Capturing Global Trends and Decarbonization Technology Development to Create New Businesses

── Firstly, please expand on the background behind Chiyoda’s decision to focus on decarbonization technologies.

Hirohata

The Paris Agreement was adopted in December 2015, setting goals to achieve a balance between emissions and absorption of greenhouse gases (including CO₂) in the second half of the 21st century. Since then, the call for decarbonization has become more prominent worldwide and most countries and companies are taking specific measures to achieve this goal.

In 1972, Chiyoda advocated the philosophy of ‘Energy and Environment in Harmony’ in a company’s booklet ‘Legacy for the 21st Century’ and committed to resolving energy and environment-related challenges through engineering and technological development. We have continued to advance this mission for over 50 years.

In 2019, we established the Frontier Business Division to contribute to solving social issues by utilizing our engineering expertise and providing new systems and solutions. The Frontier Business Division consists of the Technology Development Department, responsible for research and development and the Business Innovation Department, responsible for business development. The two departments collaborate with each other from the initial stages of technological development, including commercial feasibility, and create new businesses to contribute to environmental conservation.

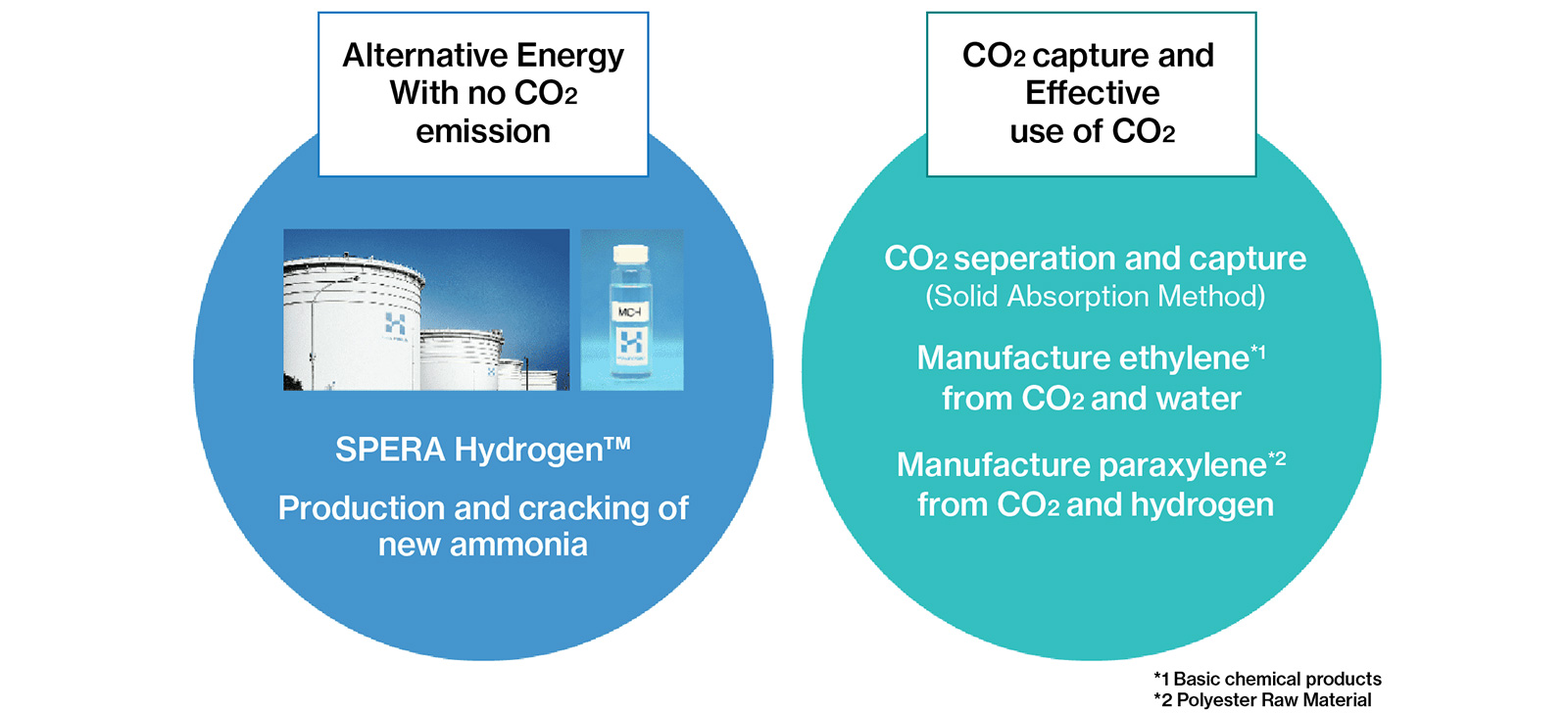

With the growing transition to a carbon-neutral society, we have positioned decarbonization technology as a growth strategy to create new businesses. We are developing decarbonization technology to separate and recover low concentration CO₂ from natural gas power plant exhaust gas, synthesis of ethylene by electrolytic reduction of CO₂, synthesis of paraxylene from CO₂ and hydrogen and production of hydrogen as power generation fuel from ammonia. These projects were adopted by the New Energy and Industrial Technology Development Organization (NEDO)*.

- An institution that creates innovation and promotes research and development for the realization of a sustainable society as an ‘innovation accelerator’ through the development and demonstration of high risk innovative technologies and promoting social implementation.

Chiyoda's main initiatives in decarbonization technologies

Separation and Recovery of Low Concentration CO₂ from Natural Gas Power Plant Exhaust Gas

── What are the features of Chiyoda's technological developments to separate and recover CO2 compared to conventional ones?

Kotani

We are developing Japanese-originated technology to separate and recover low concentration CO₂ from natural gas power plant exhaust gas with lower costs. Technologies to separate and recover high concentration CO₂ from coal-fired power plants (12-14% concentration), cement plants, steel mills etc have already been put to practical use. Practical application of technologies for low concentration CO₂ of 3-5% emitted from natural gas power plants has not been achieved however, because of cost. Separating CO₂ from gas with low concentration of CO₂ requires large amounts of energy, and the quantity of gas being processed is significantly larger compared to the that of CO₂ being recovered from the gas, leading to larger equipment sizes and higher operating costs. Our technology development aims to solve these cost issues.

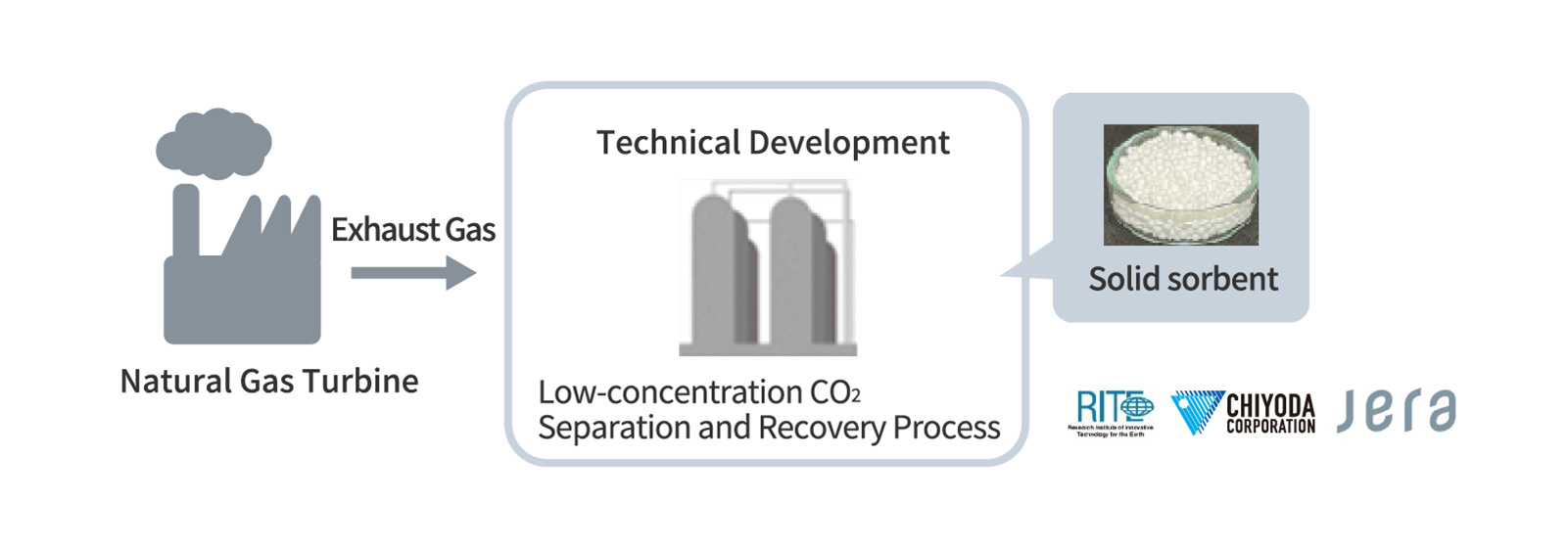

The project is jointly promoted by three companies: JERA Co., Inc., Research Institute of Innovative Technology for the Earth (RITE), a public interest incorporated foundation, and Chiyoda. JERA Co., Inc. has the largest natural gas power capacity in Japan and provides advice on development and technology introduction from the user's perspective. RITE develops solid absorbents that efficiently absorb low concentrations of CO₂, greatly reduce CO₂ separation and recovery costs, and realize smaller equipment. As the JV leader, Chiyoda develops processes and equipment to use such solid absorbents.

The project is divided into 3 phases: In Phase 1, we developed solid absorbents and the conceptual design of commercialized equipment. Phase 2 commenced in January 2025 and we plan to install a boiler with the recovery of 100 kg CO₂/day at our research institute for bench tests. We will collect the data required for scaling-up and check operation. In Phase 3, we will conduct operational demonstrations using the exhaust gas from an actual thermal power plant. The daily amount of CO₂ recovered is expected to be about 100 times higher than that recovered in Phase 2. Our goal is to commercialize large-scale equipment by the end of fiscal year 2030.

Conceptual Diagram of a Process for Separation and Recovery of Low-concentration CO₂ from Natural Gas-fired Power Plant Exhausted Gas

Message from JERA

Synthesizing Ethylene through Electrolytic Reduction following Separation and Recovery of CO₂ from the Atmosphere

── Please expand upon ethylene production technology for the effective use of CO₂.

Matsumoto

Ethylene is a basic chemical derived from fossil fuels such as petroleum and natural gas and is used in chemical products. We are a member of NEDO's moonshot R&D program and have been working on developing technology to synthesize ethylene through electrochemical reduction of CO₂ diffused in the atmosphere, in collaboration with industry, academia and government, such as The University of Tokyo, Osaka University, RIKEN, Shimizu Corporation, Furukawa Electric Co., Ltd., UBE Corporation, and Maxell, Ltd.

The concentration of CO₂ in the atmosphere is low, about 0.04%. To capture the CO₂, large quantities of air needs to be passed through the equipment which requires upsizing and a large areas for installation (generally suburban areas). We also propose a new ‘urban Direct Air Capture (DAC) system’ to use the air conditioning system of a building for DAC. In collaboration with Shimizu Corporation, we are developing small-scale equipment that fits into air conditioning equipment in buildings and are endeavoring to integrate the CO₂ recovery process and electrolytic reduction process in the system.

The manufactured ethylene is collected at the factory and transformed into products such as ethylene glycol, an automobile antifreeze, or butadiene, a synthetic rubber to meet market demands. Ethylene has the potential for use in many chemical products and we will continue case studies focusing on commercial viability.

We plan to demonstrate experiment at the laboratory in 2025, followed by scaling-up and commercialization planning, aiming to enter into the pilot demonstration phase in 2029. We are advancing towards social implementation, aiming for the total amount of recovered CO2 to exceed the total amount of CO2 in the atmosphere and exhaust gases, and wish to promote this initiative to realize a decarbonized society.

Message from Professor, The University of Tokyo

In our Moonshot Project, we are developing groundbreaking technology to capture CO2 from urban buildings and convert it into chemical raw materials for products such as clothing, PET bottles and tires. The energy required for this process is sourced from solar and wind power, and the system is designed to be compact enough to fit into limited spaces, such as building basements, by using the principles of electrochemical systems like fuel cells. Imagine breathing inside a building, where the CO2 we exhale is transformed into chemical products, and the oxygen generated during the process is absorbed back into the atmosphere — creating a new value that allows us to experience being part of nature’s cycle, even indoors. Chiyoda is a key player in implementing plants into society, supporting our everyday lives, and excels in project management, bringing together diverse stakeholders to successfully execute complex projects. This is a unique strength derived from applying chemical engineering—a multidisciplinary science—into real-world applications. Chiyoda’s expertise and dedication are contributing enormously to our project, enabling us to achieve world-leading outcomes.

Masakazu Sugiyama

Director and Professor,

Research Center for Advanced Science and Technology

The Univetsity of Tokyo

Manufacturing Sustainable Polyester Fibers from CO₂ and Hydrogen

── Please tell us about paraxylene production technology for the effective use of CO₂.

Hirohata

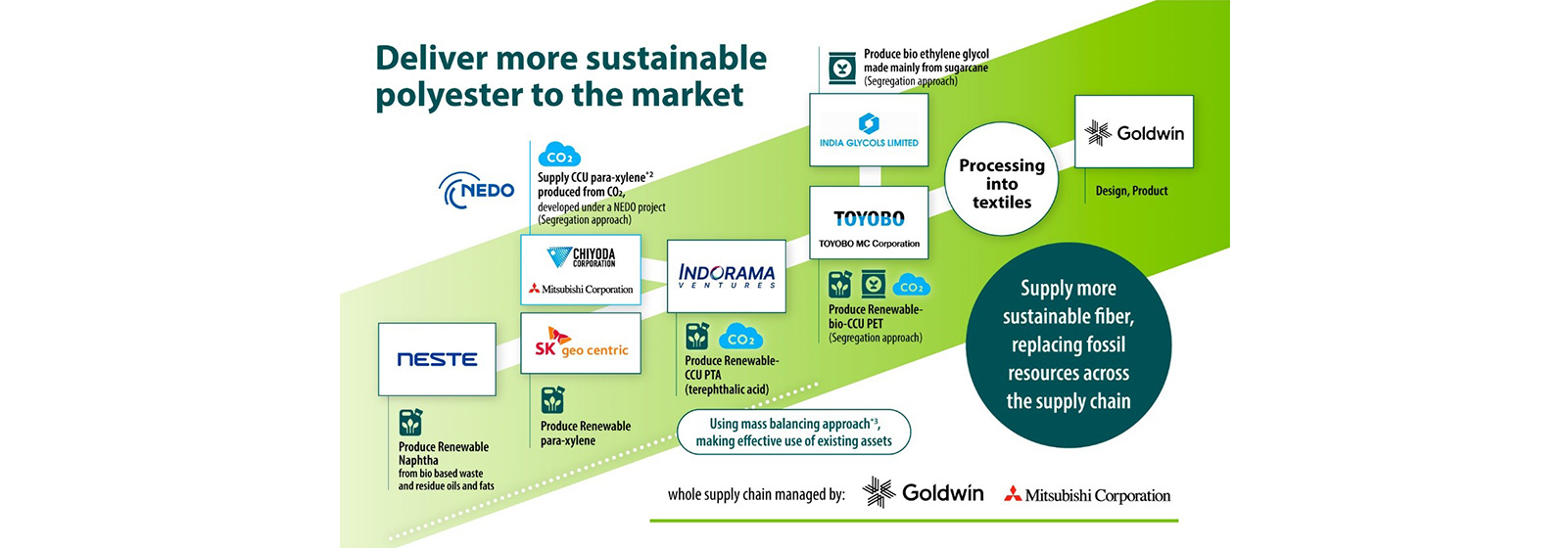

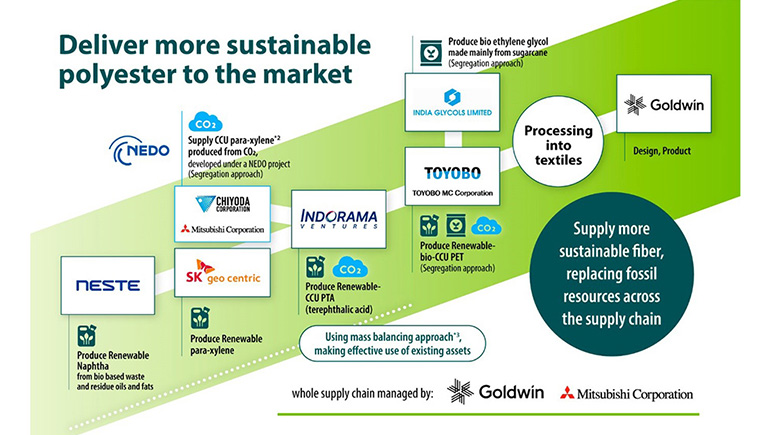

Paraxylene is a basic chemical widely used as a raw material for plastic bottles and polyester fibers. Paraxylene is a crude oil-based chemical, but we are developing the world's most advanced technology to produce it using CO₂ and ‘green hydrogen’; hydrogen derived from renewable energy.

Let me explain in more detail. We synthesize paraxylene from CO₂ and hydrogen under high temperature and high pressure and pass them through an independently developed catalyst. The key feature of our technology is a higher synthesis ratio of paraxylene compared to conventional methods. We currently plan to utilize CO₂ recovered from factory emissions but, in future, are willing to also use CO₂ captured directly from the atmosphere.

This technology is being developed in collaboration with the University of Toyama, Nippon Steel Corporation, HighChem Co., Ltd., Mitsubishi Corporation and ENEOS Corporation. Chiyoda is responsible for process development (scaling up from the laboratory level to commercialized equipment). We constructed a small pilot plant in Chiyoda’s Koyasu Office Research Park in 2022 and successfully manufactured compounds, mainly composed of CO₂-derived paraxylene. A third party successfully isolated (manufactured and extracted) paraxylene from these compounds using conventional techniques.

We formed a partnership with Goldwin Inc., in 2024, a company renowned for brands such as THE NORTH FACE, and established a supply chain in collaboration with seven companies across five countries for more sustainable polyester fiber utilizing CCU technology. In this initiative, the CO₂-derived paraxylene produced from our small pilot plant has been used as a raw material for the polyester fiber. It is the world's first attempt to produce CO₂-derived paraxylene in collaboration among upstream material companies and downstream apparel companies. The polyester fiber was used for the uniforms of Japanese and Korean climbers and T-shirts.

The project has been extensively covered by the media. Providing information and products into the market and popularizing them according to public reaction is required for investigating business partners, funding and increasing the feasibility of the business plan. The apparel industry, in particular, has a high affinity with this technology due to its strong awareness of sustainability. We aspire to use the CO₂-derived paraxylene as a raw material for plastic bottles and engineering plastics (plastics with superior strength and heat resistance).

CO₂-derived Paraxylene Supply Chain Conceptual Diagram

Message from HighChem Co., Ltd.

In a world where the decarbonization of fuels is advancing, the decarbonization of paraxylene—a chemical product—and polyester, primarily made from paraxylene, feels more tangible and relatable to the general public. I am delighted with this opportunity to execute this project with Chiyoda, as its implementation carries a profound carbon-neutral message that reaches all of society. I am particularly impressed by Chiyoda Corporation's approach to technological developments within the project and their professional execution based on fundamental principles across many aspects. Chiyoda’s project management methods and practices have provided valuable learning experiences for me and this project will impact the world in the future. We continue to strive for excellence and drive this important mission forward.

Dai Qipeng

Carbon Innovation Sec. Manager,

Sustainability & Innovation Division,

C1 Division

HighChem Co., Ltd.

Generating Hydrogen for Power Generation from Ammonia

── Demand for hydrogen as a next-generation energy source is attracting attention because it does not emit CO₂ during combustion. Please tell us about the technology for extracting hydrogen from ammonia.

Ichikawa

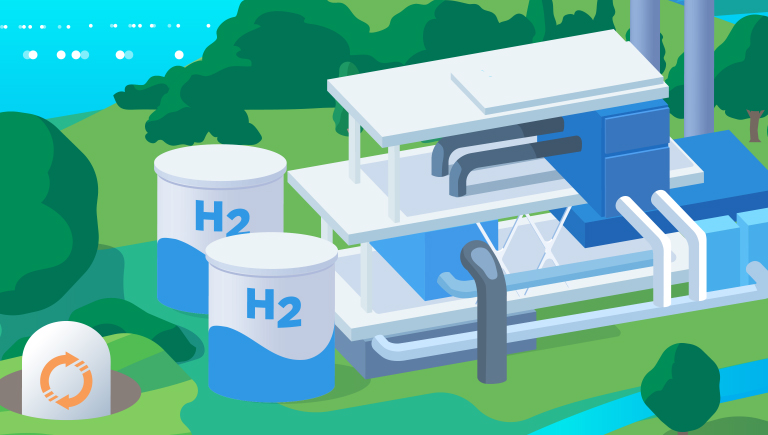

Ammonia is expected to be an energy carrier for low-cost transportation and storage of hydrogen. Although technologies for synthesizing ammonia from hydrogen and nitrogen and transporting ammonia have already been commercialized, plant based on the technology for generating hydrogen by cracking (decomposing) ammonia on a large scale is hardly used. If the technology to generate hydrogen at low cost through large-scale ammonia cracking is completed, we can produce low-cost hydrogen domestically using inexpensive ammonia imported from overseas and use hydrogen as an energy source for industries such as power generation. It is therefore essential to improve ammonia cracking technology and reduce costs.

In ammonia cracking, ammonia is decomposed into hydrogen and nitrogen through heat. Cracking technology is divided into two categories: external heating and Autothermal Reforming (ATR). In the external heating method, mainly used by overseas licensors, a temperature of approximately 1,000℃ is required to facilitate the decomposition reaction, and external heating, provided by electricity or burning fossil fuels, is required. For the ATR method, adopted by Chiyoda, the required heat is self-supplied by burning ammonia on a catalyst with oxygen. There is no need to install a burner in the heating furnace and no need to prepare a combustion furnace for external heating. Using this method, the temperature of the reactor can be maintained at 700℃ or lower to reduce CAPEX and OPEX.

This technology development is conducted in collaboration with JERA Co., Inc. and NIPPON SHOKUBAI CO., LTD. Catalyst performance verification has been executed on laboratory equipment under identical temperature and pressure conditions as the commercialized equipment, repeating using ‘trial and error’ because there are many issues to be resolved for large-scale commercialization. Chiyoda is also executing evaluation on; 1) process performance to raise the temperature and pressure required for the decomposition reaction of ammonia, 2) the performance of the heat recovery process, 3) the thermal efficiency of the entire system of the plant and 4) economic efficiency. Comments and proposals from JERA Co., Inc. are reflected in the technology development and the goal is to scale up the technology to generate large amounts of hydrogen to produce power generation fuel.

Providing cutting-edge solutions for the world's energy challenges is JERA's mission and, as a pioneering player, we aim to commercialize solutions using low-carbon fuels such as hydrogen, ammonia and CCS. The project with Chiyoda is essential for achieving this goal, and expectations within JERA are high. We are approaching the project with a strong sense of purpose and motivation. Chiyoda has long been at the forefront of engineering and technological development to address energy and environmental issues and their role in designing and developing processes that integrate the performance of catalysts and absorbents into power generation systems is vital. Chiyoda has specialists capable of tackling challenging technological developments such as this project and, in relation to the development of cracking technologies, Chiyoda places high priority on safety evaluations and measures when handling hydrogen and ammonia. We plan to leverage Chiyoda’s extensive domestic and international expertise. While the path to establishing this technology is still a ‘work in progress’, we bring together the strengths of each company to ensure the technology can be implemented into society.

Takashi Nagao

General Manager,

Technology Development Unit,

Technology Strategy Group,

O&M Engineering Strategy Division

JERA Co., Inc.