs (CIF cost) by 2030 and 20 yen/Nm3 by 2050. If we cannot achieve low-cost hydrogen production, it will be difficult for the business to succeed and for widespread hydrogen adoption and utilization. Reducing hydrogen production costs in customer lifecycles is also important.

Yasunishi

When we look at the cost structure of water electrolysis systems, the largest proportion is electricity required for electrolysis. To reduce hydrogen production costs, it is crucial to minimize electricity costs. We can leverage our expertise in energy management, gained from designing and constructing large-scale solar power plants, large-scale battery energy storage systems and implementing advanced power system management.

Hojo

That's right. Energy management can be seen as the ‘brain’ that provides instructions and commands to ensure efficient functioning of the system. We can also apply our strengths in this area.

── Please tell us about the significance of this project in realizing a hydrogen society.

Hojo

The realization of a hydrogen society requires establishing supply chains that include producing, transporting, storing and using hydrogen. Chiyoda has primarily focused on transportation and storage, but by expanding into hydrogen production through this project, we can also contribute to the acceleration of supply chain development and provide more comprehensive solutions.

Yoshida

This project involves launching a hydrogen supply chain construction business, which can be viewed as developing infrastructure from scratch. The project is a significant challenge, but it also greatly enhances the realization of a hydrogen society and is a hugely rewarding endeavor. The market for water electrolysis systems is currently led by foreign companies, particularly in Germany. However, if our system is adopted globally, it will bring us ‘one step closer’ to realizing a hydrogen society and will contribute to Japan's energy security.

Yasunishi

While we aim to promote and expand large-scale water electrolysis systems, there are also expectations for the utilization of hydrogen in applications such as small-scale hydrogen stations. The hydrogen business currently envisions producing large quantities of hydrogen in regions where it can be produced cheaply, for transportation to demand areas. Reducing the costs associated with large-scale transportation and storage has become a major challenge requiring a re-evaluation of the locally produced concept for local consumption. The development of infrastructure that enables hydrogen to be used in locations that are closer to everyday life will contribute to the realization of a hydrogen society.

Effective collaboration, where all participants can offer frank opinions, is a driving force.

── What are your thoughts on collaborative initiatives with partners such as Toyota?

Yoshida

To continue our business in the energy field, it is essential to engage in initiatives that prioritize carbon neutrality. Technological developments towards the realization of a decarbonized society are ongoing and it remains uncertain which will become the main contender. It is not therefore realistic for our company to carry out all future measures in isolation. Collaboration that leverages the strengths of each participant company is essential. In this project, we were able to leverage the strengths of both parties, with Toyota as the ‘pro of industrial products’ and Chiyoda as the ‘pro of facilities’. Moving forward, we will also expand our collaboration to other fields.

Yasunishi

Communication is crucial to successfully advancing projects in collaboration with partners. In this project, it was great that we were able to dive into discussions with Toyota without hesitation and communicate openly from the initial team building stage.

Koyama

Through almost daily meetings with Toyota to discuss various topics, we have developed a great relationship where we can openly exchange frank opinions without hesitation. Toyota operates in a different industry and there are many differences in terminology and definitions of data, even for simple things used in our daily work. However, by taking the time to discuss these differences, the distance between our two companies naturally shrinks.

Yoshida

Collaboration is also steadily advancing in sales activities. Toyota has received inquiries from interested companies since the project started and we have joined the meetings. Conversely, when we receive inquiries from customers related to energy, we invite Toyota to join us and listen to specific requests together.

Maximizing the value of the system and aiming for early market entry

── Please share the current challenges and your thoughts on how to solve them.

Hojo

The main challenge is how to maximize the potential of the electrolysis cell stack, which is the core component of the water electrolysis system. This is the key issue that needs to be addressed. Toyota is actively working on continuous improvement and we are engaged in ‘trial and error’ to overcome this challenge and maximize the value of the system.

Koyama

Although we are relative latecomers in the field of water electrolysis and are striving to create something distinctive to differentiate ourselves, it is crucial to enter the market as soon as possible. Deciding when to do this is a challenging balance. Our products are refined by having customers use our products and immediately respond with improvement proposals. It is a question of timing for future social implementation. We are aligning closely with Toyota and aim for a full-scale rollout by fiscal year 2027.

Yasunishi

Indeed, that is a crucial point. I have experienced launching several new businesses and understand that customers can be cautious when it comes to adopting new systems. It will be challenging to convince customers to be the first to adopt a water electrolysis system. However, once we are able to sell the first unit, it should open up new possibilities and I am eager to make it happen as soon as possible.

Aiming for project success and redrawing the hydrogen world map!

── Finally, please share your visions and dreams for this project and the future.

Hojo

As Mr. Yasunishi mentioned, my priority is to get the first unit up and running as soon as possible. To achieve this, it is crucial for us to develop a system that is more appealing compared to our competitors. I believe that fulfilling this role will bring us closer to realizing a decarbonized society. With this in mind, I will continue to work hard to make it happen.

Yoshida

My dream is to contribute to the widespread adoption and expansion of water electrolysis systems, and to redraw the global map of the hydrogen market, leveraging our partnership with Toyota, a globally renowned company representing Japan.

Koyama

I hope to make this project a success such that it is recognized in society as a model case, symbolizing Chiyoda’s purpose of ‘Enriching Society through Engineering Value.’

Yasunishi

I agree. To realize Chiyoda's purpose and change the world, we need to succeed in large-scale projects which would contribute to the stabilization of company management and expand new collaborative initiatives in a wide range of business areas. We will continue to accept new challenges as ‘One Team’ to realize a scale of 1GW annual production by 2030 through collaboration with Toyota for future business prosperity and to benefit the world!

In countries like Japan which lack natural energy resources, the development and widespread adoption of locally-made hydrogen production facilities to create energy is a source of immense hope. We strongly feel the expectations placed upon Chiyoda and Toyota by the Japanese government.

With its ability to transform into alternative forms of energy, hydrogen serves as an interface connecting over 5.5 million automobile users and many other stakeholders. The possibilities this presents are exciting.

Whenever we meet with the Chiyoda team, we are struck by their confidence and expertise in this field. It is clear to us that this confidence stems from Chiyoda’s history of competing on the global stage. For those of us working in the equipment sector, Chiyoda is an incredibly reliable and inspiring partner.

We have a saying at Toyota: "Open the shoji screen (door) and look outside—the world is vast." This sentiment resonates with us daily as we explore new opportunities and challenges.

We are grateful for the opportunity to collaborate with Chiyoda on this project, contributing to a better future for our children and the planet through Japanese technology. Together, let’s merge plant engineering and automotive innovation to create one-of-a-kind, exceptional products.

Group Manager

Tomoyuki Kogo