Establishing a Hydrogen Supply Chain by Leveraging the Technical Expertise and Network of an Integrated Engineering Company.

──What role is Chiyoda aiming to play in realizing a hydrogen society?

Morikami

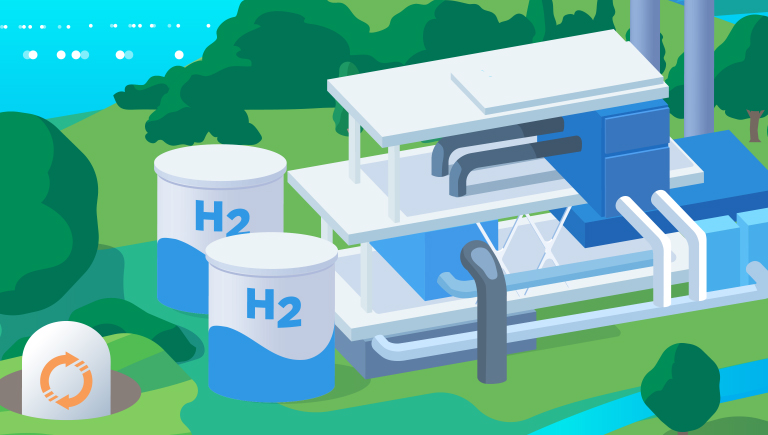

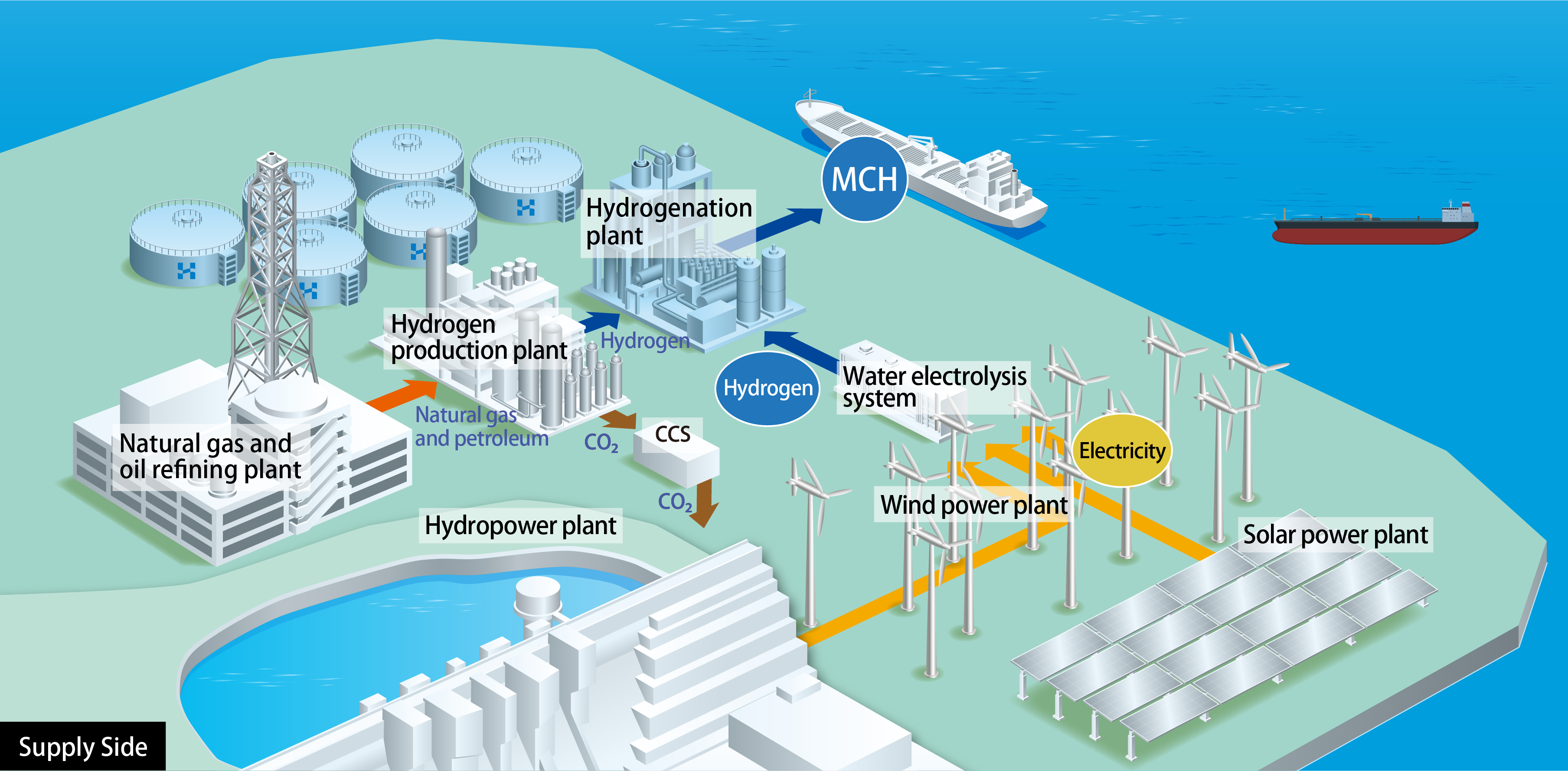

Realizing a hydrogen society requires the development of a supply chain to safely, reliably and efficiently supply hydrogen in large quantities to end-users in a multitude of sectors. Our unique capabilities of cultivating, integrating and socially implementing technologies, the value proposition of an integrated engineering company, enable us to optimize a ‘produce, store and transport’ hydrogen supply chain, with renewable energy as the primary source.

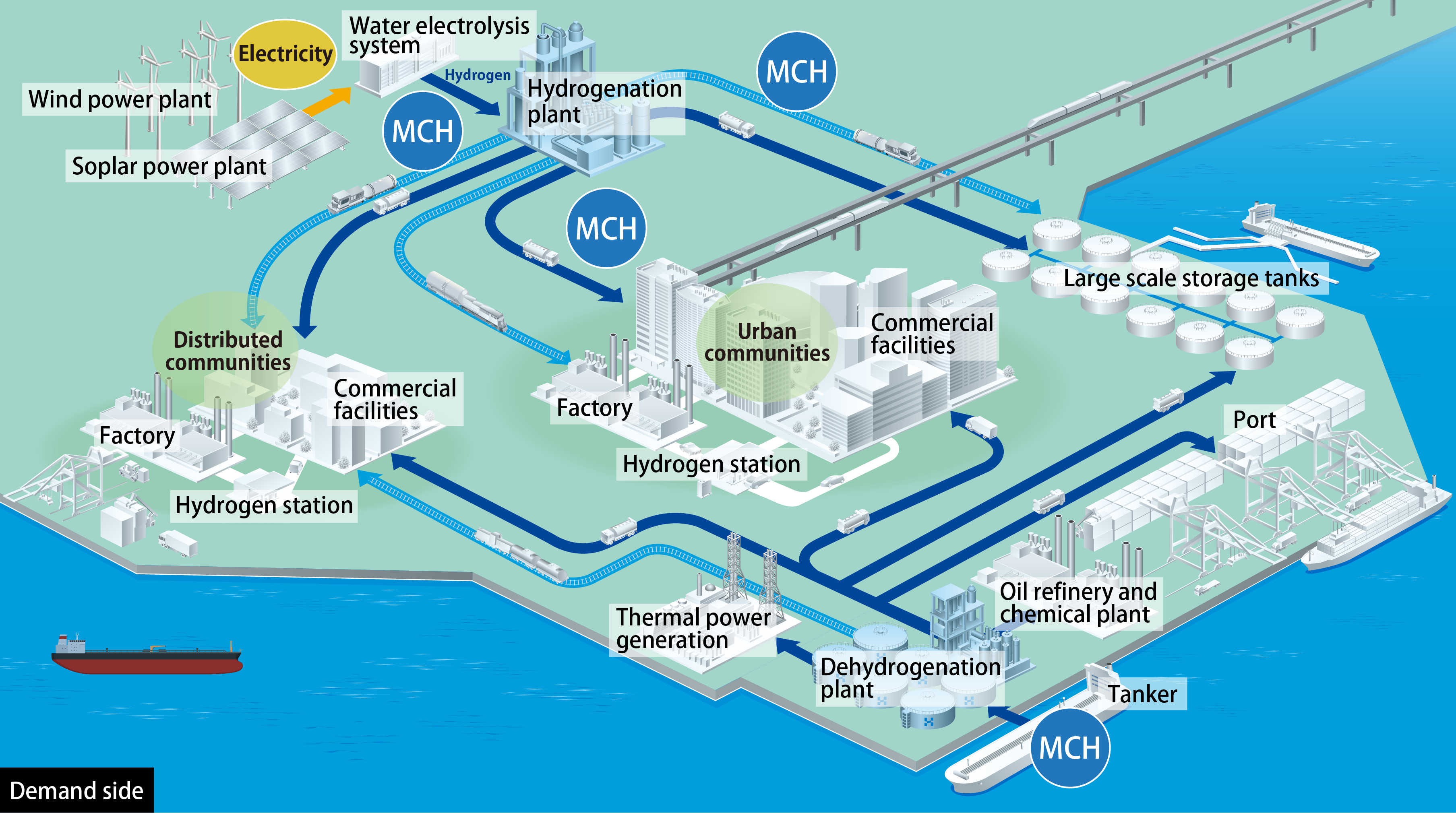

Chiyoda’s Hydrogen Community Vision

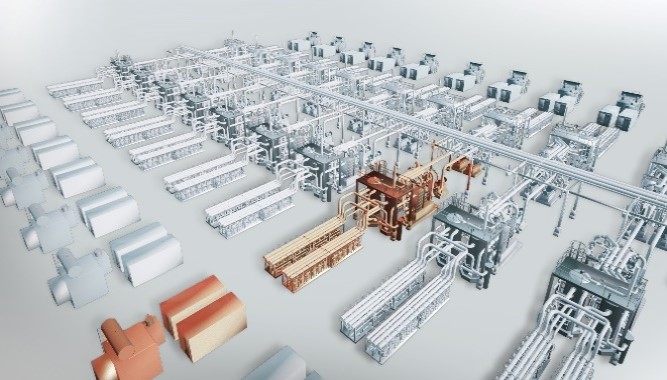

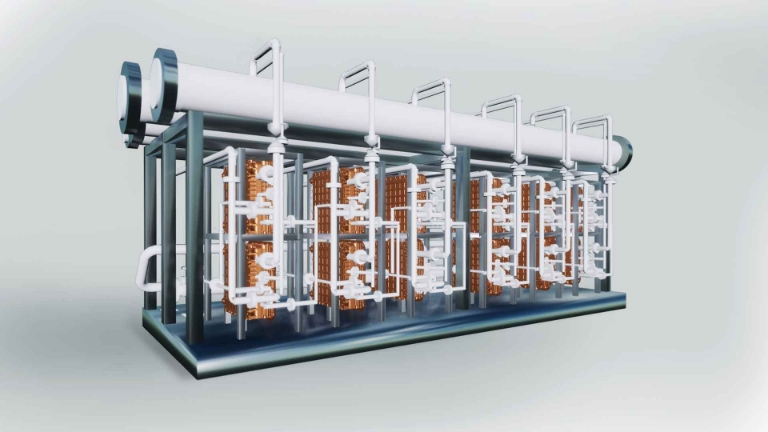

(Highly integrated water electrolysis stack group, produced by Toyota)

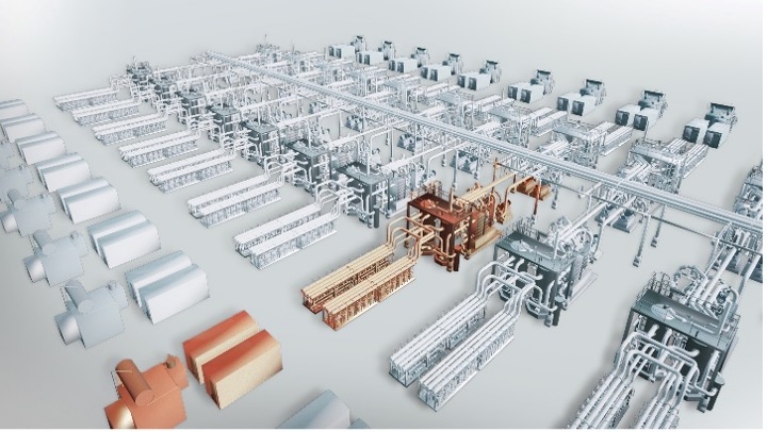

(Smart scalable engineering by Chiyoda)

──What initiatives are you promoting?

Hydrogen Production

Inoue

Firstly, hydrogen production from resources such as water, renewable energy and fossil fuels, including petroleum and natural gas. We are collaborating with Toyota Motor Corporation to develop a large-scale water electrolysis system that produces hydrogen from water.

By integrating and optimizing Toyota's fuel cell technology for electrolysis cell stacks with our strengths in process plant design and large-scale plant construction technology, we aim to develop competitive large-scale water electrolysis systems to meet the rapidly expanding domestic and international hydrogen production market.

We are also collaborating with Hazar Group Ltd. in Australia and Chubu Electric Power Co., progressing a development project using the Hazar process to produce hydrogen from methane.

Storing and Transporting Hydrogen

Inoue

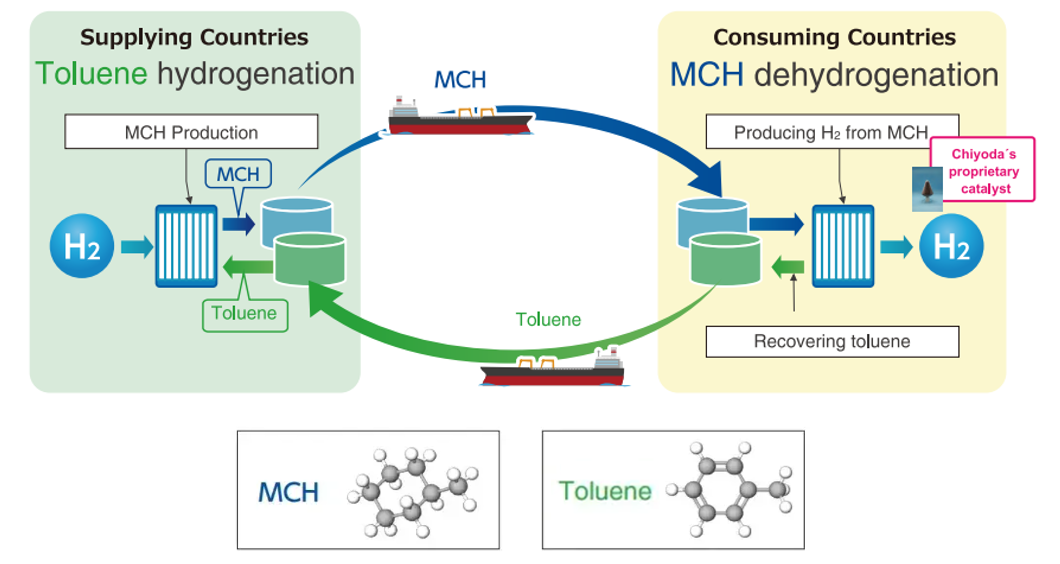

Chiyoda has developed technology to safely and efficiently store and transport hydrogen using Methylcyclohexane (MCH) as a Liquid Organic Hydrogen Carrier (LOHC) and termed it the ‘SPERA Hydrogen System’ (after “Spera” : Latin for “Hope”). In 2020, we successfully completed the world's first world hydrogen supply chain demonstration project using the LOHC-MCH (SPERA Hydrogen System).

LOHC-MCH (SPERA Hydrogen System)

Ito

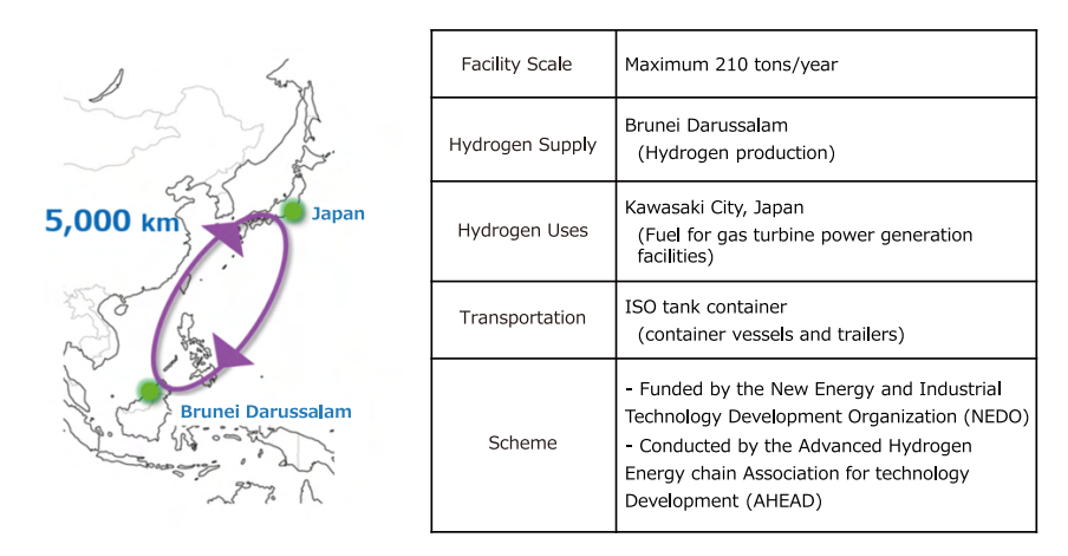

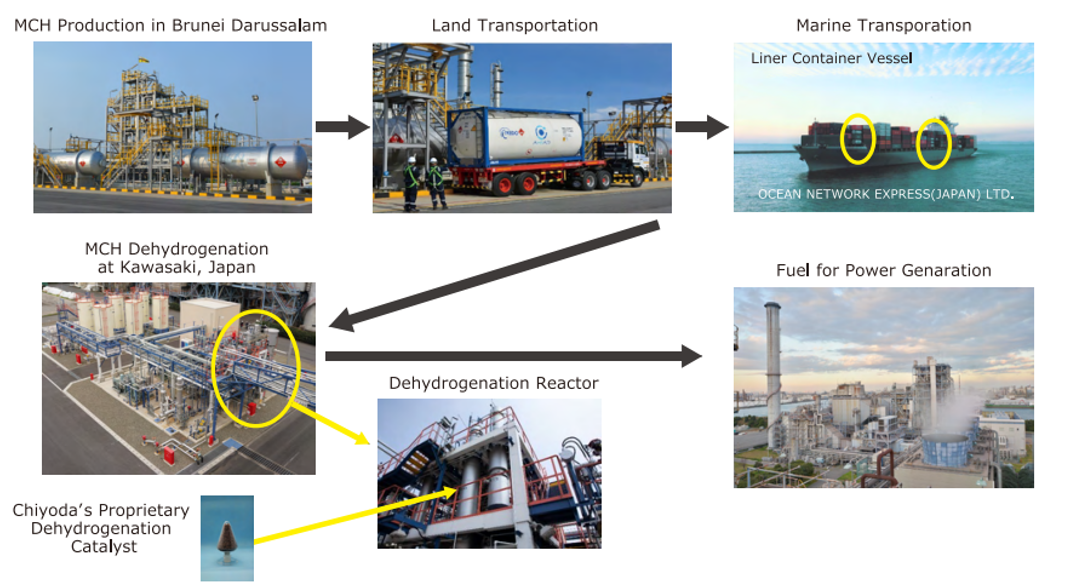

The demonstration project involved the hydrogenation of toluene to form MCH in Brunei Darussalam for storage and transportation to Kawasaki for subsequent dehydrogenation. The separated toluene is transported back to Brunei in a ‘continuous loop’ and the hydrogen is utilized in Japan. The project demonstrated the feasibility of long-term storage and transportation of commercial quantities of clean hydrogen worldwide.

Outline of the Demonstration Project

Flow Chart: MCH Production to using Hydrogen as Fuel for Power Generation

Inoue

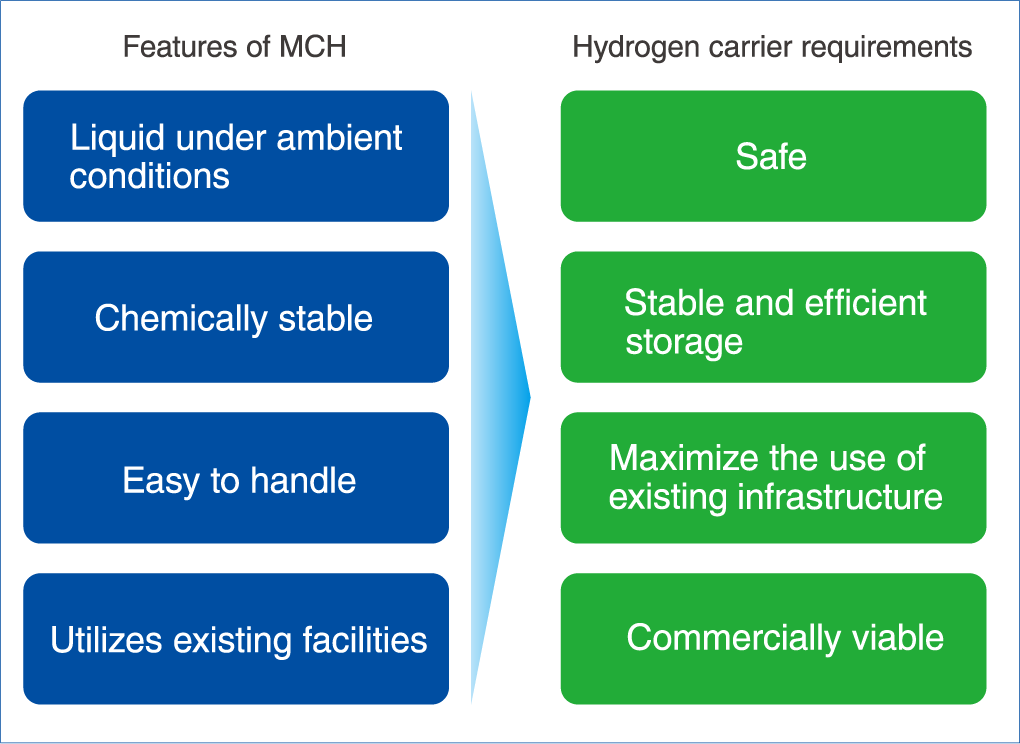

Hydrogen carriers used for storing and transporting hydrogen include MCH, ammonia and liquefied hydrogen. While ammonia and liquid hydrogen require low-temperatures, MCH has the distinct advantage of storing and transporting hydrogen at ambient temperature and atmospheric pressure, making it the most manageable hydrogen carrier. Significant cost savings also result from being able to utilize existing petroleum storage and transportation infrastructure under current international standards and regulations.

Utilizing hydrogen

Morikami

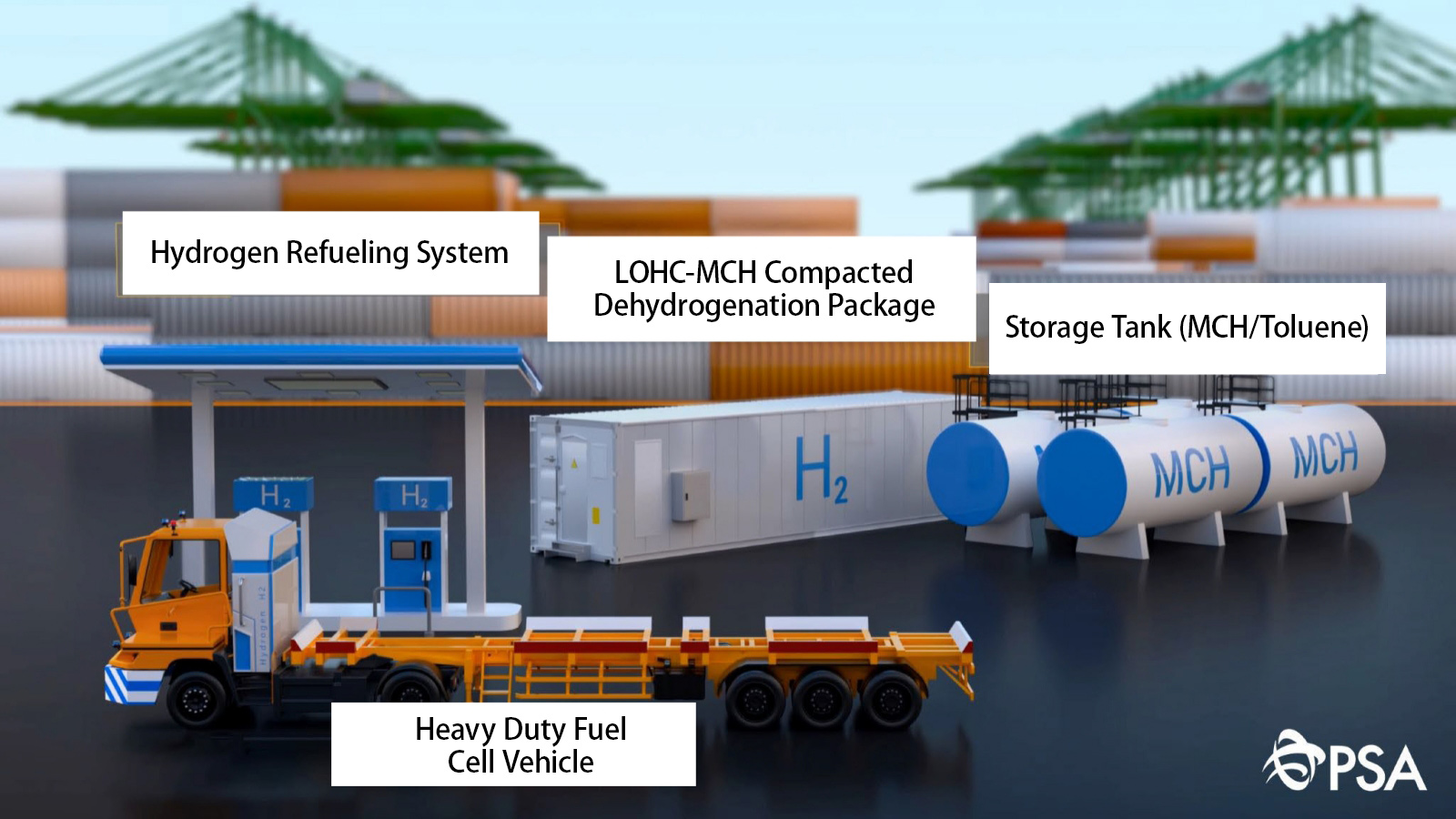

The international hydrogen supply chain project supplied hydrogen in the form of MCH from Brunei to the Mizue Power Plant of Toa Oil Co., Ltd at their Keihin Refinery in Japan, marking the first domestic use of hydrogen for power generation. In early 2024, Chiyoda commenced an MCH Dehydrogenation Refueling Station demonstration project in Singapore to operate heavy duty Fuel Cell Vehicles (FCV) with imported hydrogen at Pasir Panjang Terminal as the MCH Compacted Dehydrogenation Package in use for decentralized applications of imported hydrogen. Hydrogen is anticipated to be utilized in a multitude of industries, including power generation, fuel for transportation, petrochemicals and hydrogen-reduced ironmaking, as a raw material and heat source. It is important to provide a wide range of hydrogen carrier options, such as MCH, liquified hydrogen and ammonia, depending on the customer's environmental parameters, use and quantity requirements. We are an integrated engineering company that meets the needs of our customers.

Image of the hydrogen refueling demonstration system, using hydrogen imported into Singapore for large fuel cell vehicles .

Contributing to the Realization of a Hydrogen Society through Technologies that Deliver Optimal Solutions

Inoue

Although the LOHC-MCH (SPERA Hydrogen System) offers significant advantages for customers utilizing existing petroleum infrastructure, we also offer customers without access to existing infrastructure significant benefits through other cost-effective options.

As the world transitions towards clean energy, our mission as an integrated engineering company is to provide solutions without bias towards specific technologies, enabling customers to select their preferred hydrogen carrier medium, such as hydrogen or ammonia, aligning with our purpose of ‘Enriching Society through Engineering Value’.

Morikami

Although we naturally promote our ‘in-house’ developed, proprietary SPERA Hydrogen System technology, we also emphasize our open technology development for all forms of clean energy.