The North Field East (NFE) LNG project

- Client

- QatarEnergy LNG

- Capacity

- 8.0 MMTY x4 trains

- Location

- Ras Laffan, Qatar

- Scope of Work

- Engineering, Procurement and Construction (EPC)

- Year of completion

- 2027(Planned)

Contributing to a stable supply of LNG though the engineering and construction of the world’s largest LNG plant.

The world's largest LNG plant

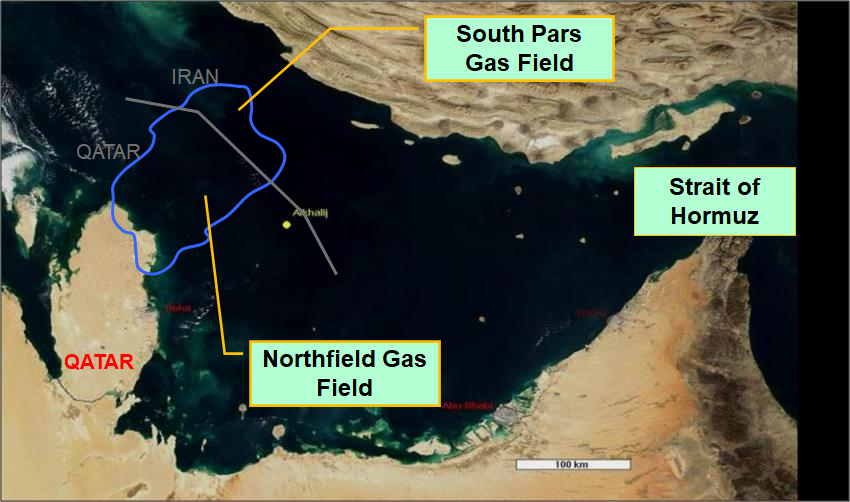

The project involves the engineering and construction of a series of four LNG production facilities using natural gas sourced from the North Field Gas Field, the world's largest gas field. The annual production capacity of 8 million tons is the largest in the world for a single series and the total production capacity of 32 million tons is also the world’s largest. As Qatar’s national project, the plant area, scale and number of workers involved is unprecedented and unmatched anywhere in the world.

Plant area

The plant area is 2,698,000 m2, equivalent to 58 Tokyo Domes, an area covering the Yokohama Minatomirai region.

Diverse and multinational talent, working as ‘One Team’.

The CTJV currently comprises approximately 1,200 staff members (as of January 2024) from Japan, France, India, the Philippines, Sri Lanka, Nepal and 47 other countries, working collaboratively as ‘One Team’ and is expected to mobilize over 45,000 workers during peak construction.

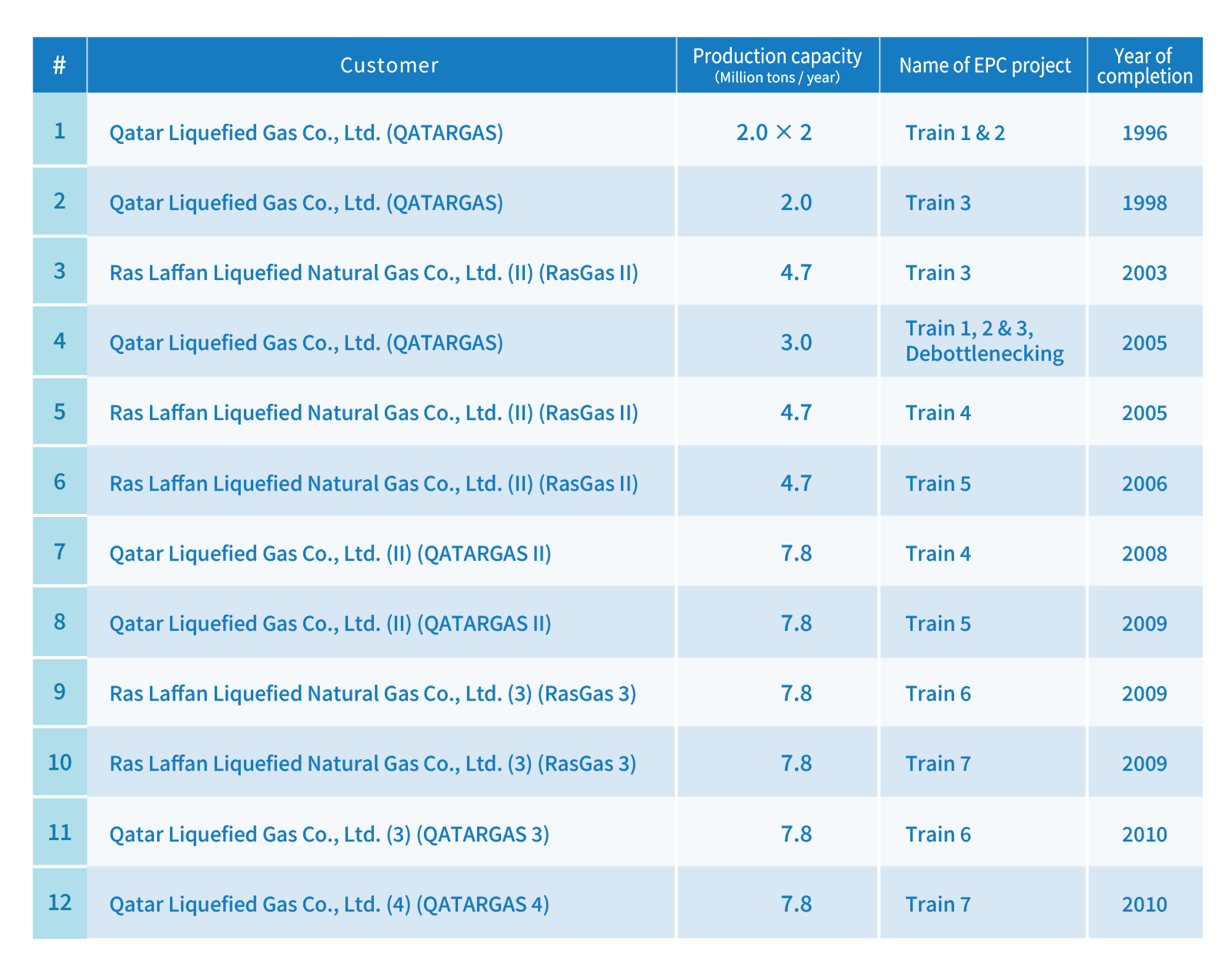

Leveraging our extensive experience in Qatar

Chiyoda has been involved in all fourteen series of LNG plants constructed in Qatar, executing the Engineering, Procurement and Construction (EPC) for twelve, including six with an annual production capacity of 7.8 million tons, identical to the NFE project and we have accumulated an unrivalled database of lessons learned (LL) for projects in Qatar to address project risks, critical for successful execution.

Chiyoda's track record of LNG plant construction in Qatar (EPC projects)

Enhancing project execution capabilities through the utilization of Chiyoda AWP

Large-scale projects, such as the NFE project, require large quantities of materials and equipment to be transported to site for construction according to the schedule and Advanced Work Packaging (AWP), a project management methodology developed collaboratively between the Construction Industry Institute (CII) and the Construction Owners Association of Alberta (COAA) to improve productivity and reduce costs in construction using industry best practices, is being applied on the project.

As a link between the engineering, procurement and construction, Chiyoda AWP is a complete EPC management system to improve efficiency in fabrication and construction execution and improves workforce productivity, benefiting large-scale and complex capital projects by aligning engineering and procurement deliverables with the construction sequence. Typically, construction work is divided into manageable work packages and, by aligning methodology, procedures and software tools to deliver information, materials, equipment and labor resources prior to commencement of construction, Chiyoda maximizes efficiency through increased productivity.

‘Objective 110’

CTJV has adopted ‘Objective 110 - One Team, One Step Further, Zero incidents & defects’, leveraging on the extensive experience gained from our successful track record in Qatar, maximizing our knowledge and incorporating the latest digital technologies. We are working collaboratively with customers, licensors and subcontractors as ‘One Team’ to ensure the success of this national project.