Chiyoda DX Initiative

Company-wide Acceleration of DX

We drive a hybrid transformation through DX—advancing

both ‘Corporate Transformation’ and ‘Industry Transformation’,

strengthening the foundation for becoming a stable and highly profitable company,

and ‘Enriching Society through Engineering Value.'

Top Message

The President & CEO and the CDO & CHRO provide an explanation of our company-wide DX strategy.(Japanese Only)

Representative Director, President & CEO and CSO

Koji Ota

Senior Executive Officer, CDO and CHRO

Masaki Kumagai

Vision

We operate the Company-wide Operational Execution Platform, positioned at the core of the Chiyoda DX Initiative, to drive Corporate Transformation. Through three co-creation domains — EPC Business Transformation, Operational Support, and Social Implementation — together with Core AI technology, the AI Process Simulator, we are advancing the transformation of industry while co-creating social value.

Corporate Transformation

Through the Company-wide Operational Execution Platform, we share continuously updated and structured data across the entire organization, enabling advanced management and governance while ensuring effective risk control.

EPC Business Transformation

By executing engineering (E), procurement (P), and construction (C) through the Digital EPC Platform, we enhance business agility — the ability to respond quickly and flexibly to changes in market conditions, customer needs, and technological advancements, thereby maintaining competitiveness and enabling sustainable growth.

Operational Support

Through plantOSTM, which supports plant operation, maintenance, and production enhancement by combining DX and physical solutions, we contribute to achieving business safety — safe and secure corporate activities which ensure business sustainability and flexibly adapt to environmental and social changes.

Social Implementation

Through the Scale-up Digital Twin, which supports life sciences and carbon neutrality via DX, we drive business innovation.

Core AI Technology

In promoting operational support and social implementation, our proprietary AI Process Simulator, developed specifically for the field of chemical engineering, serves as the engine - leveraging our data assets to drive innovation.

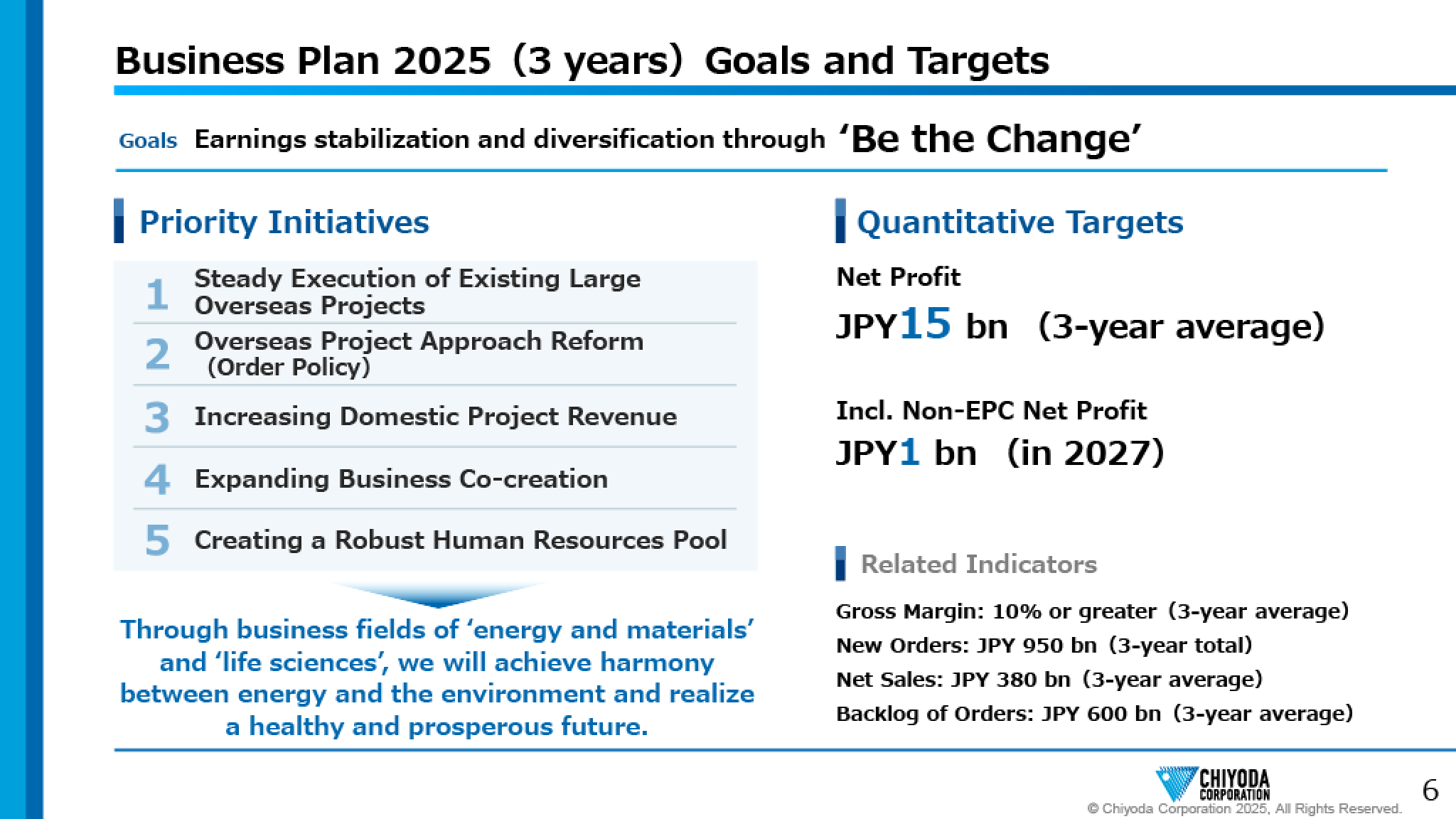

Position in the Management Plan

In our ‘Management Plan 2025 (Be the Change – Enriching the Future),’ the Chiyoda DX Initiative is positioned as an essential element for achieving Corporate Transformation by delivering on our ‘Priority Initiatives’ and ‘Quantitative Targets.’

Positioning of Management Plan 2025 and the Chiyoda DX Initiative

- The Priority Initiatives 1 to 3 are supported by DX for Corporate Transformation and DX in the EPC Business transformation Domain. These initiatives enhance EPC project execution capabilities and maximize individual performance.

- To advance Priority Initiative 4 (Expansion of Business Co-Creation), DX in the Operational Support Domain and DX in the Social Implementation Domain are essential. These initiatives deepen existing businesses and create new business models. By working in tandem, they broaden and accelerate business co-creation. Furthermore, progress in Priority Initiative 4 also contributes to advancing Priority Initiative 3.

-

Strengthening the use of AI core technologies across all initiatives

The ability to fully leverage AI is a critical element common to all DX domains.

Our core human resources will continue to drive DX across every domain.

Chiyoda DX Initiative Video

Leaders from each domain explain the Chiyoda DX Initiative and its key activities.(Japanese Only)

Track Record and Achievements

Introducing the key achievements and outcomes of the Chiyoda DX Initiative.

- Chiyoda Corporation and AVEVA Forge Strategic Partnership to Power plantOSTM*1 with AVEVATM CONNECT

- Introducing 3D Digital Twin Solutions to Mitsubishi Gas Chemical Company Inc. in Japan

- Partnership with Data Pioneer Solutions to Expand plantOS™ in North America and Japan

- Chiyoda Corporation Enters a Capital and Business Alliance with Basetwo to Enhance its Comprehensive O&M Solution, plantOS™

- The Use of Robotics and AI in Industry A Capital and Business Alliance with SENSYN ROBOTICS

- Completion of the Engineering, Procurement and Construction of a Battery Energy Storage System in Hokkaido Prefecture, Japan

- Achieve stabilized catalytic activity at RFCC device by utilizing EFEXIS® FCC AI Optimizer®

- Improved LNG Productivity using AI ('LNG Plant AI Optimizer') on PT Donggi-Senoro LNG