Overcoming the challenges to achieving commercialization by applying our catalyst and process development expertise

── We have discussed Chiyoda’s four decarbonization technologies. What strengths do Chiyoda possess to develop and implement these technologies? How will you overcome current challenges?

Hirohata

Chiyoda’s significant strengths are catalyst and process development expertise and experience. We excel in managing technology development and process design, with commercialization in mind from the early stages of development. We consider the data that should be collected and its development to scale-up in the shortest possible time through back-casting. Catalysts are essential for chemical product manufacturing and the resource and energy sectors because they reduce harmful substances and transform them into beneficial ones through chemical reactions. Our expertise in combining process development and catalyst development enables us to propose unique solutions for a wide range of social challenges.

Ichikawa

In the ammonia field, our strengths are advanced ammonia cracking technology and our in-depth understanding of ammonia in general, accumulated through our experience of commercialized equipment for ammonia synthesis plants. Ammonia as a fuel is attracting attention in the movement towards decarbonization and new methods of ammonia production are in demand towards utilization. We are currently developing Japanese-originated technology in collaboration with Tokyo Electric Power Company Holdings, Inc. and JERA Co., Inc, focusing on new catalysts for ammonia production aiming to reduce costs through lower temperatures and pressures compared to the conventional Haber-Bosch method.

Hirohata

One challenge is the requirement for large-scale, high-cost equipment to obtain more accurate data on the demonstration stage. We would like to demonstrate our technologies in a wider scale and harvest public opinion for consideration in business plans, aiming for early social implementation. We believe that these actions will help us secure development funds.

Kotani

Talking about our ammonia business, if a problem arises when integrating with a thermal power plant of JERA Co., Inc., the impact would be significant as electricity is a critical social infrastructure.

Low concentration CO₂ separation and removal technologies face many challenges before social implementation. For example, although we need large areas for equipment installation, cost reductions can be realized as the area required reduces.

Ichikawa

We need to connect our equipment to existing facilities for ammonia cracking technology. Such equipment should be small for easy and safe installation. We must keep thermal power plants operational while we install new technologies because they support critical infrastructure. We proceed with development carefully and gradually to reduce risks and apply ‘Safety in Design’ by simulating toxic ammonia concentrations diffusion in the event of an accident.

Matsumoto

We conduct joint research in collaboration with seven institutions to develop technology to produce ethylene from CO₂ and are always searching for more partners for early implementation. It is important to inform the general public of our technology and its application and we wish to display it to society through media collaboration.

Kotani

NEDO and the Ministry of Economy, Trade and Industry (METI) have requested Chiyoda to shorten the CO₂ separation and recovery technology development schedule, which we accept as expectations for the project are high.

Hirohata

The requirement for zero-emission power sources is increasing year by year and the demand for CO₂ separation, recovery and storage technologies is rising in line with the decarbonization momentum.

Accelerating technological development in collaboration with industry, academia and government

── What are the advantages of Chiyoda collaborating with industry, government and academia on projects?

Hirohata

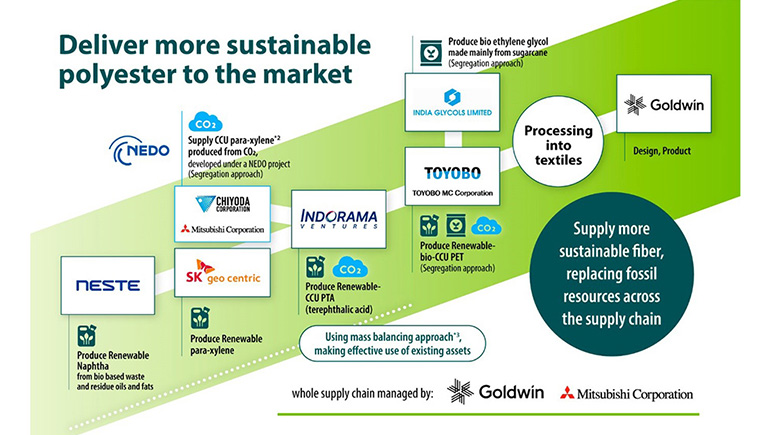

The catalyst developed by the University of Toyama for paraxylene production technology was commercialized for equipment use by HighChem Co., Ltd. Nippon Steel Corporation also supported commercialization with advanced analysis technology while Chiyoda managed process development and Mitsubishi Corporation managed business development. ENEOS Corporation, the largest domestic manufacturer of paraxylene, has recently joined the project. Partnership with such prominent users in each field is a significant strength for technology development and societal implementation.

Ichikawa

It is essential to be cohesive group because the development of ammonia cracking technology is expected to be time consuming. We have established a good cooperative working relationship with JERA Co., Inc. and NIPPON SHOKUBAI CO., LTD. Although it takes about 10 to 20 years to develop a catalyst, we were able to shorten the development period in collaboration with NIPPON SHOKUBAI CO., LTD., who developed the base catalyst before the project commenced which was a significant advantage.

Matsumoto

We had started to develop the technology to produce ethylene from CO₂ before the project was launched but there had been no discussions regarding the source of CO₂. Shimizu Corporation proposed installing a CO₂ recovery device in building ducts, and that’s how we created the new ‘urban DAC system’. The perspective unique to general contractors is vital because engineering companies like ours do not have such perspectives. Collaborating with partners from the brainstorming phase enables us to view things differently.

Kotani

In developing CO₂ separation and recovery technology with JERA and RITE, we effectively allocate roles based on company strengths. Vendors and manufacturers also offer support as we endeavor to resolve issues. A valuable asset is our strong working relationships with partners.

── What is important when collaborating with customers and partners?

Kotani

On the technical side, it is important to share the goal and work towards achieving it together. On the business side, it is necessary to build relationships for effective communication. We need to discuss participant company share of investments and allocate risks and responsibilities. Respect, honesty and transparency are key.

Matsumoto

On projects such as this, it is essential to establish and share common goals with partners.

Ichikawa

I agree. It is crucial for partners to progress their work through a common goal, especially during commercialization to ensure that each participant makes a profit.

Hirohata

Achieving milestones one by one based on shared goals by utilizing each company’s strength and maintaining balance among partners is essential. One of the reasons why Chiyoda is a partner is our outstanding human resources who excel in problem-solving and who have an integrative aptitude with the capability to complete projects. We are proud to be a member of this project.

Becoming a leader in the decarbonization field and contributing to the early social implementation of decarbonization technologies.

── Finally, please share your visions for the future.

Ichikawa

I feel a heavy responsibility as a member of this project because ammonia cracking technology is crucial for Japan, a country with limited fossil resources. I would like to strive to overcome each challenge steadily and work on our goals until we achieve them.

Matsumoto

Even if we produce ethylene from CO₂, that technology alone cannot achieve a decarbonized society. A combination with other technologies is required for social implementation and wide diffusion. Ethylene plays a foundational role in many chemical products. I wish to popularize the use of the decarbonized technology for its effective application in a diverse range of chemical products.

Kotani

Recovering CO₂ as a useful carbon resource and reutilizing it to produce diverse carbon compounds is a promising strategy. This approach addresses climate change issues and contributes to securing a stable supply of new resources. I wish to contribute to a decarbonized society through the early implementation of the technology for efficient separation and recovery of CO₂.

Hirohata

Chiyoda is a global frontrunner in the field of the technology to produce paraxylene from CO₂. I wish to maintain the number one position and successfully commercialize the technology as soon as possible. I hope that clothing made from CO₂ will be available in stores by the early 2030s.

Aligning technology development with global decarbonization trends, I will continue striving to establish technologies for social implementation and commercialization, aiming for Chiyoda to become the leader in the decarbonization field.